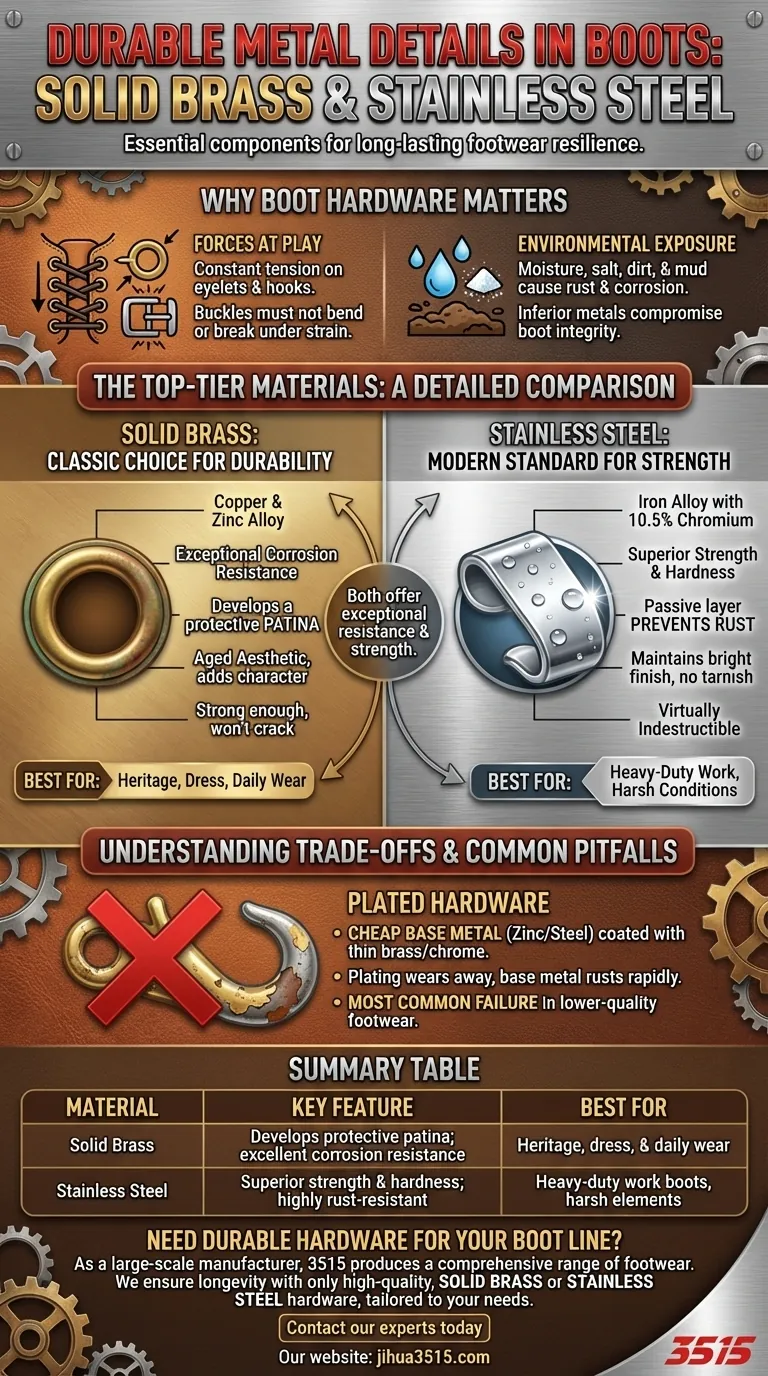

For durable metal details on boots, the standout recommendations are solid brass and stainless steel. Both materials offer exceptional resistance to corrosion and the strength needed to handle daily stress, ensuring that eyelets, buckles, and speed hooks do not become a point of failure.

The choice of metal for your boot hardware is a critical detail that dictates its long-term resilience. While both solid brass and stainless steel are excellent, the decision between them hinges on balancing the need for maximum strength against a preference for how the material ages aesthetically.

Why Boot Hardware Material Matters

The small metal components on a pair of boots are subjected to constant stress and environmental exposure. They are not merely decorative; they are functional anchor points that must withstand significant forces.

The Forces at Play

Every time you lace up your boots, you are putting tension on the eyelets and hooks. The buckles on straps must hold fast without bending or breaking. Weak materials will quickly fail under this repeated strain.

Environmental Exposure

Boot hardware is constantly exposed to moisture, salt, dirt, and mud. Inferior metals will corrode and rust, not only staining the leather but also compromising the structural integrity of the component itself, leading to breakage.

The Top-Tier Materials: A Detailed Comparison

Solid brass and stainless steel are the industry standards for high-quality footwear for good reason. They solve the core problems of strength and corrosion in different but equally effective ways.

Solid Brass: The Classic Choice for Durability

Brass is an alloy of copper and zinc. Its primary advantage is its exceptional resistance to corrosion. It does not rust like iron or steel.

Instead of destructive rust, brass develops a patina, a surface oxidation that protects the metal underneath. Many value this for its unique, aged aesthetic that adds character to the boot over time.

While not as hard as steel, solid brass is more than strong enough for the demands of boot hardware and will not crack or become brittle.

Stainless Steel: The Modern Standard for Strength

Stainless steel is an iron alloy containing a minimum of 10.5% chromium. The chromium creates a passive, invisible layer on the surface that prevents rust and corrosion with incredible effectiveness.

This material offers superior strength and hardness compared to brass, making it virtually indestructible in a footwear context. It is particularly resistant to saltwater and chemicals, making it ideal for true heavy-duty work boots.

Unlike brass, stainless steel maintains its bright, silvery finish and will not tarnish or develop a patina over its lifespan.

Understanding the Trade-offs and Common Pitfalls

The biggest mistake is confusing solid metals with plated ones. This is the most common point of failure in lower-quality footwear.

The Problem with Plated Hardware

Many boots use hardware made from a cheap base metal, such as zinc or low-grade steel, which is then coated with a micro-thin layer of brass or chrome.

This plating quickly wears away from friction, especially on speed hooks and eyelets. Once the plating is gone, the base metal is exposed to moisture and rapidly begins to rust and corrode, leading to failure.

Matching the Metal to the Boot's Purpose

Consider the primary function of the boot. For rugged work boots exposed to harsh conditions, the unyielding strength and chemical resistance of stainless steel is often the superior technical choice.

For heritage, dress, or daily wear boots, the aesthetic aging of solid brass can be more desirable, and its durability is more than sufficient for those tasks.

Making the Right Choice for Your Boots

Your selection should be guided by your primary goal for the footwear.

- If your primary focus is classic aesthetics and a unique patina: Choose boots with solid brass hardware for its warm color and graceful aging.

- If your primary focus is maximum strength and resistance to harsh elements: Choose boots with stainless steel hardware for its unyielding durability and corrosion-proof finish.

- If you are inspecting a potential purchase: Ask if the hardware is solid or plated, as this is a key indicator of the boot's overall quality and intended lifespan.

Ultimately, investing in boots with either solid brass or stainless steel hardware ensures these critical components will last as long as the leather they are set in.

Summary Table:

| Material | Key Feature | Best For |

|---|---|---|

| Solid Brass | Develops a protective patina; excellent corrosion resistance | Heritage, dress, and daily wear boots where aesthetics matter |

| Stainless Steel | Superior strength and hardness; highly rust-resistant | Heavy-duty work boots exposed to harsh conditions and chemicals |

Need durable hardware for your next boot line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We ensure the longevity of your products by using only high-quality, solid brass or stainless steel hardware, tailored to your specific needs and target market.

Contact our experts today to discuss your production requirements and get a quote.

Visual Guide

Related Products

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How are steel and composite toe caps tested for safety? Discover the Uniform Standard

- What are the key protective features of safety shoes? Essential Guide for Workplace Safety

- How often should safety toe boots be replaced? A Guide to Lifespan & Critical Signs

- How do steel, aluminium, and composite toe caps compare? Choose the Right Safety Toe for Your Job