At their core, work boots and western boots are built from fundamentally different material philosophies. Work boots are constructed from heavy-duty materials like thick, full-grain leather and advanced synthetics such as ballistic nylon, prioritizing on-the-job protection and durability. Western boots, conversely, use lighter leathers and may feature exotic skins like snake or alligator, balancing traditional function with a distinct cultural and aesthetic style.

The materials in a boot are not an afterthought; they define its purpose. A work boot's construction is a direct answer to the demands of a hazardous environment, while a western boot's materials tell a story of heritage and personal expression.

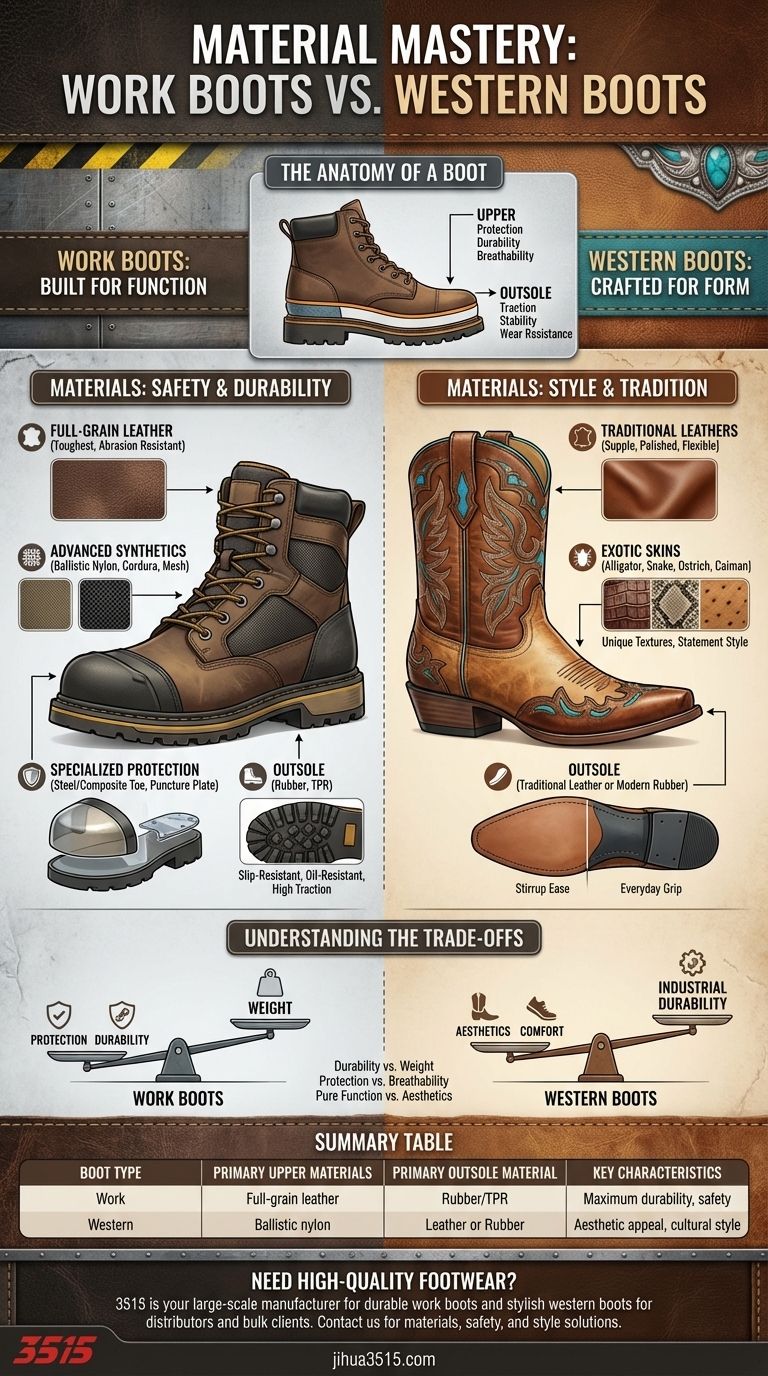

The Anatomy of a Boot: Uppers and Outsoles

Before comparing materials, it's critical to understand the two primary parts of any boot. The choice of material for each part is dictated by its specific function.

The Upper: Your First Line of Defense

The "upper" is everything above the sole. It protects your foot from impacts, abrasions, and the elements. Its materials dictate the boot's durability, flexibility, and breathability.

The Outsole: The Foundation of Performance

The outsole is the bottom layer that makes direct contact with the ground. Its material is chosen for traction, stability, and resistance to wear, ensuring a long-lasting and safe foundation.

Work Boot Materials: A Focus on Function

Work boots are engineered for industrial conditions. Every material is selected to maximize safety, durability, and resistance to harsh elements.

Full-Grain Leather: The Gold Standard

This is the toughest and most durable type of leather. It offers excellent resistance to water and abrasion, making it the premier choice for demanding environments where protection is paramount.

Advanced Synthetics: Lightweight Strength

Modern work boots often incorporate synthetic textiles. Ballistic nylon and Cordura are exceptionally resistant to tears and abrasions while being lighter than leather. Engineered mesh panels are added to enhance airflow and breathability in hot conditions.

Rubber and Composites: Specialized Protection

Rubber is frequently used in the upper for waterproofing. Critically, work boots often feature steel or composite safety toes and puncture-resistant plates embedded within their construction to meet safety standards.

The Outsole: Engineered for Grip

The outsoles of work boots are almost always made of rubber or thermoplastic rubber (TPR). These compounds are specifically designed for high traction, stability, and resistance to oil or slips on industrial surfaces.

Western Boot Materials: A Focus on Form

Western boots blend practicality with a rich cultural identity. Materials are chosen for their classic appearance and comfort, often with an emphasis on ornate detail.

Traditional Leathers: Supple and Stylish

Western boots typically use lighter and more polished leathers than their work-boot counterparts. This provides flexibility and a refined appearance suitable for both riding and casual wear.

Exotic Skins: A Mark of Distinction

A defining feature of many western boots is the use of exotic materials. Skins from alligator, snake, ostrich, or caiman are prized for their unique textures and patterns, serving as a statement of style.

The Outsole: Tradition Meets Modernity

Traditionally, western boots feature a smooth leather outsole, which is ideal for sliding in and out of a saddle's stirrup. However, many modern western boots now incorporate rubber outsoles to provide better traction and durability for everyday walking.

Understanding the Trade-offs

Choosing between these boots means understanding the inherent compromises in their design and material selection.

Durability vs. Weight

The heavyweight leather and puncture-resistant materials in a work boot offer superior protection but add significant weight. The lighter leathers of a western boot are more comfortable for casual wear but provide far less industrial-grade durability.

Protection vs. Breathability

Waterproof materials like rubber and heavily treated full-grain leather provide excellent protection from moisture but can limit airflow. Work boots with mesh panels offer better breathability at the potential cost of some water resistance.

Pure Function vs. Aesthetics

This is the clearest distinction. Every material in a certified work boot serves a functional purpose, from the steel toe to the slip-resistant sole. In contrast, materials like ornate stitching and exotic skins on a western boot are chosen primarily for their aesthetic and cultural value.

Making the Right Choice for Your Needs

Your decision should be guided by the primary demands you will place on your footwear.

- If your primary focus is safety and performance on a job site: Choose a work boot made from full-grain leather or abrasion-resistant synthetics, ensuring it has a certified safety toe and a rubber outsole.

- If your primary focus is style, tradition, and light-duty wear: A western boot crafted from traditional or exotic leathers will perfectly match your aesthetic and functional needs.

- If you need a hybrid of function and style: Seek out modern western boots that have been updated with durable rubber outsoles for improved traction and versatility in various environments.

Understanding these materials transforms your choice from a simple preference into a strategic decision for your specific purpose.

Summary Table:

| Boot Type | Primary Upper Materials | Primary Outsole Material | Key Characteristics |

|---|---|---|---|

| Work Boots | Full-grain leather, Ballistic nylon, Rubber | Rubber / TPR | Maximum durability, safety features (steel toe), slip resistance |

| Western Boots | Traditional leathers, Exotic skins (alligator, snake) | Leather (traditional) or Rubber (modern) | Aesthetic appeal, cultural style, comfort for casual wear |

Need High-Quality Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots and stylish western boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the perfect combination of materials, safety, and style for your market.

Let's discuss your specific needs: Contact our team today to explore our catalog and manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium KPU Injection Athletic Style Safety Shoes

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What factors should be considered when choosing the best work boots for a specific job? Match Your Boot to Your Work Hazards

- How do knee-high or ankle boots reduce injury risk? Essential Protection for High-Risk Work

- How can you identify high-quality boots? A Guide to Durable Materials and Construction

- What are PVC work boots made of? A Complete Guide to Their Durable, Waterproof Construction

- What specific features do Western work boots have for toe protection? A Guide to Steel & Composite Toe Caps

- How do leather and synthetic materials compare in work boots? Choose the Right Material for Your Job

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What makes work boots durable? The 3 Key Factors for Long-Lasting Footwear