At its core, crust leather is unique because it is a dyed but intentionally unfinished material. Unlike fully finished leathers that are sealed at the tannery, crust leather is delivered as a "blank canvas," allowing shoe artisans to apply dyes, creams, and waxes by hand to create a completely custom and one-of-a-kind patina.

The essential difference with crust leather is a shift in philosophy: from the uniform perfection of mass production to the unique character of artisanal craftsmanship. It is chosen not just for what it is, but for what it can become.

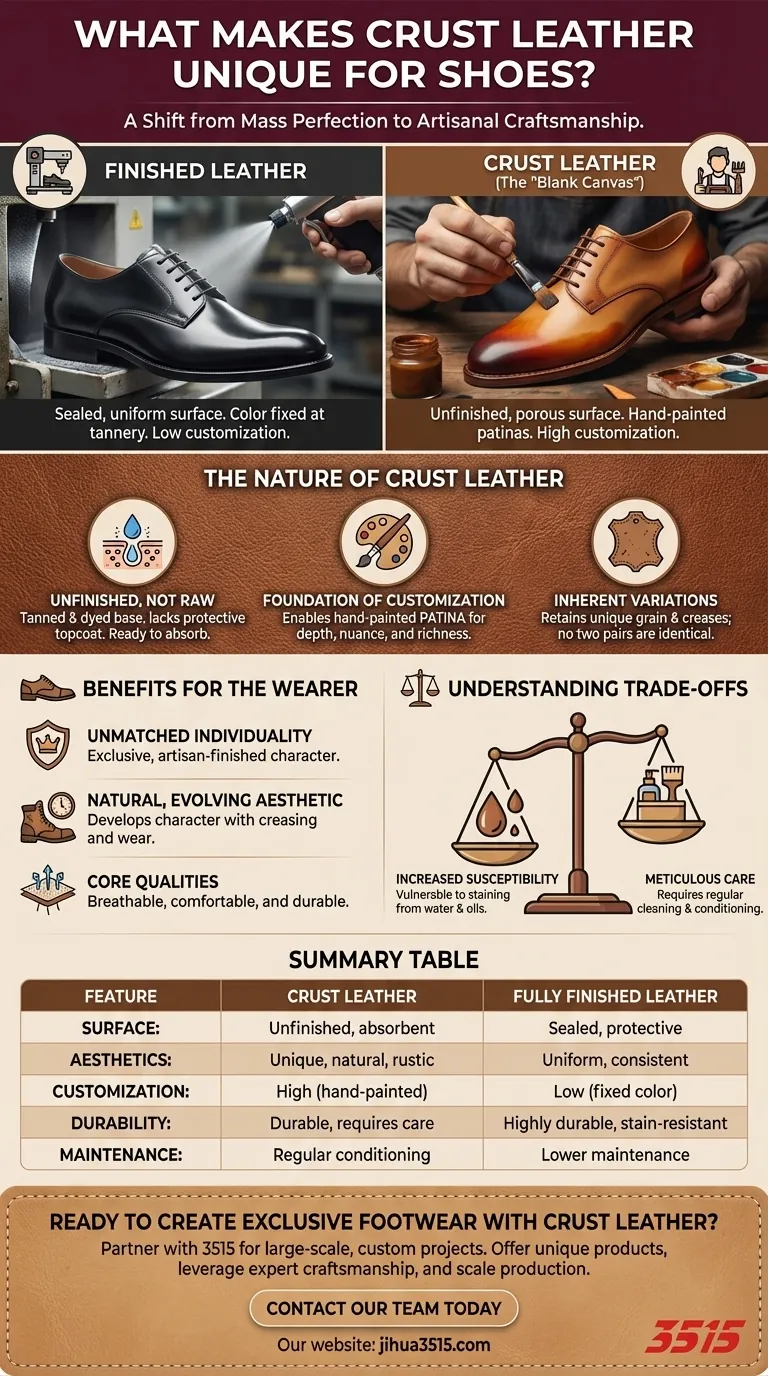

The Nature of Crust Leather: An Unfinished Canvas

To understand crust leather, you must first understand the concept of "finishing." The final stages of leather production typically involve applying pigments and protective topcoats to create a uniform, durable surface. Crust leather deliberately skips this final, sealing step.

What "Unfinished" Truly Means

"Unfinished" does not mean raw. The leather has been fully tanned and dyed to give it a base color.

However, it lacks the final, impenetrable protective topcoat. This leaves the leather's natural pores open and its surface ready to absorb color and conditioning.

The Foundation of Customization

This absorbent, unfinished state is precisely what makes crust leather so valued in high-end shoemaking.

It enables artisans to hand-paint the leather, a process known as creating a patina. This allows for a depth, nuance, and richness of color that is impossible to achieve with industrial, spray-on finishes.

Inherent Textural Variations

Because it is not coated and corrected, each piece of crust leather retains its unique natural grain and small imperfections.

These subtle creases and texture variations are not defects; they are hallmarks of a natural material that ensure no two pairs of shoes made from it are ever identical.

The Tangible Benefits for the Wearer

Choosing shoes made from crust leather provides distinct advantages that go beyond the material itself, focusing on aesthetics and the ownership experience.

Unmatched Individuality

The most significant benefit is exclusivity. The hand-finishing process guarantees that your pair of shoes has a unique color and character, a direct result of the artisan's touch.

A Natural, Evolving Aesthetic

Crust leather offers a natural and rustic look. Like all high-quality natural leathers, it develops character over time, with creasing and wear adding to its story and beauty.

Core Leather Qualities

Beneath the custom finish, crust leather retains the essential properties of premium leather: it is breathable, comfortable, and, with proper care, highly durable. The open-pore structure enhances its ability to absorb moisture and conform to the wearer's foot.

Understanding the Trade-offs

The very features that make crust leather desirable also create its primary vulnerabilities. Objectivity requires acknowledging these trade-offs.

Increased Susceptibility

The lack of a sealed topcoat means crust leather is more vulnerable to staining from water, oils, and other substances.

This connects to a general trait of some natural leathers, which can have poor resistance to corrosive or harsh elements compared to heavily treated alternatives.

The Need for Meticulous Care

Crust leather footwear demands more diligent care than its finished counterparts.

Regular cleaning and conditioning are not just recommended; they are essential to nourish the leather, maintain its custom finish, and protect it from drying out or staining.

Making the Right Choice for Your Footwear

Your decision should be based on your priorities for aesthetics, maintenance, and use case.

- If your primary focus is artisanal character and personalization: Crust leather is the definitive choice for a truly unique shoe with unparalleled depth of color.

- If your primary focus is maximum durability with minimal maintenance: A high-quality, fully-finished calfskin may be a more practical choice for a daily-wear shoe in unpredictable conditions.

Ultimately, choosing crust leather is an investment in individuality and the craft of traditional shoemaking.

Summary Table:

| Feature | Crust Leather | Fully Finished Leather |

|---|---|---|

| Surface | Unfinished, porous, absorbent | Sealed with protective topcoat |

| Aesthetics | Unique, natural grain, rustic look | Uniform, consistent color |

| Customization | High (hand-painted patinas possible) | Low (color is fixed at the tannery) |

| Durability | Durable but requires more care | Highly durable and stain-resistant |

| Maintenance | Requires regular conditioning | Lower maintenance |

Ready to Create Exclusive Footwear with Crust Leather?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including custom projects with premium materials like crust leather.

Partner with us to:

- Offer Unique Products: Stand out in the market with shoes featuring one-of-a-kind, artisanal patinas.

- Leverage Expert Craftsmanship: Utilize our manufacturing expertise to bring your custom designs to life.

- Scale Your Production: Benefit from our large-scale capabilities to meet any order volume efficiently.

Let's discuss how we can help you develop a distinctive footwear line. Contact our team today for a consultation.

Visual Guide

Related Products

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What are the characteristics of suede leather cowboy boots? Discover Rugged Comfort & Style

- What roles do customized support shoes and flexible straps play in exoskeletons? Enhancing Torque & Safety

- What are the advantages and disadvantages of Birko-Flor? A Practical Guide to Choosing Your Footwear Material

- How does the implementation of AVs support green warehousing in footwear logistics? Efficiency Meets Sustainability

- Why is the reduction of plastic packaging significant in footwear? Drive Efficiency with Sustainable Logistics

- What are the risks of wearing heavy footwear? The Hidden Dangers to Your Body's Foundation

- Why is skin pretreatment necessary before motion capture and EMG? Ensure Data Integrity with Low Impedance

- Why are slippers practical for everyday wear? Effortless Comfort & Convenience for Modern Life