In footwear production, the most common vulcanization method is the use of an autoclave, which is essentially a large, industrial pressure oven. This process involves heating the assembled shoe components under high pressure to initiate a chemical reaction that permanently bonds the rubber parts to each other and to the shoe's upper.

The core principle is not just heating, but using a combination of heat and pressure to chemically transform raw rubber into a strong, unified, and elastic sole structure that is permanently fused to the shoe.

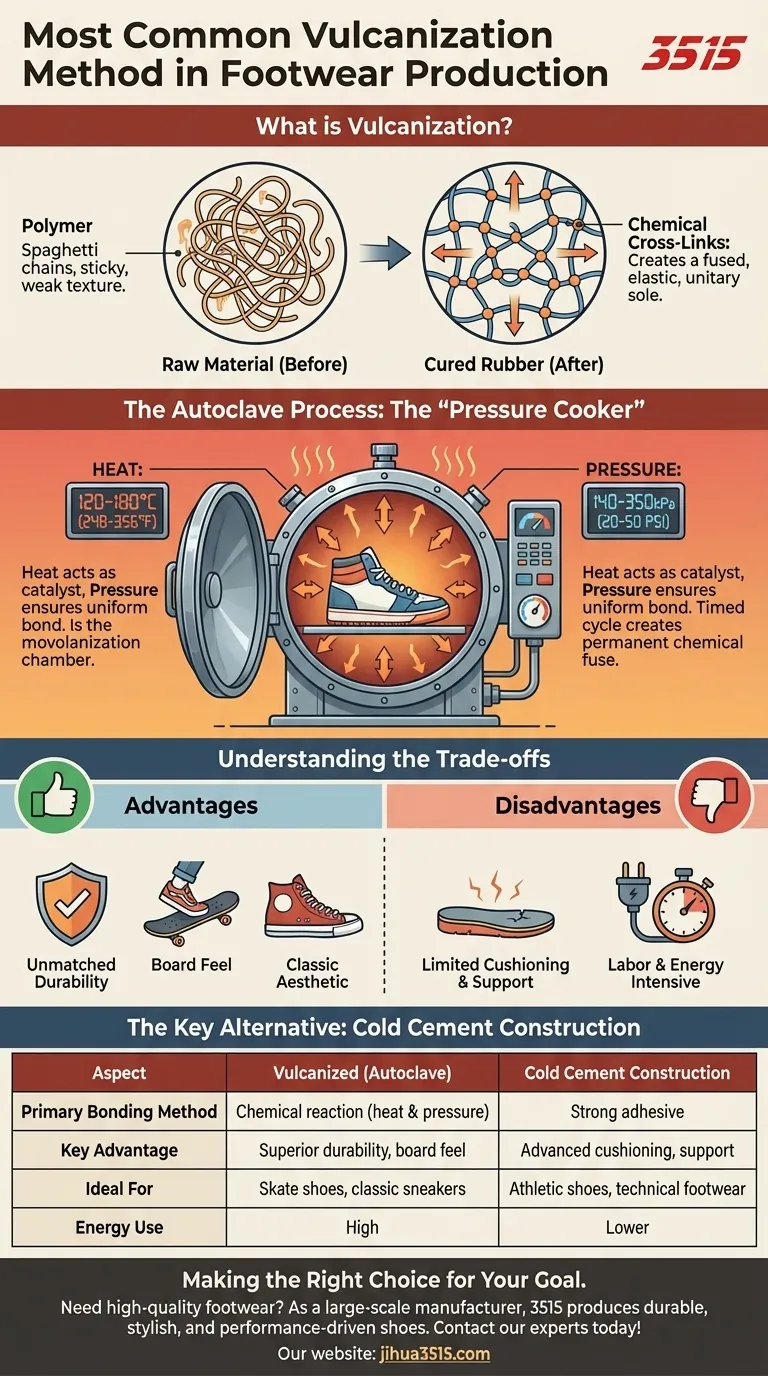

What is Vulcanization, and Why Does it Matter?

To appreciate why autoclaves are used, we first need to understand the fundamental process of vulcanization. It's a chemical transformation that gives rubber the properties we associate with footwear.

From Raw Material to Durable Rubber

Natural rubber is inherently sticky, weak, and deforms easily with temperature changes. Vulcanization solves this by adding a curing agent (most commonly sulfur) and applying heat.

This process creates chemical cross-links between the long polymer chains within the rubber.

The Chemical Transformation

Imagine the polymer chains as loose strands of spaghetti. The cross-linking process is like adding connections that tie all the strands together into a single, resilient net.

This changes the rubber from a plastic material (one that deforms permanently) to an elastic material (one that returns to its original shape).

The Result: A Fused, Unitary Sole

In footwear, vulcanization doesn't just treat the outsole. It simultaneously fuses the rubber outsole, the sidewall tape (foxing), and the toe cap directly to the canvas or leather upper, creating a single, inseparable unit.

The Autoclave Process Explained

An autoclave provides the specific, controlled environment needed to execute this chemical reaction perfectly on an industrial scale.

A "Pressure Cooker" for Shoes

Think of an autoclave as a highly precise pressure cooker. Shoes are loaded inside, the chamber is sealed, and the environment is carefully controlled.

The key operating parameters are heat and pressure, typically in the range of 120-180°C (248-356°F) and 140-350kPa (20-50 PSI).

The Role of Heat and Pressure

Heat is the catalyst that initiates and accelerates the cross-linking reaction. At a temperature like 170°C, this reaction can begin in as little as 10 minutes.

Pressure is equally critical. It forces all rubber components tightly against each other and the upper, eliminating air pockets and ensuring a complete, uniform bond across every surface.

A Precisely Timed Cycle

The entire cycle is carefully timed. Insufficient time results in incomplete vulcanization and a weak bond. Too much time can over-cure the rubber, making it brittle and prone to cracking.

Understanding the Trade-offs

Vulcanized construction offers distinct advantages, but it also comes with limitations that make it unsuitable for certain types of footwear.

Advantage: Unmatched Durability and Board Feel

The primary benefit is durability. Because the sole is chemically fused to the upper, it is extremely resistant to delamination or separation.

This construction also results in a thin, flexible sole that provides excellent ground feedback, often called "board feel," which is highly valued in skateboarding.

Advantage: A Classic, Timeless Aesthetic

The process creates the iconic look of classic sneakers like Converse Chuck Taylors or Vans Authentics, characterized by the wrapped rubber foxing tape.

Disadvantage: Limited Cushioning and Support

The simple, heat-fused construction does not easily accommodate complex, multi-density foam midsoles (like EVA) used in modern athletic running shoes. This generally means less cushioning and arch support.

Disadvantage: More Labor and Energy Intensive

Vulcanized shoe construction often requires more manual labor, particularly for precisely wrapping the foxing tape. The process of heating a large autoclave is also very energy-intensive compared to other methods.

The Key Alternative: Cold Cement Construction

To fully understand vulcanization, it helps to compare it to its main alternative.

Vulcanized: A Heat-Forged Bond

As we've covered, this method uses a chemical reaction triggered by heat and pressure to "weld" the shoe components into one piece.

Cold Cement: An Adhesive-Based Assembly

In cold cement construction, the shoe upper and the pre-molded sole unit are manufactured separately and then joined together using a strong adhesive. This is the dominant method for modern running shoes, as it allows for complex sole units made from multiple materials like foam, plastic, and rubber.

Making the Right Choice for Your Goal

Understanding these two construction methods allows you to select footwear based on its intended performance and characteristics.

- If your primary focus is durability, board feel, and classic style: Vulcanized construction is the definitive choice for skate shoes and heritage sneakers.

- If your primary focus is advanced cushioning, arch support, or lightweight performance: Cold cement construction is better suited for athletic shoes, hikers, and technical footwear.

Ultimately, knowing how a shoe is made empowers you to look beyond the brand and understand the functional trade-offs inherent in its design.

Summary Table:

| Aspect | Vulcanized Construction (Autoclave) | Cold Cement Construction |

|---|---|---|

| Primary Bonding Method | Chemical reaction (heat & pressure) | Strong adhesive |

| Key Advantage | Superior durability, board feel | Advanced cushioning, support |

| Ideal For | Skate shoes, classic sneakers | Athletic shoes, technical footwear |

| Energy Use | High (energy-intensive) | Lower |

Need high-quality vulcanized or cold cement footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, stylish, and performance-driven shoes and boots for distributors, brand owners, and bulk clients. Let us help you select the perfect construction method for your market. Contact our experts today to discuss your production needs!

Visual Guide

Related Products

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What is the primary purpose of safety shoes? Your Ultimate Guide to Workplace Foot Protection

- How do safety shoes protect you? A Guide to Essential Footwear Safety Features

- Why is proper fit crucial for safety toe boots? Avoid These Hidden Hazards

- What are the key considerations for finding a perfect fitting safety toe boot? Avoid Injury and Discomfort

- How can you determine the right safety toe boot for your workplace? Match Boots to Hazards