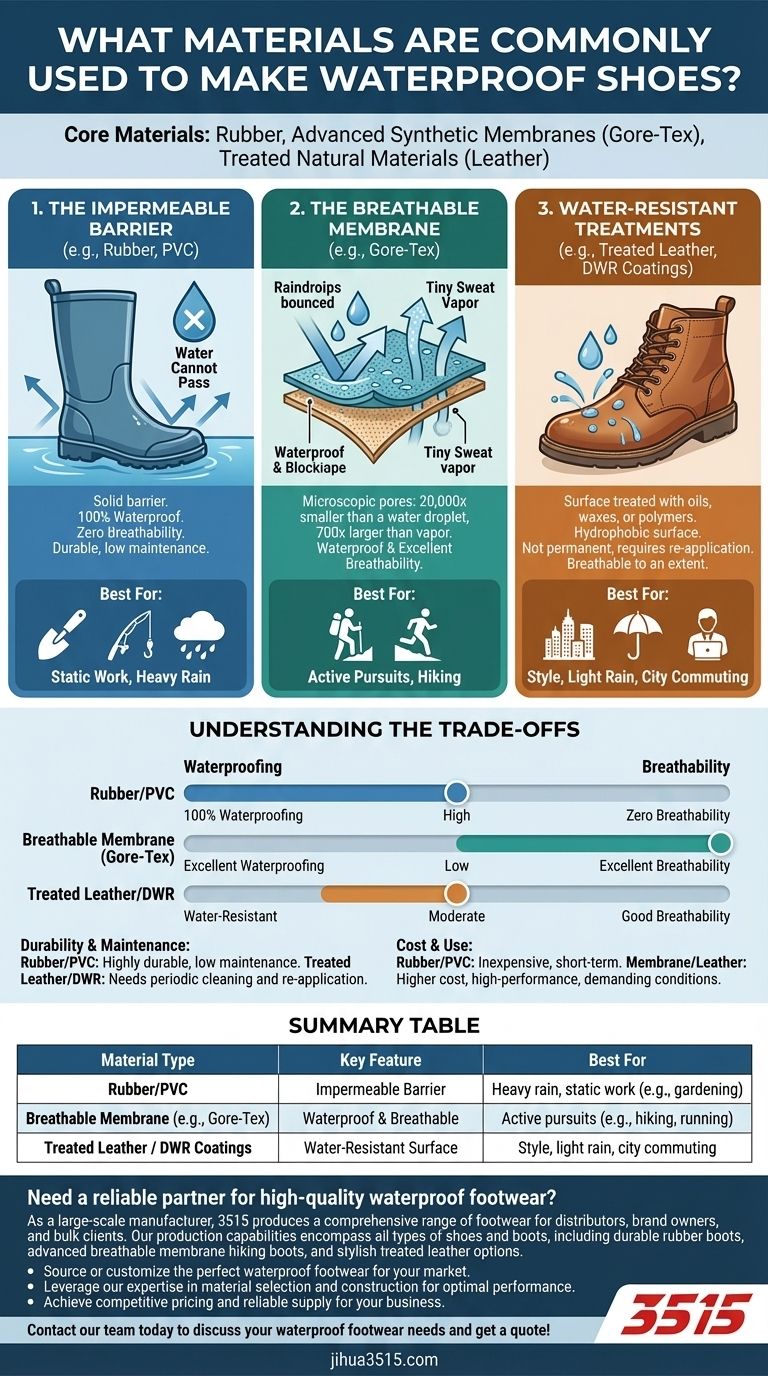

At its core, waterproof footwear is typically constructed from one of three material categories: inherently waterproof materials like rubber, advanced synthetic membranes like Gore-Tex, or natural materials like leather that have been specially treated to repel water.

The choice of a waterproof shoe is not about finding a single "best" material, but about understanding the fundamental trade-off between absolute water protection and a shoe's ability to breathe and manage sweat.

The Core Strategies for Waterproofing

The technology behind waterproof shoes generally falls into two distinct approaches: creating an impenetrable barrier or engineering a selective, breathable one.

The Impermeable Barrier

This is the most straightforward method. The material itself is a solid barrier that water cannot pass through.

The primary material in this category is rubber. It is naturally waterproof, durable, and relatively inexpensive, making it the classic choice for rain boots and work boots where total water protection is paramount.

Other synthetic materials like PVC (Polyvinyl Chloride) and PU (Polyurethane) function similarly, offering a completely sealed environment.

The Breathable Membrane

This advanced approach solves the primary drawback of impermeable barriers: a lack of breathability.

The most well-known example is Gore-Tex. It is not the shoe's outer material but a separate internal layer—a membrane with billions of microscopic pores per square inch.

These pores are 20,000 times smaller than a water droplet, preventing rain and moisture from getting in. Simultaneously, they are 700 times larger than a water vapor molecule, allowing sweat from your foot to escape.

This design keeps your feet dry from both external rain and internal perspiration, making it ideal for active use like hiking.

Water-Resistant Treatments

This category is distinct from true waterproofing and relies on treating the surface of a material.

Treated leather is a common example. Leathers like full-grain or nubuck are infused with oils, waxes, or polymers to make their surfaces hydrophobic, causing water to bead up and roll off.

Similarly, many synthetic fabric shoes use a Durable Water Repellent (DWR) coating. This is a chemical finish that provides a first line of defense against light moisture.

Understanding the Trade-offs

No single material is perfect for every situation. The right choice depends entirely on balancing competing needs.

Waterproofing vs. Breathability

This is the central conflict. A rubber boot offers 100% waterproofing but has zero breathability. Your feet will stay dry from the rain, but they can become damp and uncomfortable from trapped sweat.

A boot with a Gore-Tex membrane offers excellent waterproofing and excellent breathability. It is the superior choice for high-exertion activities but is more complex and costly to manufacture.

Durability and Maintenance

Rubber and PVC are highly durable and require little maintenance, though rubber can eventually crack with age and sun exposure.

Water-resistant treatments are not permanent. The DWR coating on a fabric shoe will wear off over time and must be reapplied. Treated leather needs to be cleaned and conditioned periodically to maintain its water-repellent properties.

Cost and Intended Use

The material directly impacts the cost and ideal application of the shoe. Simple rubber boots are inexpensive and perfect for short-term use in heavy rain or mud.

High-performance hiking boots using advanced membranes and high-quality treated leathers are significantly more expensive but provide the necessary performance for demanding conditions.

Making the Right Choice for Your Goal

Select your footwear by matching the material's strengths to your primary activity.

- If your primary focus is absolute protection in wet, static conditions (e.g., gardening, fishing): Choose a shoe made from an impermeable material like rubber or PVC.

- If your primary focus is staying dry during active pursuits (e.g., hiking, trail running): A shoe with a waterproof and breathable membrane like Gore-Tex is essential.

- If your primary focus is style and protection from light, occasional rain (e.g., city commuting): Treated leather or a shoe with a DWR coating will provide sufficient protection and comfort.

Ultimately, understanding how these materials work is the key to choosing footwear that keeps you dry and comfortable for your specific needs.

Summary Table:

| Material Type | Key Feature | Best For |

|---|---|---|

| Rubber/PVC | Impermeable Barrier | Heavy rain, static work (e.g., gardening) |

| Breathable Membrane (e.g., Gore-Tex) | Waterproof & Breathable | Active pursuits (e.g., hiking, running) |

| Treated Leather / DWR Coatings | Water-Resistant Surface | Style, light rain, city commuting |

Need a reliable partner for high-quality waterproof footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable rubber boots, advanced breathable membrane hiking boots, and stylish treated leather options.

We can help you:

- Source or customize the perfect waterproof footwear for your market.

- Leverage our expertise in material selection and construction for optimal performance.

- Achieve competitive pricing and reliable supply for your business.

Contact our team today to discuss your waterproof footwear needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Lightweight Breathable Sneakers with Wet-Traction Grip for Wholesale & Private Label

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What makes insulated boots ideal for outdoor activities in cold environments? The 5 Key Features Explained

- How does the insole contribute to comfort in motorcycle touring boots? Maximize Your Ride's Endurance

- What are the negative effects of aggressive lugs on good trails? Protect Your Run and the Trail

- Why are high-quality materials important for men's country boots? Invest in Durability & Long-Term Value

- Why is the sole of adventure motorcycle boots particularly important? The Key to On-Bike Control and Off-Bike Mobility

- Why is durability important when selecting outdoor shoes? A Guide to Safety & Long-Term Value

- What are the key features of snow boots? A Guide to Unbeatable Winter Protection

- Can hunting boots be repaired? Extend the Life of Your Favorite Gear