The 'Occasional Footwear Standard', officially designated as AS/NZS 2210.5, is a set of criteria used to certify footwear that requires certain safety features but does not have a protective toecap. It primarily tests for essential qualities like non-slip sole performance, material durability, and ergonomic design to ensure reliability in low-risk work environments.

This standard certifies footwear for jobs where slip resistance and durability are necessary, but protection from impact or compression hazards is not. It is fundamentally different from a true safety boot standard, which always includes a protective toecap.

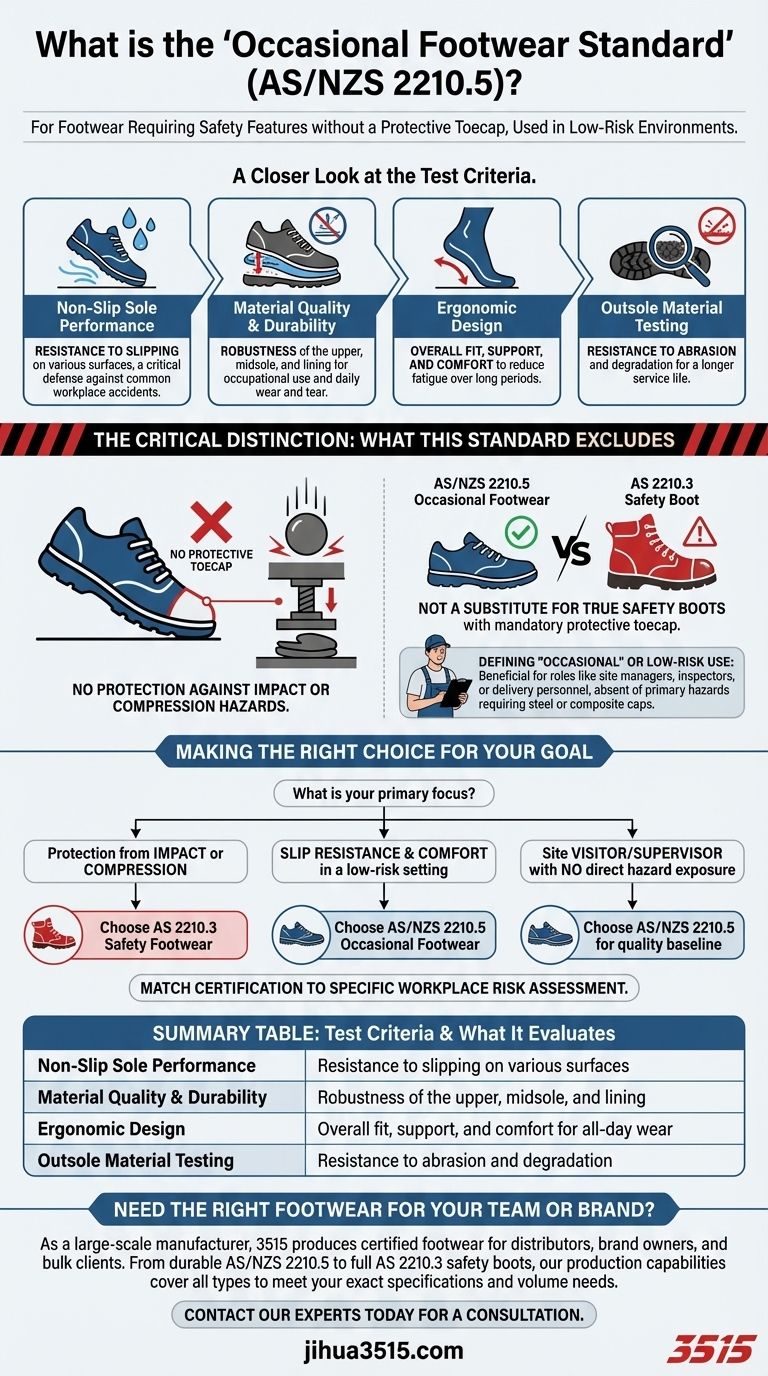

A Closer Look at the Test Criteria

Footwear certified to AS/NZS 2210.5 undergoes a specific series of tests to validate its performance and construction, even without the inclusion of a safety toecap.

Non-Slip Sole Performance

This is a critical safety component of the standard. The test evaluates the outsole's ability to resist slipping on various surfaces, providing a crucial defense against one of the most common workplace accidents.

Material Quality and Durability

The standard scrutinizes the quality of the materials used throughout the shoe. This includes the upper, midsole, and lining, ensuring they are robust enough for occupational use and can withstand daily wear and tear.

Ergonomic Design

Ergonomics testing assesses the overall design and fit of the footwear. The goal is to ensure it provides adequate support and comfort for the wearer, reducing fatigue over long periods.

Outsole Material Testing

Beyond slip resistance, the outsole itself is tested for durability. This confirms the material can resist abrasion and degradation from contact with various surfaces, ensuring a longer service life.

The Critical Distinction: What This Standard Excludes

Understanding what AS/NZS 2210.5 does not cover is the most important factor in its application. Misinterpreting this standard can lead to significant workplace safety risks.

The Absence of a Protective Toecap

The defining characteristic of this standard is the lack of a protective toecap. Footwear certified to AS/NZS 2210.5 offers no protection against impact from falling objects or compression from heavy equipment.

Not a Substitute for True Safety Boots

This footwear must not be used in environments where there is any risk of foot injury from impact or crushing. For those hazards, you must use footwear certified to the safety footwear standard AS 2210.3, which mandates a protective toecap.

Defining "Occasional" or Low-Risk Use

This standard is intended for roles where safety features like slip resistance are beneficial, but the primary hazards requiring a steel or composite cap are absent. Examples include site managers, inspectors, or delivery personnel who may enter a workshop but are not directly involved in hazardous manual tasks.

Making the Right Choice for Your Goal

Selecting the correct footwear requires a clear understanding of your workplace environment and its specific risks.

- If your primary focus is protection from impact or compression: You must choose footwear certified to the AS 2210.3 safety standard.

- If your primary focus is slip resistance and all-day comfort in a low-risk setting: Footwear meeting the AS/NZS 2210.5 standard is a suitable and appropriate choice.

- If you are a site visitor or supervisor with no direct hazard exposure: This standard provides a baseline of quality and slip resistance without the weight and rigidity of a protective toecap.

Ultimately, matching your footwear's certification to your specific workplace risk assessment is the only way to ensure true safety.

Summary Table:

| Test Criteria | What It Evaluates |

|---|---|

| Non-Slip Sole Performance | Resistance to slipping on various surfaces |

| Material Quality & Durability | Robustness of the upper, midsole, and lining |

| Ergonomic Design | Overall fit, support, and comfort for all-day wear |

| Outsole Material Testing | Resistance to abrasion and degradation |

Need the right footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. Whether you require durable AS/NZS 2210.5 occasional footwear with superior slip resistance or full AS 2210.3 safety boots with protective toecaps, our production capabilities cover all types of shoes and boots to meet your exact specifications and volume needs.

Contact our experts today for a consultation and let us help you equip your workforce with the right footwear for their safety and comfort.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management