To significantly prolong the usability of your winter boots, you must adopt a consistent routine of cleaning, proper drying, and proactive waterproofing. While regular inspection for cracks or tears is vital, it's the preventative care that stops that damage from occurring in the first place, pushing back the need for replacement.

The core principle of winter boot maintenance is moisture management. Protecting your boots from external moisture (snow, salt, slush) and allowing them to recover from internal moisture (sweat) is the single most effective way to prevent material degradation and extend their functional lifespan.

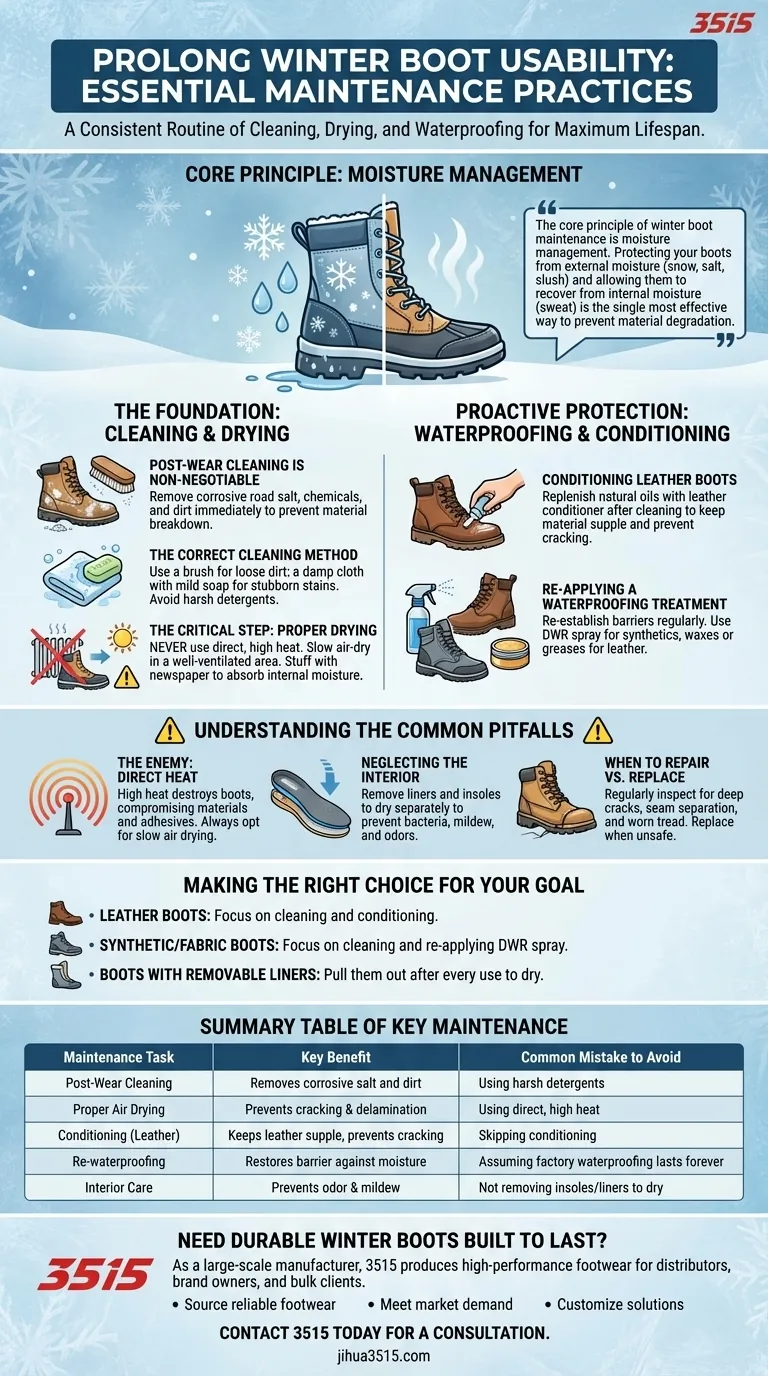

The Foundation: Cleaning and Drying

Proper cleaning and drying after use is not just about appearance; it's the first line of defense against premature wear. Salt, chemicals, and dirt are abrasive and will actively break down leather and synthetic fabrics over time.

Why Post-Wear Cleaning is Non-Negotiable

Road salt and de-icing chemicals are corrosive. If left to sit, they draw moisture out of leather, causing it to dry, stiffen, and eventually crack. On synthetic materials, this buildup can abrade the fabric and compromise waterproof coatings.

The Correct Cleaning Method

For most boots, the process is simple. Use a brush to remove loose dirt and debris. For stubborn salt stains or mud, use a damp cloth with a mild solution of soap and water. Avoid harsh detergents that can strip protective oils and coatings.

The Critical Step: Proper Drying

This is where most boots are inadvertently ruined. Never use direct, high heat (like a radiator, fireplace, or high-setting boot dryer) to dry your boots. This intense heat causes leather to crack, synthetic fabrics to become brittle, and adhesives used in the sole to fail, leading to delamination.

The best method is slow air-drying in a well-ventilated area away from direct sun. You can speed the process by removing the insoles and stuffing the boots with newspaper, which helps absorb internal moisture.

Proactive Protection: Waterproofing and Conditioning

Factory waterproofing wears off with use. You must proactively re-establish this barrier to keep your feet dry and protect the boot's structural materials.

Conditioning Leather Boots

Leather is a skin and requires moisture to stay flexible. After cleaning, and once fully dry, apply a leather conditioner to replenish its natural oils. This prevents cracking and keeps the material supple, extending its life significantly.

Re-applying a Waterproofing Treatment

For both leather and synthetic boots, re-applying a waterproofing treatment is key. For synthetics, this is typically a spray-on Durable Water Repellent (DWR) coating. For leather, waxes or greases provide a more robust and nourishing barrier against moisture.

Understanding the Common Pitfalls

Avoiding common mistakes is just as important as performing the right maintenance tasks. These errors can drastically shorten the lifespan of even the most durable boots.

The Enemy: Direct Heat

It bears repeating: high heat is the fastest way to destroy a pair of winter boots. It compromises every single component, from the outer material to the glue holding the sole. Always opt for slow, gentle air drying.

Neglecting the Interior

The inside of the boot matters, too. If your boots have removable liners or insoles, take them out to dry separately after each use. This prevents the buildup of bacteria and mildew, which create odors and can degrade the interior materials over time.

When to Repair vs. Replace

Consistent maintenance will dramatically extend a boot's life, but no boot lasts forever. Regularly inspect for critical failure points: deep cracks in the sole, seams separating from the upper, or tread that is worn smooth. These issues compromise waterproofing and traction, making the boot unsafe and ready for replacement.

Making the Right Choice for Your Goal

Your maintenance routine should be tailored slightly based on your boot's primary material.

- If your primary boots are leather: Focus on a two-step process of cleaning and conditioning to keep the material nourished and flexible.

- If your primary boots are synthetic/fabric: Concentrate on keeping them clean and regularly re-applying a DWR spray to maintain the surface water repellency.

- If your boots have removable liners: Make it a habit to pull them out after every single use to allow the entire system to dry thoroughly.

By treating your winter boots as a piece of essential equipment, you ensure they will protect you for many seasons to come.

Summary Table:

| Maintenance Task | Key Benefit | Common Mistake to Avoid |

|---|---|---|

| Post-Wear Cleaning | Removes corrosive salt and dirt | Using harsh detergents that strip protective coatings |

| Proper Air Drying | Prevents material cracking and sole delamination | Using direct, high heat from radiators or high-heat dryers |

| Conditioning (Leather) | Keeps leather supple and prevents cracking | Skipping conditioning after cleaning and drying |

| Re-waterproofing | Restores barrier against moisture and slush | Assuming factory waterproofing lasts the boot's lifetime |

| Interior Care | Prevents odor and material degradation from mildew | Not removing insoles/liners to dry separately |

Need Durable Winter Boots Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable winter boots designed to withstand harsh conditions and proper maintenance routines.

We help you:

- Source reliable footwear with superior materials and construction that respond well to care.

- Meet market demand with boots built for longevity, reducing replacement cycles for your customers.

- Customize solutions for your specific climate and performance requirements.

Let's discuss how our manufacturing expertise can provide the durable winter footwear your business needs.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the benefits of snow boots made from a combination of materials? Superior Winter Performance

- What is the difference between Chukka boots and Desert Boots? A Guide to Choosing the Right Ankle Boot

- What role do professional ankle fixation braces or walking boots play in the postoperative recovery for Achilles tendon detachment cases of less than 50 percent?

- What materials are commonly used in snow boots? A Guide to Warmth, Waterproofing & Traction

- How does anterior and posterior position data contribute to balance evaluation? Measuring the Support Line for Stability

- How can men's winter boots be maintained? Proactive Care to Extend Their Lifespan

- What is the difference between neutral and stability shoes? Find the Perfect Fit for Your Gait

- Why is support important in winter footwear? Prevent Injury & Boost Stability