The most common and effective material used for the soles of slip-resistant shoes is a high-grade or synthetic rubber compound. This material is chosen specifically for its ability to provide a strong grip and maintain superior traction, especially on wet, oily, or greasy surfaces where the risk of falling is highest.

The effectiveness of a slip-resistant shoe comes from a combination of two critical factors: the inherent friction of the sole's material and the mechanical design of its tread pattern, which work together to channel liquids and maximize surface contact.

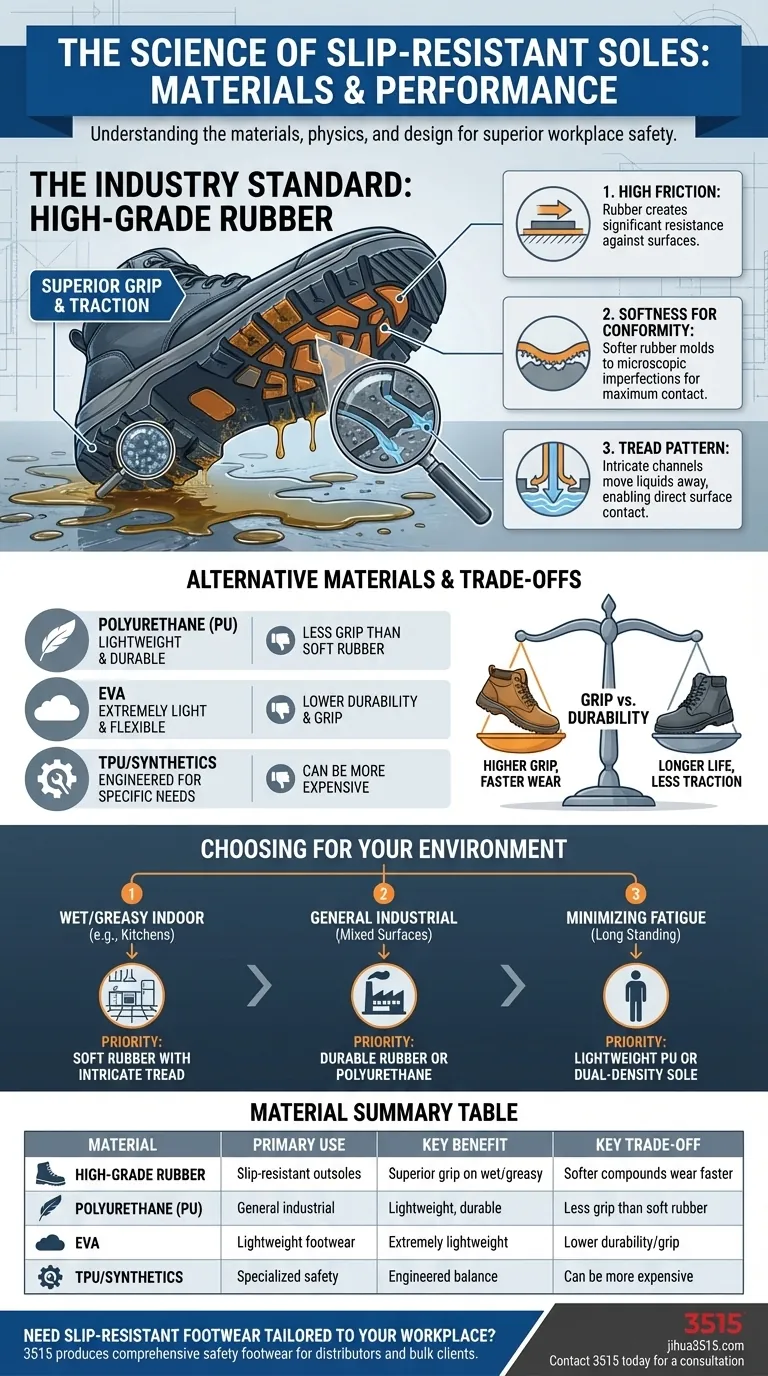

The Science Behind Superior Grip

To understand slip resistance, you must look beyond just the material and consider the physics at play. A shoe's ability to prevent a slip is determined by how its sole interacts with the floor surface at a microscopic level.

Why Rubber is the Industry Standard

High-grade rubber possesses a naturally high coefficient of friction. This means it creates significant resistance when moving against another surface, effectively "gripping" the floor. Furthermore, it is engineered for wear resistance and can withstand exposure to heat, acids, and alkalis common in industrial environments.

The Critical Role of Softness

Softer rubber compounds are generally more effective for slip resistance. They can better conform to the microscopic imperfections and texture of a floor, maximizing the total surface area in contact and creating a stronger hold.

More Than Material: The Tread Pattern

The physical design of the outsole is just as important as the material. An effective slip-resistant sole features an intricate tread pattern with small, open channels. This design works to quickly move water, oil, and other contaminants out from under the shoe, allowing the rubber to make direct, solid contact with the floor.

Exploring Alternative Sole Materials

While rubber is the benchmark, other advanced materials are also used, often chosen to balance grip with other factors like weight and durability.

Polyurethane (PU)

Polyurethane is a popular alternative known for being lightweight and durable. PU soles can offer good slip resistance and are often found in safety footwear where reducing fatigue is a priority.

EVA (Ethylene Vinyl Acetate)

EVA is an extremely lightweight and flexible foam-like material. While often used in the midsole for cushioning, it is sometimes used in outsoles for footwear where weight is the primary concern, though it may offer less grip and durability than rubber.

Synthetic Compounds and TPU

Thermoplastic Polyurethane (TPU) and other proprietary synthetic compounds are engineered to offer specific benefits. These materials can be formulated to provide a targeted balance of abrasion resistance, flexibility, and reliable grip.

Understanding the Trade-offs

Choosing the right material always involves balancing competing priorities. There is no single "best" material for every situation.

Grip vs. Durability

A critical trade-off exists between grip and longevity. The softest, grippiest rubber compounds that conform best to surfaces also tend to wear down more quickly. Harder compounds last longer but may offer less traction on slick surfaces.

Environment-Specific Needs

The ideal sole material depends entirely on the work environment. A sole designed for the greasy floors of a commercial kitchen requires different properties than one meant for an industrial site with exposure to chemicals or sharp debris.

Making the Right Choice for Your Environment

To select the most effective footwear, match the sole's characteristics to your specific workplace hazards.

- If your primary focus is wet or greasy indoor surfaces (e.g., kitchens, food processing): Prioritize a soft rubber sole with an intricate, liquid-channeling tread pattern.

- If your primary focus is general industrial use with mixed surfaces: Look for a durable rubber or polyurethane sole that offers a balance of reliable grip and high wear resistance.

- If your primary focus is minimizing fatigue from long periods of standing: Consider footwear with a lighter polyurethane or a dual-density sole that uses rubber only on the outsole for grip.

Ultimately, the safest choice is a shoe where the sole's material and design are perfectly engineered for the specific hazards you face every day.

Summary Table:

| Material | Primary Use | Key Benefit | Key Trade-off |

|---|---|---|---|

| High-Grade Rubber | Slip-resistant outsoles | Superior grip, especially on wet/greasy surfaces | Softer compounds wear faster |

| Polyurethane (PU) | General industrial safety shoes | Lightweight, durable, good all-around performance | May offer less grip than soft rubber |

| EVA (Ethylene Vinyl Acetate) | Lightweight footwear/midsoles | Extremely lightweight, flexible | Lower durability and grip compared to rubber |

| TPU/Synthetics | Specialized safety footwear | Engineered for specific balances of resistance and flexibility | Can be more expensive, less common |

Need Slip-Resistant Footwear Tailored to Your Workplace?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the optimal sole materials and tread patterns for your specific environment—whether it's a greasy kitchen, a wet industrial floor, or a demanding worksite.

We combine advanced materials science with durable construction to deliver footwear that protects your team and meets your exact specifications. Let's discuss your needs and create the perfect solution for your safety requirements.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health