My primary goal is to provide you with the most relevant information to make an informed choice. Based on my research and understanding, composite toe boots offer superior insulation compared to steel toe boots. This isn't just a simple statement; it's a foundation for a broader discussion to ensure you're getting the right boot for your needs.

The real choice is about balancing thermal and electrical hazards (composite) versus ultimate impact/compression resistance (steel).

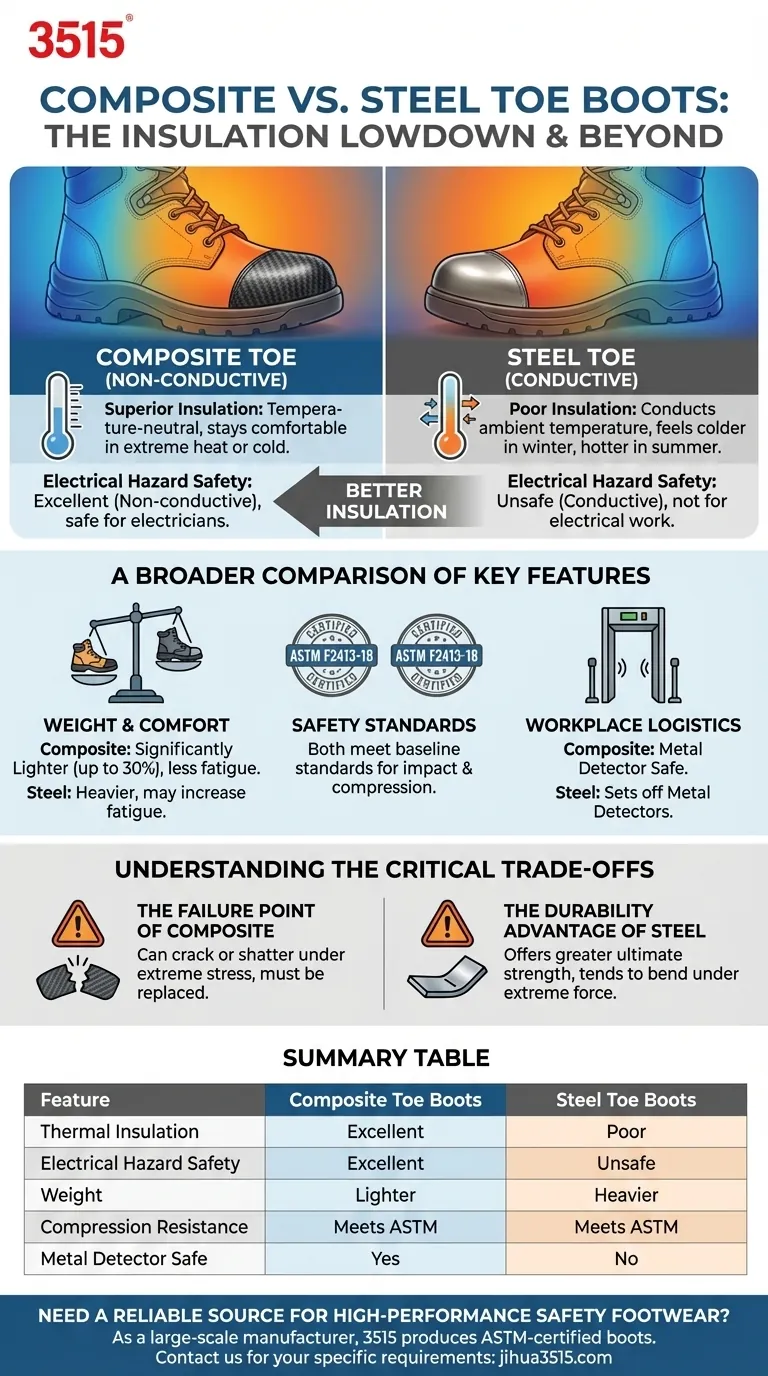

The core of this difference lies in the materials. Composite toes are made of non-metallic materials like carbon fiber, Kevlar, or plastic. These materials don't conduct heat or cold, making them "temperature-neutral," offering enhanced insulation. Steel, however, is a metal and an excellent conductor. That means steel toe boots will feel colder in the winter and hotter in the summer, transferring the ambient temperature to your feet. Furthermore, the non-conductive nature of composite toes makes them ideal for environments with electrical hazards, a critical factor for electricians or those working around electrical equipment.

Beyond insulation, several other factors need consideration. Composite boots are lighter, leading to less fatigue over a long workday. Both steel and composite boots meet ASTM F2413-18 standards for impact and compression resistance, providing a baseline of protection. However, steel excels in durability under extreme circumstances. Steel can withstand greater compression without cracking, while composite materials can crack or shatter under extreme stress, compromising their protection. Steel may also be a drawback in environments where metal detectors are used.

Ultimately, the right choice depends on your specific work environment and associated hazards.

**If your primary focus is working in extreme hot or cold temperatures or electrical hazards:**Choose composite toe boots for their superior insulation and electrical safety.**If your primary focus is protection against crushing weight or heavy impact:**Steel toe boots offer superior compression resistance and are ideal for heavy industrial or construction sites.**If your primary focus is all-day comfort and minimizing fatigue:**The lighter weight of composite toe boots makes them the better option.

With this in mind, you can confidently select the safety boot best suited for your specific job demands and environmental risks. In a direct comparison, composite toe boots offer significantly better insulation than steel toe boots. The non-metallic materials used in composite toes—such as Kevlar, carbon fiber, or plastic—do not conduct heat or cold. In contrast, the metal in steel toe boots readily transfers ambient temperatures, making your feet feel much colder in the winter and hotter in direct sun.

The decision between composite and steel toe boots extends far beyond insulation. It is a fundamental trade-off between thermal and electrical protection on one side (composite) and maximum impact and compression resistance on the other (steel).

The Core Difference: How Materials Dictate Performance

Thermal Insulation Properties

Composite toe caps are made from materials that are inherently poor conductors of temperature.

This makes them "temperature-neutral," providing superior insulation that keeps your feet more comfortable in both extreme heat and cold.

Electrical Conductivity

Steel is an excellent electrical conductor, making steel toe boots fundamentally unsafe and unsuitable for environments with live electrical hazards.

Composite materials do not conduct electricity. This makes them the mandatory choice for electricians or any worker requiring an Electrical Hazard (EH) rated boot.

A Broader Comparison of Key Features

Weight and All-Day Comfort

Composite toe boots are significantly lighter than their steel counterparts, sometimes by as much as 30%.

This reduction in weight directly translates to less foot fatigue and greater comfort over a long workday.

Meeting Safety Standards

Both modern steel and composite toe boots are engineered to meet the same ASTM F2413-18 standards for impact and compression resistance.

This means that for the vast majority of workplace incidents, both provide a certified and reliable level of protection against falling objects and compression.

Workplace Logistics

Because they contain no metal, composite toe boots will not set off metal detectors. This makes them a practical choice for workers in high-security environments like airports or power plants.

Understanding the Critical Trade-offs

The Durability Advantage of Steel

While both meet the baseline standard, steel offers greater ultimate strength. Under extreme force that exceeds ASTM limits, steel is more likely to bend rather than break.

This makes steel the preferred choice in heavy industrial environments where the risk of catastrophic crushing weight is highest.

The Failure Point of Composite

Composite materials are incredibly strong, but they can crack or shatter upon a single, severe impact or under an extreme compression load.

Once a composite cap's integrity is compromised in this way, it offers no further protection, and the boots must be replaced immediately.

Making the Right Choice for Your Environment

Your ideal safety boot depends entirely on the specific and most probable hazards of your work environment.

- If your primary focus is working in extreme temperatures or around electrical hazards: Choose composite toe boots for their superior insulation and non-conductive safety.

- If your primary focus is maximum protection against crushing weight or heavy impact: Choose steel toe boots for their superior compression strength and proven durability in industrial settings.

- If your primary focus is all-day comfort and minimizing fatigue: Choose composite toe boots for their significantly lighter weight.

By prioritizing the most critical safety feature for your job, you can confidently select the boot that offers the right protection for your needs.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Thermal Insulation | Excellent (Non-conductive) | Poor (Conductive) |

| Electrical Hazard Safety | Excellent (Non-conductive) | Unsafe (Conductive) |

| Weight | Lighter | Heavier |

| Compression Resistance | Meets ASTM Standards | Meets ASTM Standards |

| Metal Detector Safe | Yes | No |

Need a Reliable Source for High-Performance Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified composite and steel toe boots for distributors, brand owners, and bulk clients. We ensure your workforce has the right protection, whether the priority is superior insulation, electrical safety, or maximum durability.

Let's discuss your specific requirements: Contact our team today to get a quote or request samples.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- What are the benefits of heavy duty work boots? Invest in Superior Safety & Durability

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?