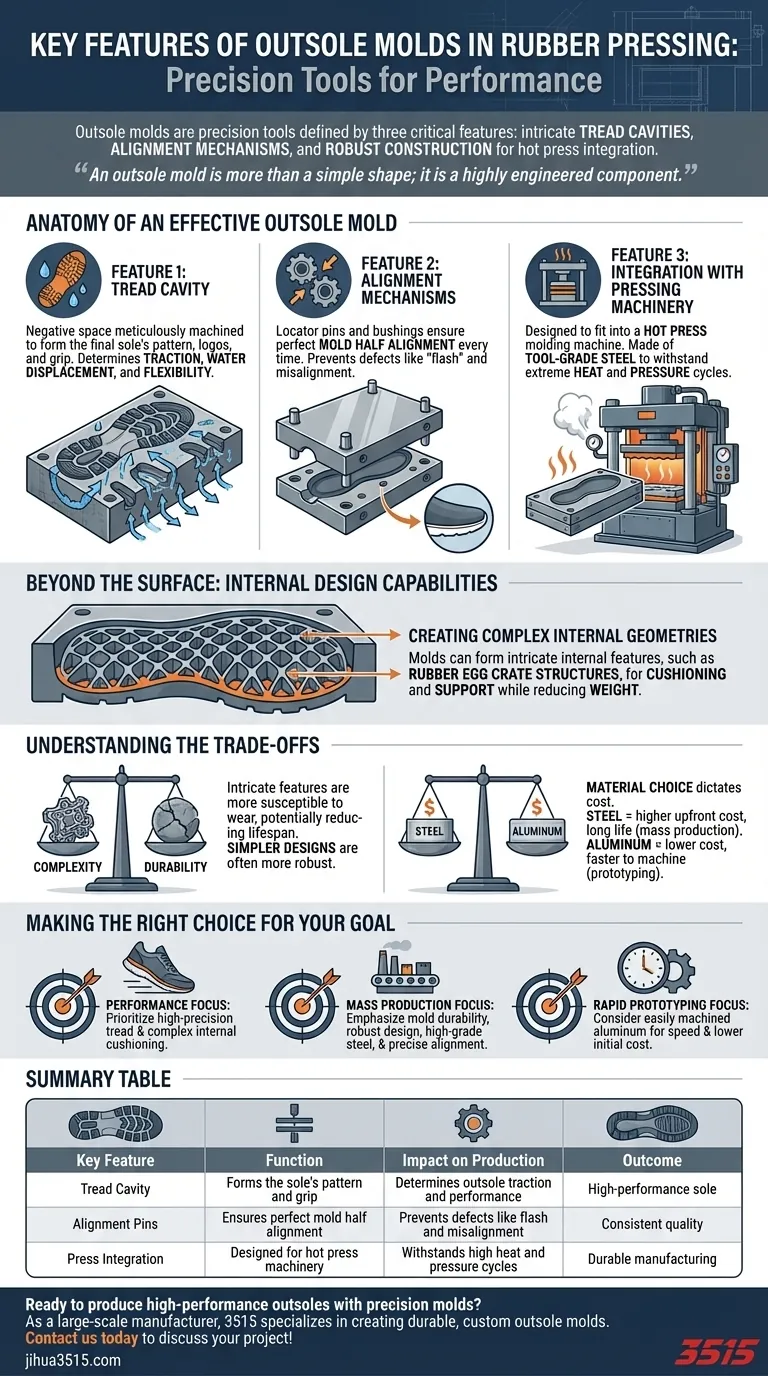

At their core, outsole molds for rubber pressing are precision tools defined by three critical features. These are the intricate tread cavities that form the sole's pattern, the locator pins that ensure perfect alignment between mold halves, and a robust construction designed to integrate with hot press machinery and withstand immense heat and pressure.

An outsole mold is more than a simple shape; it is a highly engineered component that directly translates a digital design into a functional, three-dimensional product. Its features are a direct reflection of the competing demands for performance, durability, and manufacturing efficiency.

The Anatomy of an Effective Outsole Mold

To understand the final product, you must first understand the tool that creates it. The design of an outsole mold is a direct expression of its intended function within a high-temperature, high-pressure manufacturing environment.

Feature 1: The Tread Cavity

The most apparent feature of the mold is the negative space that forms the tread. This cavity is meticulously machined to create the final outsole's texture, logos, and grip patterns.

The precision of these details directly determines the outsole's functional characteristics, such as traction, water displacement, and flexibility.

Feature 2: Alignment Mechanisms

Outsole molds are typically multi-part tools, often consisting of a top and bottom half. Locator pins and corresponding bushings are critical for ensuring these halves align perfectly every single time.

Without precise alignment, the process would yield defective parts with issues like "flash"—where excess rubber squeezes out—or an inconsistent, off-center tread pattern.

Feature 3: Integration with Pressing Machinery

An outsole mold does not exist in isolation. It is designed to fit precisely into a hot press molding machine.

This requires the mold to be made of materials, typically tool-grade steel, that can withstand repeated cycles of extreme heat and pressure without deforming. Its external dimensions must also match the specifications of the press platens for secure mounting.

Beyond the Surface: Internal Design Capabilities

The most sophisticated molds do more than just shape the bottom of a shoe. They are engineered to create complex internal structures that are vital to the footwear's performance and comfort.

Creating Complex Internal Geometries

Molds can be designed to form intricate internal features, such as a rubber egg crate structure. This type of design is a classic engineering solution for providing cushioning and support.

By creating hollow or patterned internal voids, designers can significantly reduce the outsole's weight and material consumption without sacrificing structural integrity.

Understanding the Trade-offs

Designing and using outsole molds involves balancing competing priorities. Understanding these trade-offs is crucial for efficient and effective manufacturing.

Balancing Complexity and Durability

Highly intricate tread patterns or internal structures can require delicate features within the mold. These features may be more susceptible to wear and tear, potentially reducing the overall lifespan of the tool.

A simpler design is often more robust and may last for more production cycles, but at the cost of performance or aesthetic detail.

Material Choice and Tooling Cost

The choice of material for the mold itself—such as hardened steel versus aluminum—is a primary factor in its cost. Steel molds are more expensive upfront but offer a much longer operational life, making them suitable for high-volume production.

Aluminum molds are cheaper and faster to machine but wear out more quickly, making them better suited for prototyping or limited production runs.

Making the Right Choice for Your Goal

Your specific objective should dictate your approach to mold design and material selection.

- If your primary focus is performance: Prioritize molds with high-precision tread details and the capability for complex internal cushioning structures.

- If your primary focus is cost-effective mass production: Emphasize mold durability through robust design and high-grade steel, along with features that minimize defects, such as precise alignment systems.

- If your primary focus is rapid prototyping: Consider molds made from more easily machined materials like aluminum, accepting a shorter operational lifespan in exchange for speed and lower initial cost.

Understanding these core features empowers you to make informed decisions, ensuring the final outsole performs exactly as designed.

Summary Table:

| Key Feature | Function | Impact on Production |

|---|---|---|

| Tread Cavity | Forms the sole's pattern and grip | Determines outsole traction and performance |

| Alignment Pins | Ensures perfect mold half alignment | Prevents defects like flash and misalignment |

| Press Integration | Designed for hot press machinery | Withstands high heat and pressure cycles |

Ready to produce high-performance outsoles with precision molds? As a large-scale manufacturer, 3515 specializes in creating durable, custom outsole molds for distributors, brand owners, and bulk clients. Our expertise ensures your footwear meets exact design and performance standards. Contact us today to discuss your project and benefit from our comprehensive footwear production capabilities!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

People Also Ask

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability