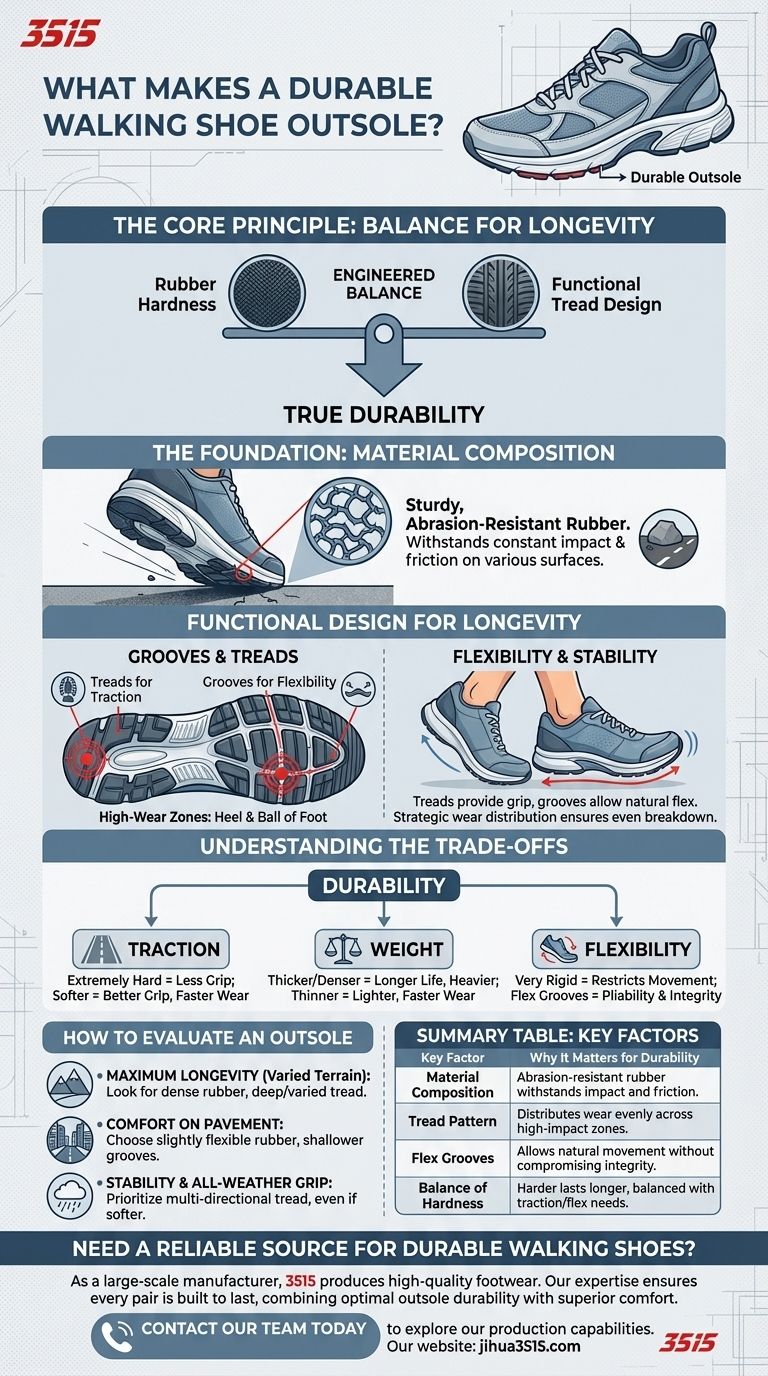

A durable walking shoe outsole is primarily defined by its material composition—specifically, a sturdy, abrasion-resistant rubber. This material is engineered to withstand the constant impact and friction of various walking surfaces while its tread pattern provides essential traction and stability.

The true durability of a walking shoe's outsole lies in a carefully engineered balance between the hardness of the rubber compound and a functional tread design that distributes wear effectively without compromising flexibility.

The Foundation: Material Composition

The single most important factor in outsole durability is the material it's made from. This component makes direct contact with the ground and absorbs the majority of wear and tear.

The Critical Role of Rubber

The outsole is almost universally made from rubber due to its unique combination of toughness and resilience. It is specifically formulated to resist being worn away by abrasive surfaces like pavement and trails.

Why It Withstands Damage

This sturdy rubber is designed to handle repeated impact across different terrains. It provides the core structure that prevents the bottom of the shoe from breaking down prematurely.

Functional Design for Longevity

Beyond the material itself, the physical design of the outsole plays a crucial role in how long it lasts. The pattern of grooves and treads is engineered for more than just grip.

The Purpose of Grooves and Treads

Treads are the protruding parts of the outsole that make contact with the ground, providing traction. Grooves are the channels between them that allow the shoe to flex and bend with your foot's natural movement.

How Design Dictates Wear

A well-designed outsole features a tread pattern that strategically places more durable material in high-wear zones, like the heel and the ball of the foot. This ensures the shoe wears down more evenly over time.

Maintaining Flexibility and Stability

While the rubber must be tough, the outsole cannot be a rigid plank. The grooves allow for necessary flexibility, ensuring a comfortable and natural walking gait, which in turn contributes to the shoe's overall stability.

Understanding the Trade-offs

Choosing an outsole is never about a single feature. Durability must always be balanced against other critical performance factors.

Durability vs. Traction

Extremely hard rubber compounds are highly durable but can sometimes offer less grip on smooth, wet surfaces. Softer, "stickier" rubbers provide excellent traction but tend to wear out much faster.

Durability vs. Weight

Thicker, denser rubber outsoles will almost always last longer. However, this adds significant weight to the shoe, which can lead to foot fatigue on longer walks.

Durability vs. Flexibility

A very rigid and durable outsole can restrict the natural movement of your foot. The best designs use flex grooves to provide pliability in key areas without sacrificing the structural integrity of the high-wear zones.

How to Evaluate an Outsole

When selecting your next pair of walking shoes, use these guidelines to assess the outsole based on your needs.

- If your primary focus is maximum longevity for varied terrain: Look for a dense rubber outsole with a relatively deep and varied tread pattern.

- If your primary focus is comfort for walking on pavement: A slightly more flexible rubber with shallower grooves will likely provide sufficient durability and better comfort.

- If your primary focus is stability and all-weather grip: Prioritize an outsole with a clear, multi-directional tread pattern, even if the rubber feels slightly softer to the touch.

Understanding these core principles empowers you to look beyond marketing claims and choose a shoe built to last.

Summary Table:

| Key Factor | Why It Matters for Durability |

|---|---|

| Material Composition | Abrasion-resistant rubber withstands impact and friction from various surfaces. |

| Tread Pattern | Distributes wear evenly across high-impact zones like the heel and ball of the foot. |

| Flex Grooves | Allows natural foot movement without compromising the outsole's structural integrity. |

| Balance of Hardness | Harder rubber lasts longer, but must be balanced with traction and flexibility needs. |

Need a reliable source for durable walking shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our expertise in material science and production engineering ensures every pair is built to last, combining optimal outsole durability with superior comfort.

Let's discuss your specific needs. Contact our team today to explore our production capabilities and find the perfect footwear solution for your market.

Visual Guide

Related Products

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

People Also Ask

- How should trousers be paired with lace-up boots? Master the Perfect Break and Cuff

- Can you sleep without walking boots after ankle surgery? Protect Your Healing Ankle for a Faster Recovery

- How do waterproof materials benefit winter boots? Keep Feet Warm and Dry in Harsh Conditions

- What are the characteristics of walking boots? Essential Features for Rugged Terrain & Heavy Loads

- What factors should be considered when choosing men's snow boots? Find the Perfect Boot for Your Winter Needs

- Why are ROM walking boots used for Achilles tendon injuries? For a Faster, Stronger Recovery

- What makes walking shoes suitable for individuals with diabetes? Essential Features for Foot Protection

- What materials are commonly used in protective motorcycle boots? The Ultimate Guide to Rider Safety