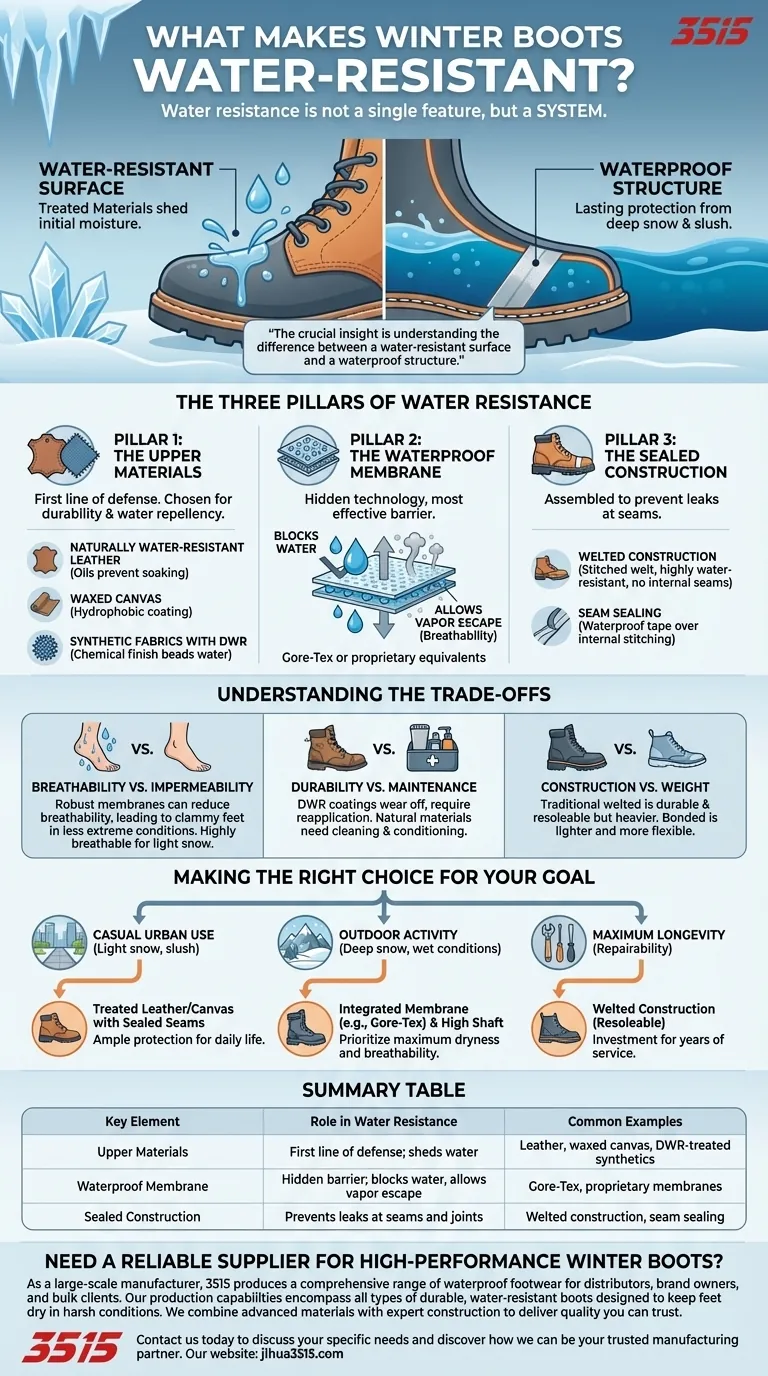

At its core, water resistance in winter boots is not a single feature but a system. It's achieved through a combination of specially treated upper materials, specific construction methods that seal out moisture, and often, an internal waterproof membrane that acts as the final barrier.

The crucial insight is understanding the difference between a water-resistant surface and a waterproof structure. While treated materials shed initial moisture, true, lasting protection from deep snow and slush depends on a boot's underlying construction and integrated waterproof membrane.

The Three Pillars of Water Resistance

To keep your feet dry, a winter boot relies on three distinct but complementary elements working in concert. Each one plays a critical role in blocking moisture from reaching your socks.

Pillar 1: The Upper Materials

The materials that form the visible exterior of the boot are the first line of defense. They are chosen for their natural durability and ability to repel water.

Common materials include naturally water-resistant leather, which contains oils that prevent water from soaking in, and waxed canvas, which uses a wax coating to make the fabric hydrophobic.

Many modern boots also feature synthetic fabrics treated with a Durable Water Repellent (DWR) coating. This chemical finish causes water to bead up and roll off the surface rather than penetrate the fibers.

Pillar 2: The Waterproof Membrane

This is the hidden technology that often separates a merely "water-resistant" boot from a truly "waterproof" one. It is the most effective barrier against moisture.

A waterproof membrane is a special layer, like Gore-Tex or a proprietary equivalent, built into the boot's lining. This membrane contains microscopic pores that are too small for water droplets to pass through from the outside.

Crucially, these pores are large enough to allow water vapor (sweat) to escape from the inside, providing essential breathability to keep your feet from getting damp from perspiration.

Pillar 3: The Sealed Construction

How a boot is assembled is just as important as the materials used. Water will always exploit the weakest point, which is typically the seams where different parts are joined.

High-quality boots often use welted construction. A strip of leather (the welt) is stitched to both the upper and the outsole, creating a highly water-resistant seal with no internal seams for water to seep through.

For other construction types, manufacturers rely on seam sealing, where a waterproof tape is applied over the stitching on the inside of the boot to block any potential leaks.

Understanding the Trade-offs

Choosing the right level of water resistance involves balancing protection with other important factors. No single boot is perfect for every situation.

Breathability vs. Impermeability

The most robust waterproof membranes can sometimes reduce a boot's overall breathability. In less extreme conditions, this can lead to sweaty, clammy feet, which can make you feel cold.

For casual wear in light snow, a highly breathable boot with a DWR coating may be more comfortable than one with a full waterproof membrane.

Durability vs. Maintenance

DWR coatings are not permanent. They wear off over time due to abrasion and dirt, requiring you to reapply a waterproofing spray to maintain performance.

Natural materials like leather also require regular care. They must be cleaned and conditioned to preserve their water-resistant properties and prevent the material from drying out and cracking.

Construction vs. Weight

Traditional, durable constructions like a Goodyear welt are exceptionally water-resistant and can be resoled, extending the boot's life. However, they are also significantly heavier and less flexible than more modern, bonded constructions.

Making the Right Choice for Your Goal

Your ideal winter boot depends entirely on how you plan to use it. Match the technology to your specific needs to ensure your feet stay warm and dry.

- If your primary focus is casual urban use (light snow, slushy sidewalks): A boot made from treated leather or waxed canvas with sealed seams will provide ample protection.

- If your primary focus is outdoor activity (deep snow, extended wet conditions): Prioritize a boot with an integrated waterproof membrane like Gore-Tex and a high shaft to prevent snow from entering from the top.

- If your primary focus is maximum longevity and repairability: Look for a boot with a welted construction that can be maintained for years and resoled when the tread wears down.

By understanding these core principles of materials, membranes, and construction, you can confidently select a boot that delivers the right level of protection for your winter.

Summary Table:

| Key Element | Role in Water Resistance | Common Examples |

|---|---|---|

| Upper Materials | First line of defense; sheds water | Leather, waxed canvas, DWR-treated synthetics |

| Waterproof Membrane | Hidden barrier; blocks water, allows vapor escape | Gore-Tex, proprietary membranes |

| Sealed Construction | Prevents leaks at seams and joints | Welted construction, seam sealing |

Need a reliable supplier for high-performance winter boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, water-resistant boots designed to keep feet dry in harsh conditions. We combine advanced materials with expert construction to deliver quality you can trust.

Contact us today to discuss your specific needs and discover how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments