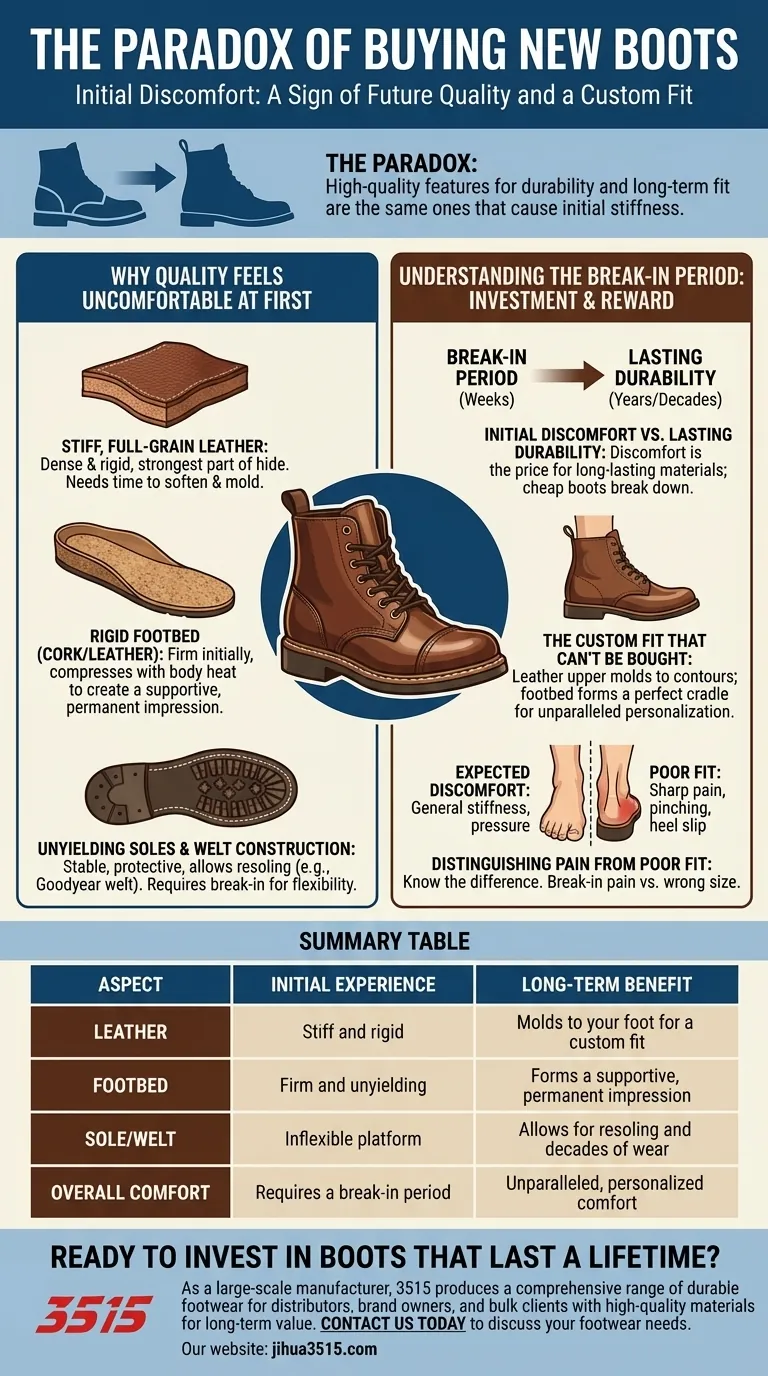

The paradox of buying new boots is a common experience for anyone investing in high-quality footwear. It states that the very features that signify durability and a superior long-term fit—such as thick, full-grain leather and robust soles—are the same features that make the boots initially stiff and uncomfortable.

The core insight is that with well-made boots, initial discomfort is often a sign of future quality. You are not just buying a finished product; you are starting a process of molding a durable, raw material into a perfectly customized fit for your foot.

Why Quality Feels Uncomfortable at First

The initial stiffness of a premium boot is not a design flaw; it is a direct consequence of the high-grade materials used in its construction. These components are chosen for their ability to withstand years of wear and to eventually conform to your unique anatomy.

The Role of Stiff, Full-Grain Leather

High-quality boots use full-grain or top-grain leather, which is the strongest and most durable part of the hide. This leather is dense and rigid when new, requiring time and wear to soften, stretch, and crease in a way that matches your foot's shape and movement.

The Purpose of a Rigid Footbed

Many well-constructed boots feature a footbed made of materials like cork and leather. Unlike a soft foam insole that feels comfortable immediately but collapses over time, a cork footbed is firm at first. As you walk, your body heat and pressure gradually compress the cork, creating a permanent, supportive impression of your foot.

Unyielding Soles and Welt Construction

The sole of a new boot is often thick and inflexible, providing a stable platform that protects your foot. Construction methods like a Goodyear welt add a layer of rigidity but allow the boot to be resoled multiple times, drastically extending its lifespan. This robust build requires a break-in period to develop flexibility.

Understanding the Trade-offs: The Break-in Period

Navigating the paradox requires understanding the fundamental trade-off between immediate comfort and long-term value. The break-in period is the investment of time and patience required to unlock the full potential of your boots.

Initial Discomfort vs. Lasting Durability

Boots made from cheaper, softer materials often feel great right out of the box but break down quickly. The discomfort of a quality boot is the price of admission for materials that will last for years, if not decades, and develop a unique character over time.

The Custom Fit That Can't Be Bought

The break-in process is what creates a truly custom fit. The leather upper molds around the unique contours of your ankle and forefoot, while the footbed forms a perfect cradle for the sole of your foot. This level of personalization is something that cannot be achieved with softer, mass-produced footwear.

Distinguishing Pain from Poor Fit

It is crucial to differentiate between the expected discomfort of breaking in a boot and the sharp pain of a poor fit. General stiffness and pressure are normal. However, pinching, sharp pain in your toes, or excessive heel slip are signs that the boot is the wrong size or shape (last) for your foot.

Making the Right Choice for Your Boots

Understanding this paradox helps you manage expectations and select the right footwear for your needs.

- If your primary focus is longevity and a perfect custom fit: Be prepared to invest in a well-made boot and endure a break-in period of a few weeks for a product that will last years.

- If your primary focus is immediate, out-of-the-box comfort for casual or short-term use: A boot made with softer, more flexible materials may be a more suitable, albeit less durable, choice.

Ultimately, embracing the break-in process is an investment in unparalleled comfort and durability down the road.

Summary Table:

| Aspect | Initial Experience | Long-Term Benefit |

|---|---|---|

| Leather | Stiff and rigid | Molds to your foot for a custom fit |

| Footbed | Firm and unyielding | Forms a supportive, permanent impression |

| Sole/Welt | Inflexible platform | Allows for resoling and decades of wear |

| Overall Comfort | Requires a break-in period | Unparalleled, personalized comfort |

Ready to Invest in Boots That Last a Lifetime?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots built with the high-quality materials that ensure long-term value and a perfect fit.

Contact us today to discuss your footwear needs and discover how we can deliver superior quality and reliability for your business.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How does a 3D measurement microscope contribute to the analysis of surface roughness? Master Precision Surface Mapping

- Why is efficient equipment scheduling critical for mixed footwear production? Maximize Asset Turnover & Efficiency

- What are the benefits of wearing lightweight shoes? Reduce Fatigue & Boost Comfort for Work & Play

- What are some effective ways to keep feet warm during winter cycling? A Complete Guide to Warm Feet

- What cultural significance do cowboy boots hold? Unpacking Their Symbolism & Modern Appeal

- What steps are involved in cleaning and conditioning cowboy boots? A Complete Guide to Preserving Your Leather

- What are the benefits of using insulated insoles in winter cycling shoes? Stay Warm and Ride Comfortably

- What should be considered when fitting cowboy boots? A Guide to the Perfect, Secure Fit