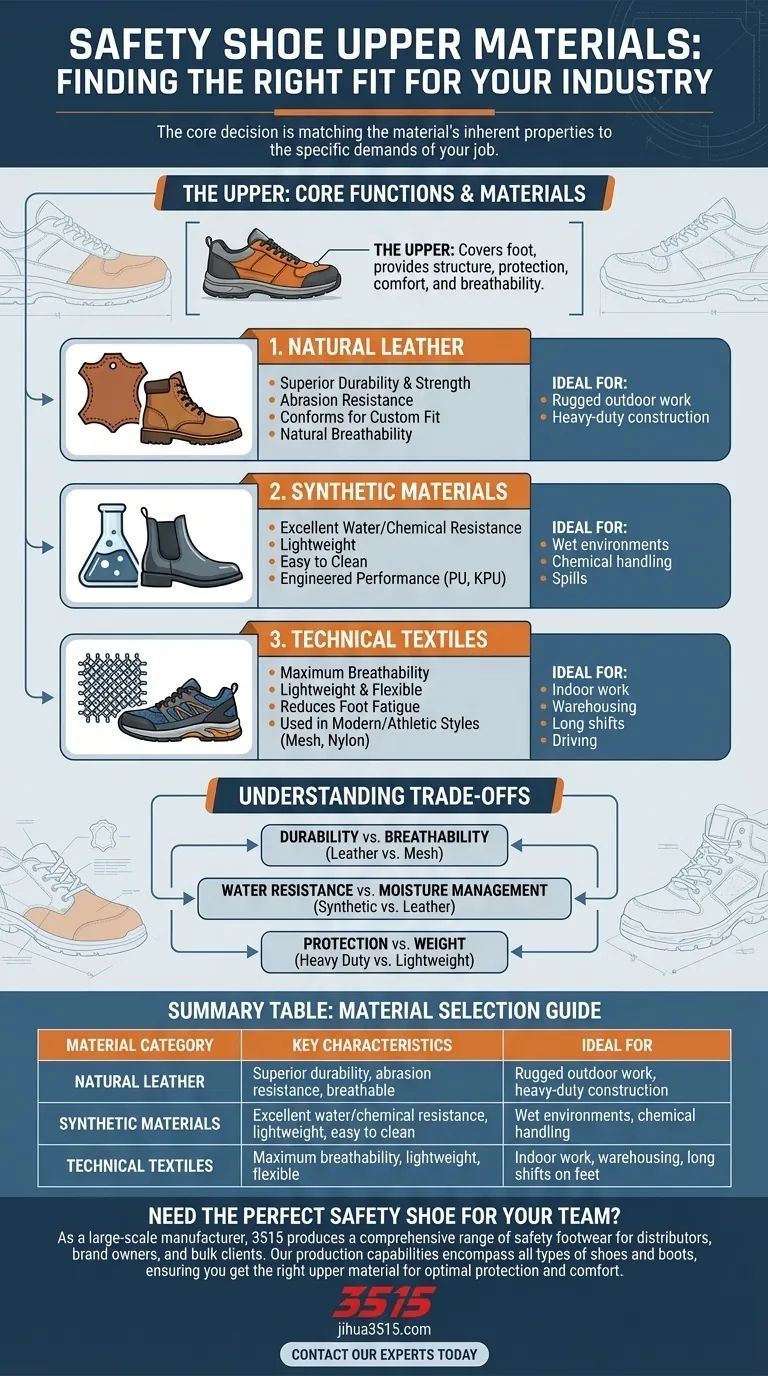

The upper part of a safety shoe is primarily constructed from one of three material categories: natural leather, synthetic materials, or technical textiles. While leather has traditionally been the standard for durability, modern synthetics and textiles offer specialized benefits for different work environments. The final choice always depends on balancing the need for protection, comfort, breathability, and resistance to specific workplace hazards.

The core decision in choosing a safety shoe upper is not about finding the single "best" material, but about matching the material's inherent properties to the specific demands of your job. Leather offers rugged durability, synthetics provide targeted chemical and water resistance, and textiles deliver lightweight, breathable comfort.

The Role of the Upper in Safety Footwear

Defining the "Upper"

The upper is the entire part of the shoe that covers the foot. This includes the sections covering the toes, the top (instep), the sides, and the back of the heel. It is the primary structure that is attached to the outsole.

Its Core Functions

Beyond simply holding the shoe together, the upper serves several critical functions. It provides structural support for the foot, protects against impacts and abrasions, shields the wearer from environmental factors like water or chemicals, and contributes significantly to the shoe's overall comfort and breathability.

A Deep Dive into Common Upper Materials

Natural Leather: The Classic Choice

Leather is the benchmark material for high-quality safety footwear due to its exceptional durability and strength. It naturally conforms to the shape of the foot over time, providing a custom fit.

Common types include full-grain leather, known for its toughness and cleanability, and suede or nubuck leather, which offer more flexibility. Its main advantages are abrasion resistance and a high degree of natural breathability and moisture-wicking capability.

Synthetic Materials: The Versatile Performer

This broad category includes materials like synthetic leather, polyurethane (PU), and KPU. These man-made materials are engineered to provide specific performance characteristics.

Their primary benefits are excellent water and chemical resistance, making them ideal for wet environments or industries where spills are a concern. They are also often lighter than natural leather and easier to clean.

Technical Textiles: The Comfort Specialist

Materials like mesh, nylon, and canvas are frequently used in modern safety shoes, particularly in athletic-style models. They are often combined with leather or synthetic reinforcements in high-wear areas.

The key advantages of textiles are their light weight, excellent flexibility, and superior breathability. This makes them ideal for indoor work, driving, or long shifts where foot fatigue and heat buildup are major concerns.

Understanding the Trade-offs

Durability vs. Breathability

A heavy-duty, full-grain leather upper will offer maximum protection against cuts and scrapes but may be less breathable in hot conditions. Conversely, a mesh upper provides fantastic airflow but offers minimal protection from abrasion on its own.

Water Resistance vs. Moisture Management

Synthetic uppers provide a superior barrier against external liquids but can sometimes trap sweat inside the shoe. Natural leather, while not inherently waterproof, breathes better to allow internal moisture to escape.

Protection vs. Weight

The most robust protective materials, like thick leather, add significant weight to the shoe, which can increase fatigue over a long day. Lighter textile and synthetic options reduce this strain but may offer less physical protection from impact or crushing forces.

Making the Right Choice for Your Environment

Ultimately, the ideal material is dictated by your daily tasks and workplace hazards.

- If your primary focus is heavy-duty construction or rugged outdoor work: Choose full-grain leather for its superior durability and all-around protection.

- If your primary focus is working with liquids, chemicals, or in consistently wet conditions: Opt for synthetic materials like PU or high-quality synthetic leather for their excellent resistance.

- If your primary focus is indoor work, warehousing, or long hours on your feet: Consider shoes with textile or mesh uppers for maximum breathability and lightweight comfort.

Selecting the right upper material transforms a safety shoe from a simple requirement into a critical tool for your daily performance and well-being.

Summary Table:

| Material Category | Key Characteristics | Ideal For |

|---|---|---|

| Natural Leather | Superior durability, abrasion resistance, breathable | Rugged outdoor work, heavy-duty construction |

| Synthetic Materials | Excellent water/chemical resistance, lightweight, easy to clean | Wet environments, chemical handling |

| Technical Textiles | Maximum breathability, lightweight, flexible | Indoor work, warehousing, long shifts on feet |

Need the perfect safety shoe for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right upper material—whether leather, synthetic, or textile—for optimal protection and comfort.

Contact our experts today for a customized solution that meets your specific needs.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?