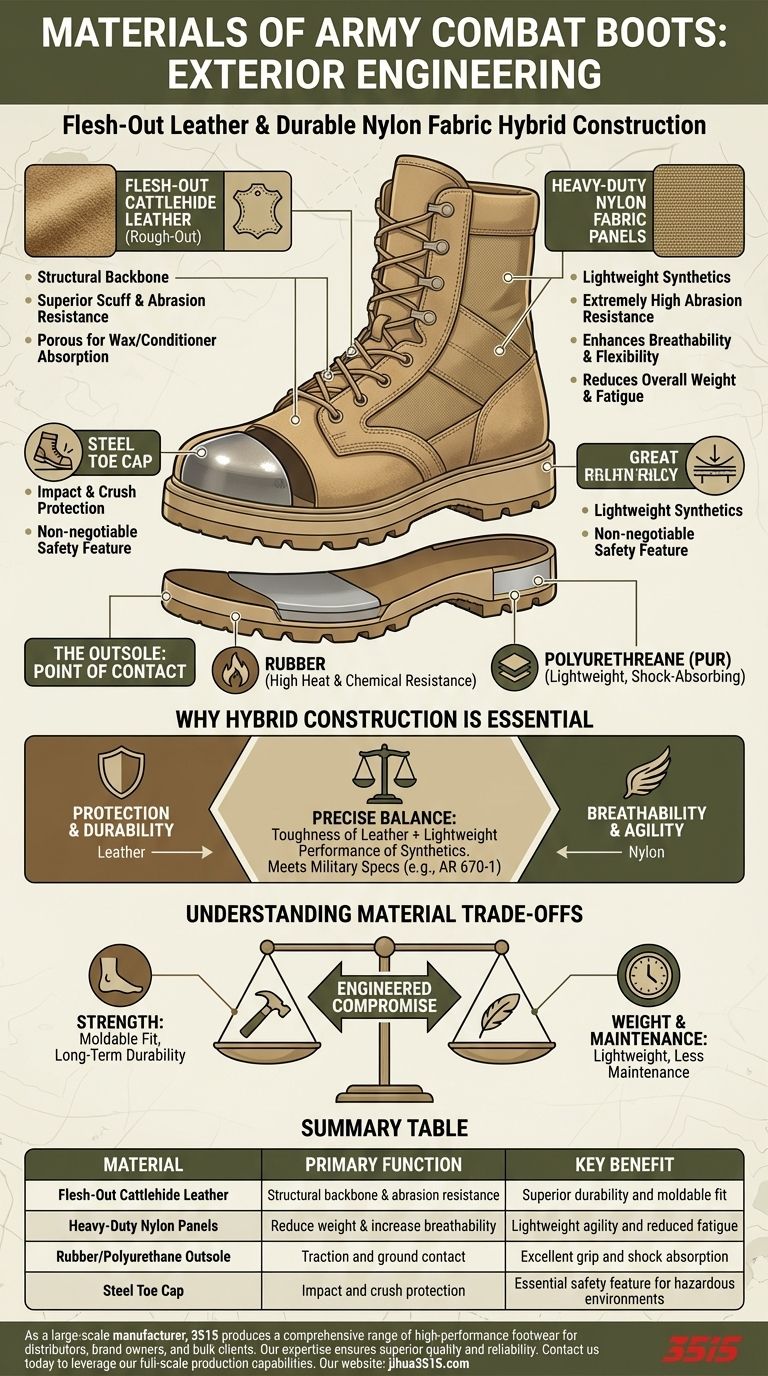

At its core, an army combat boot's exterior is constructed from a strategic combination of flesh-out cattlehide leather and durable nylon fabric. This hybrid approach is not accidental; it is an engineered solution designed to provide a precise balance of rugged protection, environmental adaptability, and wearer comfort required for performance in the most demanding conditions.

The central principle behind modern combat boot design is not finding a single perfect material, but rather combining the unique strengths of leather and synthetics. This creates a composite material system that maximizes durability while minimizing weight and fatigue.

The Engineering Behind the Exterior

To understand why these materials are chosen, we must break down the boot's exterior into its functional components. Each material serves a distinct and critical purpose.

Flesh-Out Cattlehide Leather: The Foundation of Durability

The primary material is flesh-out cattlehide leather, often referred to as rough-out leather. This forms the structural backbone of the boot.

Unlike smooth leather, the rough side faces out. This choice provides superior resistance to scuffs and abrasions. The leather itself is layered to be virtually impenetrable to sharp objects on the battlefield.

Crucially, this high-grade leather is porous. This allows it to effectively absorb waxes and conditioning agents, which is essential for maintaining water resistance and pliability across a wide range of weather conditions.

Nylon Fabric Panels: The Role of Synthetics

Integrated alongside the leather are panels of heavy-duty nylon. These synthetic sections are critical for modernizing the boot's performance.

Nylon offers extremely high resistance to abrasion while being significantly lighter than leather. Placing these panels in key areas reduces the boot's overall weight, which directly translates to less fatigue for the soldier over long distances.

These fabric panels also enhance the boot's flexibility and breathability, allowing heat and moisture to escape more effectively than an all-leather design would.

The Outsole: The Point of Contact

The outsole—the part that meets the ground—is typically made from rubber or a polyurethane (PUR) compound.

Rubber is favored for its exceptional resistance to high heat and chemicals, providing a stable and protective layer in hazardous environments.

Polyurethane is often used for its lighter weight and superior shock-absorbing properties, which helps reduce stress on the feet and legs during high-impact activities.

Protective Reinforcements: The Steel Toe

Many combat boots incorporate a steel toe cap as a non-negotiable safety feature. This element is integrated into the front of the boot to protect the foot from crushing and impact injuries, a common risk in military and industrial settings.

Why This Hybrid Construction is Essential

The deliberate combination of leather, nylon, and specialized rubber is a direct response to the multifaceted challenges a soldier faces.

Balancing Protection and Breathability

An all-leather boot would offer immense protection but would be heavy and retain heat. Conversely, an all-synthetic boot might be lighter but could lack the long-term, rugged durability of leather.

The hybrid design captures the best of both worlds: the proven toughness of leather and the lightweight, breathable performance of modern synthetics.

Meeting Strict Military Specifications

The materials and construction methods are not arbitrary. They are dictated by rigorous military regulations, such as AR 670-1, which codify the exact standards for durability, comfort, and protection that all official army footwear must meet.

Understanding the Material Trade-offs

No material choice is without compromise. Understanding these trade-offs reveals the expert engineering that goes into every pair of high-performance boots.

Leather's Strength and Weakness

The primary advantage of leather is its unmatched ability to mold to the wearer's foot over time while providing excellent long-term durability and breathability. Its main trade-off is the need for continuous maintenance and conditioning to preserve its protective qualities.

The Weight and Maintenance Factor

Every ounce matters when carried over miles. The integration of nylon is a direct acknowledgment that an all-leather boot would be too heavy for modern operational tempos. Synthetics also require significantly less maintenance than leather, a practical advantage in the field.

Specialized vs. General-Purpose Design

While the standard-issue boot is designed for versatility, specialized boots for jungle, desert, or cold-weather environments will alter the ratio of leather to synthetic fabric. A jungle boot may feature more nylon for drainage and airflow, while a cold-weather boot may use thicker, insulated leather.

Making the Right Choice for Your Goal

Applying these principles can help you select the right high-performance footwear for any demanding task.

- If your primary focus is maximum durability and weatherproofing: Look for footwear with a higher percentage of full-grain, treatable leather, and be prepared for the required maintenance.

- If your primary focus is lightweight agility and breathability: A hybrid model with significant nylon or other synthetic panels will be the superior choice, especially for hot climates or fast-paced activity.

- If your primary focus is industrial safety: Ensure the boot's construction includes a certified protective toe cap, regardless of the upper material.

Ultimately, the materials used in a combat boot are a direct investment in the user's performance, safety, and endurance.

Summary Table:

| Material | Primary Function | Key Benefit |

|---|---|---|

| Flesh-Out Cattlehide Leather | Structural backbone & abrasion resistance | Superior durability and moldable fit |

| Heavy-Duty Nylon Panels | Reduce weight & increase breathability | Lightweight agility and reduced fatigue |

| Rubber/Polyurethane Outsole | Traction and ground contact | Excellent grip and shock absorption |

| Steel Toe Cap | Impact and crush protection | Essential safety feature for hazardous environments |

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our expertise in engineering durable, comfortable, and mission-ready boots—using the optimal blend of leather, nylon, and safety features—ensures your customers get the superior quality and reliability they demand. Contact us today to discuss your specific footwear needs and leverage our full-scale production capabilities.

Visual Guide

Related Products

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

People Also Ask

- What was the primary motivation for developing this new jungle boot? Solving Critical Failures in Tropical Warfare

- What are some modern variations of desert boots with crepe soles? Style Meets Timeless Comfort

- How did the desert boot design become popular after World War II? A Tale of Style & Counter-Culture

- Does the army still use jump boots? From Battlefield to Ceremonial Symbol

- What is the origin of combat boots and their initial purpose? A History of Rugged Military Footwear

- Why are professional racing boots or off-road boots essential for high-risk riding? Maximize Your Skeletal Protection

- What are some examples of desert boots with leather uppers? Explore Versatile & Durable Styles

- What are the general specifications for Army boots? A Guide to AR 670-1 Compliant Footwear