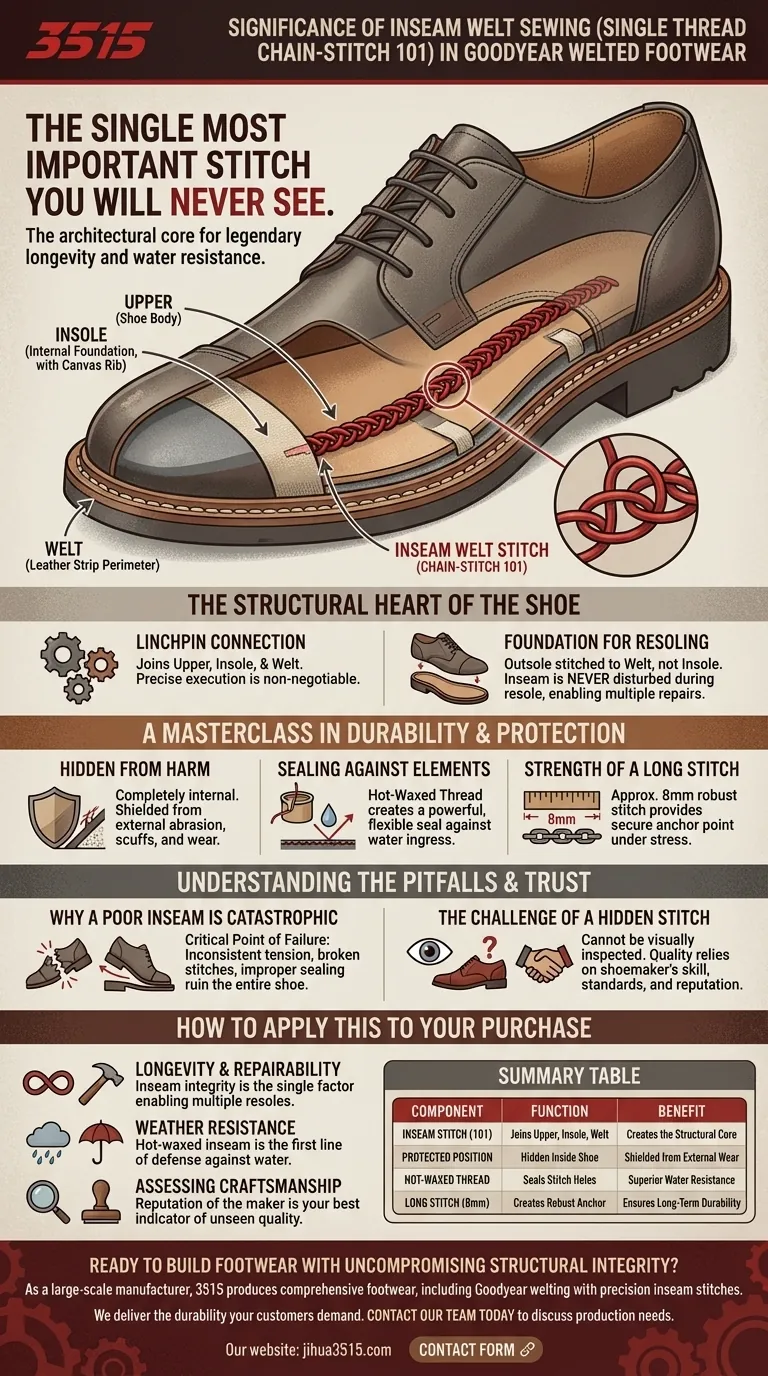

The single most important stitch in a Goodyear welted shoe is the one you will never see. The inseam welt stitch, specifically a single-thread chain-stitch (type 101), is the hidden structural foundation that joins the shoe's upper, insole, and welt. This seam creates the durable and water-resistant platform upon which the entire construction depends for its legendary longevity.

The inseam welt stitch is not just a seam; it is the architectural core of Goodyear welted footwear. Its significance lies in its hidden, protected position, which ensures the shoe's structural integrity and its ability to be repeatedly resoled—the very qualities that define this construction method.

The Structural Heart of the Shoe

The inseam is the first major stitching operation in the Goodyear welting process, and it acts as the lynchpin for everything that follows. Its precise execution is non-negotiable for a quality shoe.

What the Inseam Connects

This critical stitch meticulously joins three key components: the upper (the main body of the shoe), a canvas rib on the insole (the shoe's internal foundation), and the welt (a separate strip of leather that runs around the perimeter).

The Foundation for Resoling

Crucially, the outsole is later stitched directly to the welt, not through the insole. This means the inseam is never disturbed during a resole. Its integrity is what allows a cobbler to remove the old outsole and stitch on a new one multiple times without compromising the shoe's core structure.

A Masterclass in Durability and Protection

The design of the inseam stitch is a deliberate engineering choice focused entirely on longevity and performance, prioritizing function over aesthetics.

Hidden from Harm

Because the stitch is completely internal, it is shielded from all external abrasion, scuffs, and wear. Unlike an outsole stitch that grinds against the pavement, the inseam remains protected for the life of the shoe.

Sealing Against the Elements

The thread used for the inseam is passed through hot wax before stitching. As the stitch is formed, the hot wax flows into the awl holes and solidifies, creating a powerful, flexible seal that is highly resistant to water ingress.

The Strength of a Long Stitch

The inseam often uses long stitches, around 8mm. This robust connection provides a secure and durable anchor point for the welt, ensuring the components remain tightly bound under the stresses of daily wear.

Understanding the Pitfalls

While the inseam is a feature of immense strength, it is also the construction's most critical point of failure. The quality of this hidden stitch separates a truly great shoe from a mediocre one.

Why a Poor Inseam is Catastrophic

A poorly executed inseam can ruin the entire shoe. Inconsistent tension can cause the welt to pull away from the upper, a broken stitch can unravel, and improper sealing will negate any claims of water resistance. The entire shoe's integrity depends on this seam being perfect.

The Challenge of a Hidden Stitch

As a buyer, you cannot visually inspect the inseam on a finished shoe. Its quality is a matter of trust in the shoemaker's skill, standards, and reputation. This is why purchasing Goodyear welted footwear from established, reputable makers is so important; you are paying for the craftsmanship you cannot see.

How to Apply This to Your Purchase

Understanding the inseam's role empowers you to look beyond surface-level features and appreciate the true markers of quality construction.

- If your primary focus is longevity and repairability: Recognize that the integrity of the hidden inseam is the single factor enabling a shoe to be resoled multiple times.

- If your primary focus is weather resistance: Know that the hot-waxed inseam stitch provides the first and most critical line of defense against water entering from the sole.

- If your primary focus is assessing craftsmanship: Acknowledge that while you cannot see the inseam, the reputation and consistency of the shoemaker are your best indicators of its quality.

Ultimately, appreciating the inseam is appreciating the very soul of the shoemaker's craft.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Inseam Stitch (101) | Joins upper, insole, and welt | Creates the structural core |

| Protected Position | Hidden inside the shoe | Shielded from external wear and tear |

| Hot-Waxed Thread | Seals the stitch holes | Provides superior water resistance |

| Long Stitch (8mm) | Creates a robust anchor point | Ensures long-term durability |

Ready to build footwear with uncompromising structural integrity?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including time-tested constructions like Goodyear welting, where the precision of the hidden inseam stitch is paramount to quality.

We can help you deliver the durability and longevity your customers demand. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance