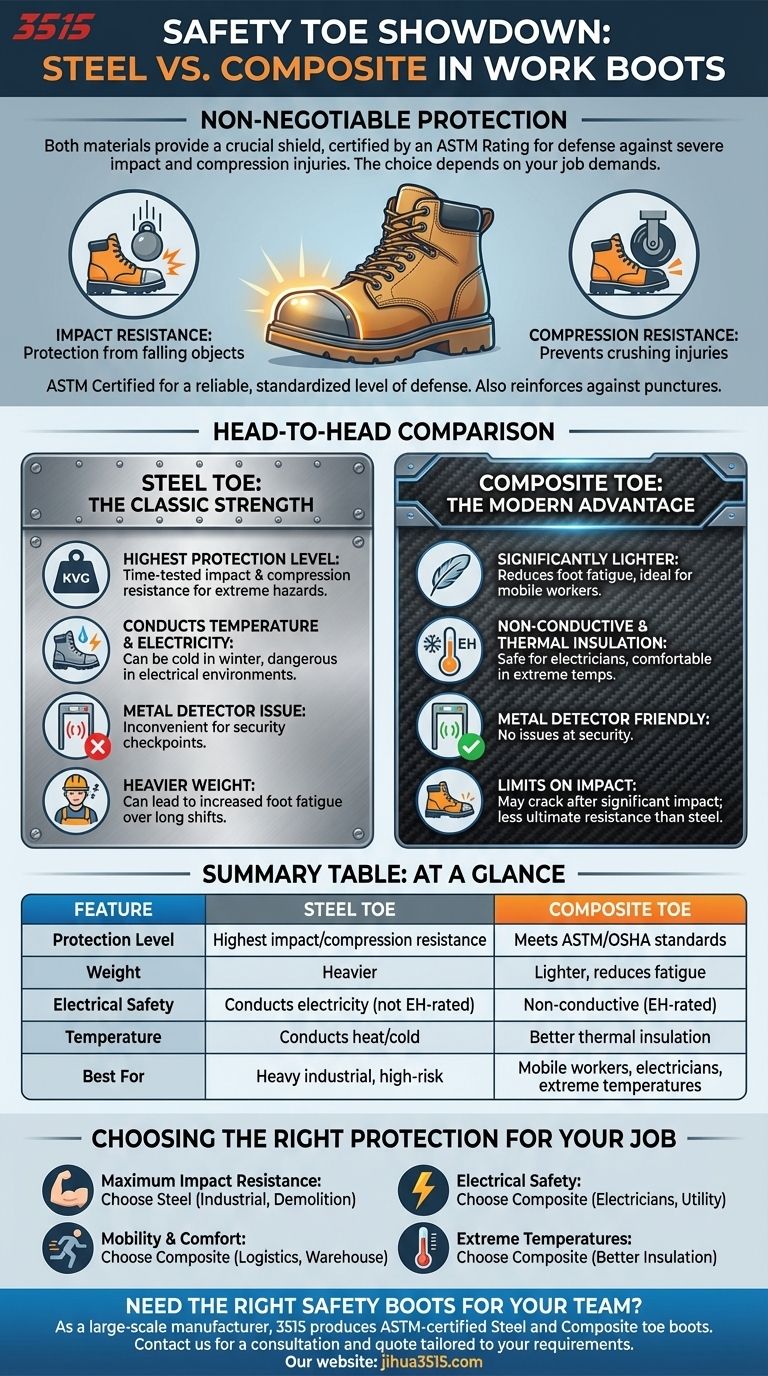

The primary significance of a safety toe is non-negotiable protection. In any environment with a risk of falling or heavy objects, both composite and steel toe caps serve as a crucial shield for your feet. They are engineered to safeguard you from severe impact and compression injuries, with quality boots being certified by an ASTM rating that guarantees a specific level of defense.

The decision is not whether you need a safety toe, but which material—steel or composite—aligns with the specific demands of your job. Steel offers the absolute highest level of impact resistance, while composite provides a modern, lightweight alternative for mobile workers and those in specialized electrical environments.

The Core Function: Impact and Compression Resistance

The fundamental purpose of a safety toe is to prevent crushing injuries. In hazardous workplaces, the risk of dropping heavy tools, materials, or equipment is a constant threat. A reinforced toe box acts as a sturdy barrier against these forces.

What the ASTM Rating Means

High-quality safety boots are rated by the American Society for Testing and Materials (ASTM). This certification indicates that the boot has passed rigorous testing for both impact (from a falling object) and compression (from a rolling object). This rating ensures your footwear provides a reliable, standardized level of protection.

Preventing Punctures and Other Injuries

Beyond direct impact, a reinforced toe area provides structural integrity to the front of the boot. This helps defend against punctures and other injuries that could cause fractures or severe foot damage, making it an essential component of occupational safety.

Steel vs. Composite: A Head-to-Head Comparison

While both materials are designed to protect you, they have distinct properties that make them better suited for different applications. Understanding these differences is key to choosing the right boot.

Protection Level: The Strength of Steel

Steel toes provide the classic, time-tested solution for foot protection. They offer the highest available standard for both impact and compression resistance, making them the default choice for extremely hazardous environments with a high risk of very heavy falling objects.

Weight and Mobility: The Composite Advantage

Composite toes, made from non-metallic materials like carbon fiber, Kevlar, or plastic, are significantly lighter than steel. This reduction in weight minimizes foot fatigue over long shifts and is ideal for mobile workers in logistics, construction, or emergency services who are constantly on the move.

Environmental Factors: Conductivity and Temperature

This is a critical point of difference. Steel is a conductor; it readily transfers both temperature and electricity. In cold environments, steel toe boots can become uncomfortably cold, whereas composite materials provide better thermal insulation.

Crucially, because they are non-metallic, composite toes do not conduct electricity. This makes them the only safe choice for electricians or anyone working in an environment with a risk of electrical hazards requiring an Electrical Hazard (EH) rating.

Convenience and Comfort

Composite toes have the added benefit of not setting off metal detectors, a major convenience for workers who frequently pass through security checkpoints. While fit can vary by brand, the reduced weight of composite boots generally contributes to greater overall comfort during long periods of wear.

Understanding the Trade-offs

Neither material is a perfect solution for every scenario. Being aware of the inherent compromises is essential for making an informed decision.

The Limits of Composite Toes

While composite toe caps meet or exceed all ASTM and OSHA requirements, they typically do not offer the same ultimate level of impact resistance as steel. After a significant impact, a composite toe may crack or shatter, whereas a steel toe is more likely to dent but remain intact. For the absolute highest level of protection, steel maintains an edge.

The Downsides of Steel Toes

The primary drawback of steel is its weight. The added ounces on each foot can lead to increased fatigue by the end of the day, particularly for workers who walk long distances. Furthermore, its conductivity of heat and cold can be a significant comfort issue in extreme weather conditions.

Choosing the Right Protection for Your Job

Your work environment and daily tasks should be the deciding factors. The right choice is the one that provides the necessary protection without hindering your performance.

- If your primary focus is maximum impact resistance: Choose steel toe boots for the highest level of protection, especially in heavy industrial, demolition, or logging environments.

- If your primary focus is mobility and all-day comfort: Choose composite toe boots to reduce weight and fatigue, ideal for logistics, warehouse work, or any job requiring constant movement.

- If your primary focus is electrical safety: You must choose composite toe boots for their non-conductive properties, which are essential for electricians and utility workers.

- If your primary focus is working in extreme temperatures: Choose composite toe boots for their superior thermal insulation, keeping your feet more comfortable in both hot and cold conditions.

Selecting the right safety toe is a critical decision that directly enhances both your safety and your daily performance on the job.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Protection Level | Highest impact/compression resistance | Meets ASTM/OSHA standards |

| Weight | Heavier | Lighter, reduces fatigue |

| Electrical Safety | Conducts electricity (not EH-rated) | Non-conductive (EH-rated) |

| Temperature | Conducts heat/cold | Better thermal insulation |

| Best For | Heavy industrial, high-risk environments | Mobile workers, electricians, extreme temperatures |

Need the right safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified steel and composite toe boots for distributors, brand owners, and bulk clients. We provide the precise protection your workforce needs, combining safety with all-day comfort.

Contact us today for a consultation and get a quote tailored to your requirements.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- What are the key differences between steel toe and composite toe caps? Choose the Right Safety for Your Job

- What types of steel are used in steel toe caps? Choose the Right Protection for Your Worksite

- What are some common alternatives to steel-toe boots? Alloy & Composite Toes Explained

- What are the alternatives to steel toe boots for safety? Discover Lighter, Safer Options

- Are steel toe shoes unsafe for electricians? Debunking the EH-Rated Footwear Myth

- What steps should employers take to ensure workers wear steel toe shoes? Build a Robust Safety Compliance System

- How do weather conditions affect the choice between steel and non-steel safety toes? Choose the Right Toe for Extreme Temperatures