At its core, the suitability of PVC (Polyvinyl Chloride) boots stems from a powerful combination of three key properties: they are exceptionally waterproof, highly durable, and resistant to a wide range of chemicals and other substances.

PVC boots provide a reliable and cost-effective barrier against common workplace hazards. Their value isn't in any single feature, but in the intersection of protection, resilience, and affordability that makes them a practical choice for many demanding jobs.

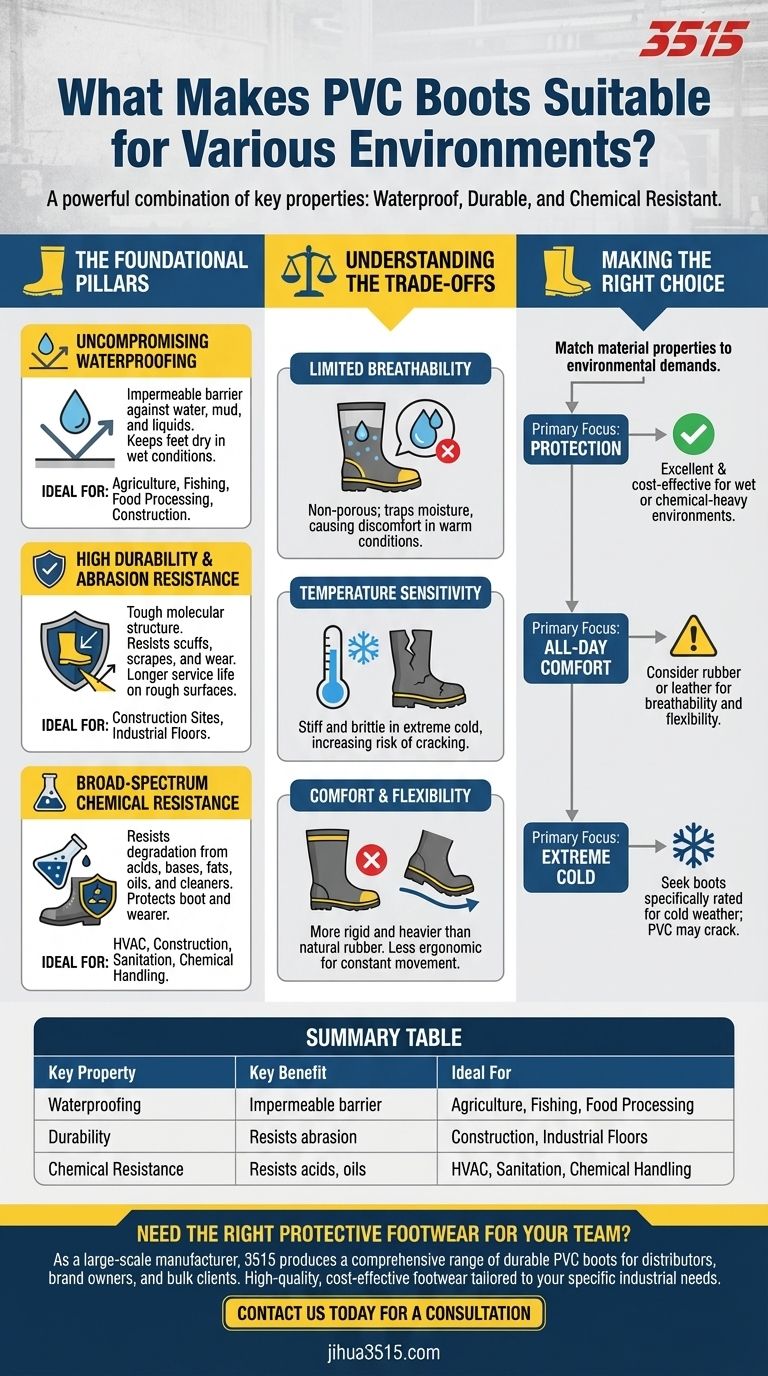

The Foundational Pillars of PVC Footwear

To understand if PVC is the right choice, you must first understand the specific advantages its material properties provide in a work environment. Each pillar of performance addresses a distinct set of hazards.

Uncompromising Waterproofing

PVC is a non-porous plastic. This simple fact means it creates an impermeable barrier against water, mud, and other liquids, keeping the wearer's feet completely dry in wet conditions.

This makes it an ideal material for industries like agriculture, fishing, food processing, and general construction work during inclement weather.

High Durability and Abrasion Resistance

The molecular structure of PVC makes it tough and resistant to scuffs, scrapes, and general wear-and-tear. This resilience is critical in environments with rough surfaces and demanding physical tasks.

Boots made from PVC can withstand the rigors of construction sites and industrial floors, ensuring a longer service life compared to less robust materials.

Broad-Spectrum Chemical Resistance

PVC is inherently resistant to degradation from many common acids, bases, fats, oils, and industrial cleaning agents. This protects both the boot and the wearer.

This resistance is crucial for safety in HVAC, construction, and sanitation work, where exposure to substances like adhesives, sealants, or harsh chemicals could otherwise cause chemical burns or degrade the footwear.

Understanding the Trade-offs of PVC

No material is perfect. Acknowledging the limitations of PVC is essential for making an informed decision and ensuring both safety and comfort.

Limited Breathability

The same non-porous quality that makes PVC waterproof also means it does not breathe. This can lead to significant sweat and moisture buildup inside the boot, causing discomfort during long shifts or in warm climates.

Temperature Sensitivity

In extremely cold conditions, standard PVC can become stiff and brittle. This loss of flexibility increases the risk of the material cracking, which compromises its protective barrier.

Comfort and Flexibility

Compared to materials like natural rubber, PVC is generally more rigid and can be heavier. While suitable for many tasks, it may not offer the same level of ergonomic comfort or flexibility for work that requires constant movement and agility.

Making the Right Choice for Your Application

Selecting the proper footwear requires matching the material's properties to the specific demands of your environment and tasks.

- If your primary focus is protection in wet or chemical-heavy environments: PVC offers an excellent and highly cost-effective solution.

- If your primary focus is all-day comfort in a physically active role: Consider the limited breathability and flexibility of PVC; a boot made of rubber or leather may be a better investment.

- If your primary focus is work in extremely cold temperatures: Standard PVC is likely unsuitable, and you should seek out boots specifically rated for cold weather.

Ultimately, choosing PVC boots is a strategic decision based on their proven ability to provide reliable barrier protection in many of the most common and challenging work environments.

Summary Table:

| Key Property | Key Benefit | Ideal For |

|---|---|---|

| Waterproofing | Impermeable barrier against liquids | Agriculture, Fishing, Food Processing |

| Durability | Resists abrasion and wear | Construction, Industrial Floors |

| Chemical Resistance | Resists acids, oils, and cleaning agents | HVAC, Sanitation, Chemical Handling |

| Trade-offs | Consideration | Alternative Needed When |

| Breathability | Low; can cause sweat buildup | All-day comfort in warm climates is a priority |

| Cold Weather | Can become stiff and brittle | Working in extremely cold temperatures |

| Flexibility | Generally more rigid than rubber | High agility and constant movement are required |

Need the right protective footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable PVC boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get high-quality, cost-effective footwear tailored to your specific industrial needs.

Contact us today for a consultation and discover how our PVC boots can enhance your workplace safety and efficiency.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- What types of Wellington boots are available for women? Find Your Perfect Fit for Work, Weather, and Style

- How does the tall height of PVC boots provide additional protection? Enhanced Coverage & Stability for Your Lower Leg

- Do wellies stretch over time? The Truth About Rubber Boot Fit & Comfort

- Why are Wellington boots considered a great footwear choice? Unmatched Waterproof Protection for Tough Conditions

- How does the tall height of PVC boots provide better protection? Extended Coverage for Superior Safety

- How did Wellington boots evolve during World War I? From Aristocratic Fashion to Military Necessity

- Why might someone choose PVC half-boots? For Unbeatable Waterproof Protection & Everyday Convenience

- How can wellies be useful during snowy weather? A Guide to Staying Dry and Safe