The durability of military boots comes from a system of deliberate choices, not a single feature. It is the fusion of robust, proven materials like full-grain leather and high-denier nylon with superior construction methods, such as reinforced, multi-row stitching and soles that are both glued and stitched to the upper. These elements work together to create footwear that can withstand extreme stress and harsh environments.

The true measure of a boot’s durability is not just the quality of its materials, but the integrity of its construction. A boot built with stitched-down soles and reinforced stress points will outlast a boot made of identical materials that are simply glued together.

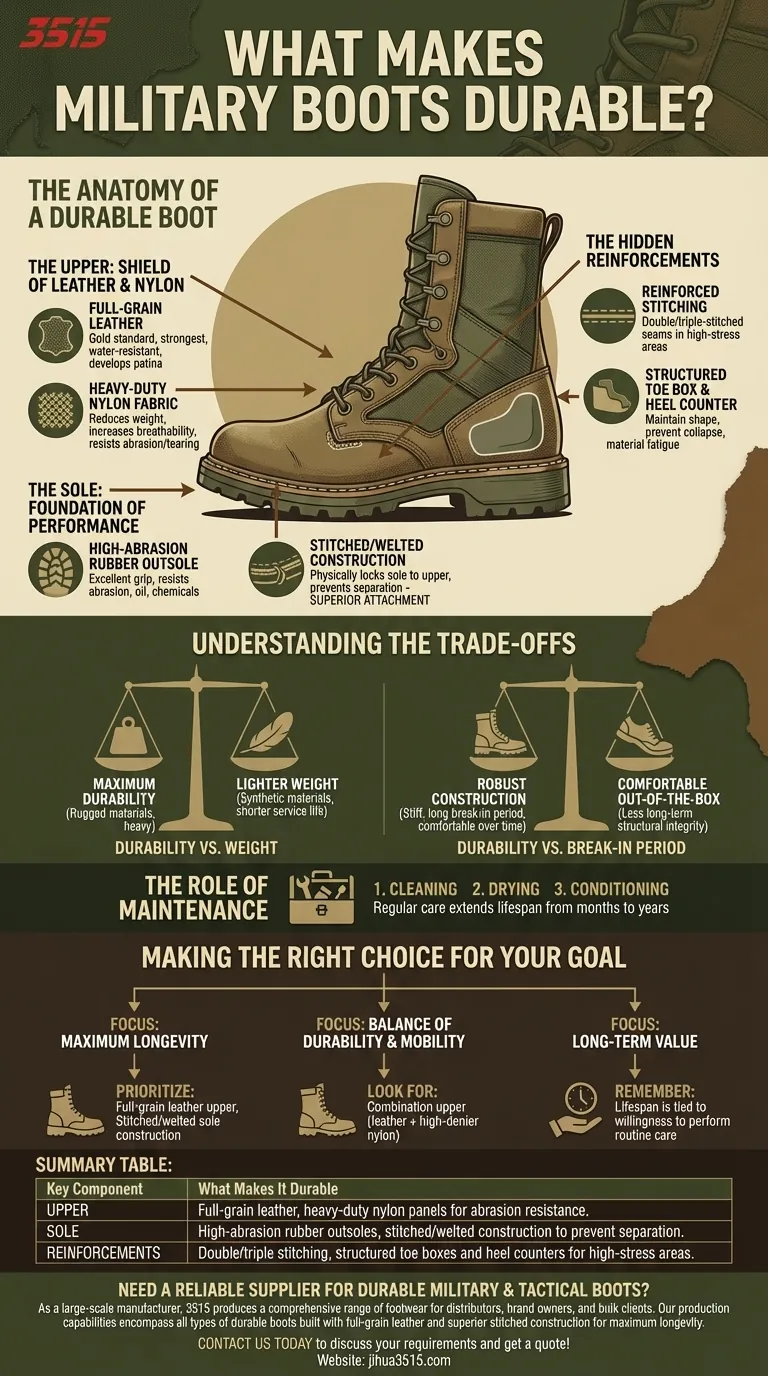

The Anatomy of a Durable Boot

To understand durability, we must look at the key components of the boot and the specific choices that fortify them against failure.

The Upper: A Shield of Leather and Nylon

The "upper" is the main body of the boot that covers your foot. Its durability depends on using materials that resist abrasion, tearing, and moisture.

Full-grain leather is the gold standard. It is the strongest and most water-resistant type of leather, taken from the top layer of the hide, and it develops a unique patina over time instead of wearing out.

Heavy-duty nylon fabric is often integrated into leather uppers. This reduces weight and increases breathability without significantly compromising strength in key flex areas.

The Sole: The Foundation of Performance

A boot's sole assembly is a frequent point of failure. The most durable boots use high-quality materials and, more importantly, a superior attachment method.

Rubber is the material of choice for outsoles due to its excellent grip and high resistance to abrasion, oil, and chemicals.

The most critical feature is how the sole is attached. While many boots use strong adhesives, the most durable military and work boots add stitching—often a "welt"—that physically locks the sole to the upper, making separation nearly impossible.

The Hidden Reinforcements

Smaller details reveal a manufacturer's commitment to durability. These are features designed to handle consistent, high-stress use.

Reinforced stitching is crucial. Look for double or even triple-stitched seams in areas that bear the most strain, like where the heel connects to the main body.

Structured toe boxes and heel counters provide protection and also help the boot maintain its shape over years of use, preventing collapse and material fatigue.

Understanding the Trade-offs

Choosing a durable boot involves balancing competing factors. Maximum durability often comes with compromises in other areas.

Durability vs. Weight

The most rugged materials, like thick full-grain leather and dense rubber soles, are heavy. Lighter boots using more synthetic materials may be more comfortable for rapid movement but will almost always have a shorter service life.

Durability vs. Break-in Period

Stiff, thick leather and robustly constructed boots require a significant break-in period. They mold to your feet over time but can be uncomfortable at first. More flexible boots are comfortable out of the box but often at the cost of long-term structural integrity.

The Role of Maintenance

No boot is indestructible. Durability is a partnership between the manufacturer and the owner. Regular cleaning, drying, and conditioning of the leather prevents it from cracking and breaking down, significantly extending the boot's functional lifespan from months to years.

Making the Right Choice for Your Goal

Look beyond the brand name and marketing claims to inspect the core features that define a boot's ability to last.

- If your primary focus is maximum longevity: Prioritize a boot with a full-grain leather upper and a stitched or welted sole construction.

- If your primary focus is a balance of durability and mobility: Look for a combination upper made of leather and high-denier nylon panels.

- If your primary focus is long-term value: Remember that a boot's lifespan is directly tied to your willingness to perform routine care and maintenance.

Understanding these principles of material science and construction empowers you to identify a truly durable boot designed for years of service.

Summary Table:

| Key Component | What Makes It Durable |

|---|---|

| Upper | Full-grain leather, heavy-duty nylon panels for abrasion resistance. |

| Sole | High-abrasion rubber outsoles, stitched/welted construction to prevent separation. |

| Reinforcements | Double/triple stitching, structured toe boxes and heel counters for high-stress areas. |

Need a reliable supplier for durable military and tactical boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable boots built with full-grain leather and superior stitched construction for maximum longevity.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What is the proper method to clean military boots? A Step-by-Step Guide to Maximize Longevity

- What are the essential steps for cleaning military boots? A Complete Guide to Preserve Your Gear

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style