The foam layer in the new jungle boot serves two critical, distinct functions. It provides significant shock absorption to reduce fatigue, and more importantly, it creates a protective barrier that prevents microbes in wet environments from degrading the bond between the boot's upper and the sole.

The foam layer is not just a comfort feature; it is a structural solution engineered to solve the primary cause of boot failure in jungle environments—the microbial breakdown of the adhesives that hold the boot together.

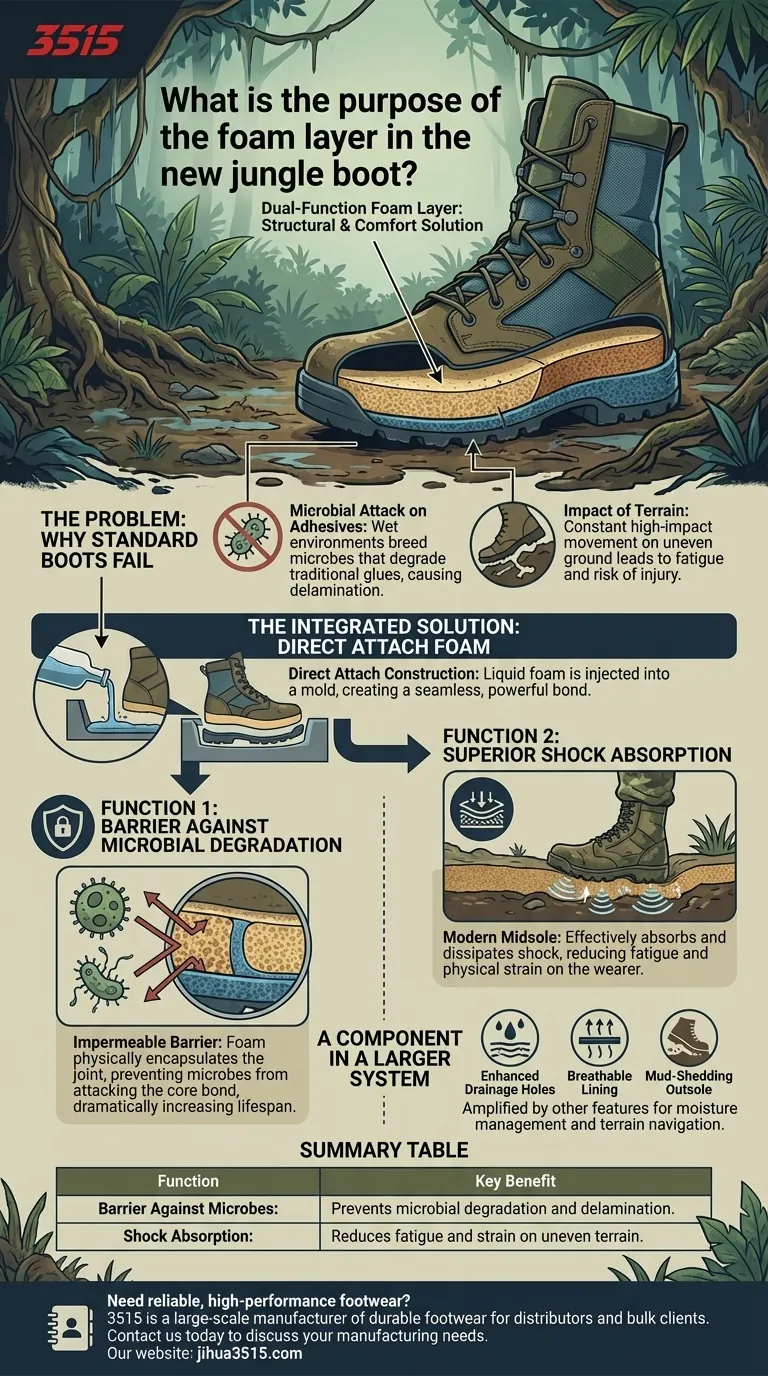

The Problem: Why Standard Boots Fail in the Jungle

To understand the foam layer's purpose, we must first understand the environment it was designed to overcome. Standard-issue combat boots, optimized for dry climates, quickly fail in hot, wet conditions for two primary reasons.

The Attack on Adhesives

Hot and wet environments are ideal breeding grounds for microbes. These microorganisms aggressively attack and degrade the traditional glues and adhesives used to bond the sole of a boot to its upper.

This leads to delamination, where the sole peels away from the rest of the boot, rendering it useless. It is a catastrophic and common point of failure.

The Impact of Terrain

Jungle terrain is relentlessly uneven, requiring constant navigation over roots, rocks, and mud. This continuous, high-impact movement places enormous stress on both the soldier's body and the boot's construction.

Without adequate cushioning, this leads to increased fatigue and a higher risk of injury, directly impacting operational effectiveness.

The Foam Layer as an Integrated Solution

The new jungle boot's foam layer is part of a "direct attach" construction method that addresses both environmental and physical challenges head-on.

Function 1: A Barrier Against Microbial Degradation

Instead of relying solely on surface glue, the boot is assembled by injecting liquid foam into a mold that joins the upper directly to the rubber outsole.

When this foam solidifies, it creates a single, seamless, and powerful bond. This foam physically encapsulates the joint, creating an impermeable barrier that microbes cannot penetrate to attack the core bonding agents. This dramatically increases the boot's structural lifespan.

Function 2: Superior Shock Absorption

This same foam layer serves as a modern midsole, a feature largely absent in older jungle boot designs like the Vietnam-era M1966.

It effectively absorbs and dissipates the shock from walking and running on hard, uneven ground. This added cushioning significantly enhances comfort and reduces physical strain on the wearer.

A Component in a Larger System

The foam layer does not work in isolation. Its effectiveness is amplified by other design features, such as enhanced drainage holes, a breathable lining for faster drying, and a mud-shedding outsole. Together, these elements create a holistic system for managing moisture and traversing difficult terrain.

How to Apply This Understanding

This design philosophy provides a clear model for evaluating footwear intended for extreme, wet environments.

- If your primary focus is durability: The key is the direct-attach construction. The foam isn't just glued in; it is the bond, protecting the boot from the delamination that plagues traditionally assembled footwear.

- If your primary focus is performance and comfort: The foam acts as a crucial shock-absorbing midsole, reducing fatigue and allowing for greater effectiveness during prolonged use in harsh conditions.

- If your primary focus is overall reliability: The foam layer is a multi-function solution that simultaneously enhances structural integrity and wearer comfort, addressing the two biggest weaknesses of older boot designs.

Ultimately, the foam layer transforms the jungle boot from a simple piece of footwear into a durable, resilient platform engineered to perform in its intended environment.

Summary Table:

| Function | Key Benefit |

|---|---|

| Barrier Against Microbes | Prevents microbial degradation of adhesives, stopping sole delamination. |

| Shock Absorption | Reduces fatigue and physical strain on uneven terrain. |

| Integrated Construction | Creates a seamless, durable bond via direct-attach molding. |

Need reliable, high-performance footwear for demanding environments? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots engineered for extreme conditions, combining structural integrity with wearer comfort. Contact us today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

People Also Ask

- What is the proper method to clean military boots? A Step-by-Step Guide to Maximize Longevity

- What are the essential steps for cleaning military boots? A Complete Guide to Preserve Your Gear

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What are the steps to clean suede military boots? A Complete Guide to Gentle, Effective Care