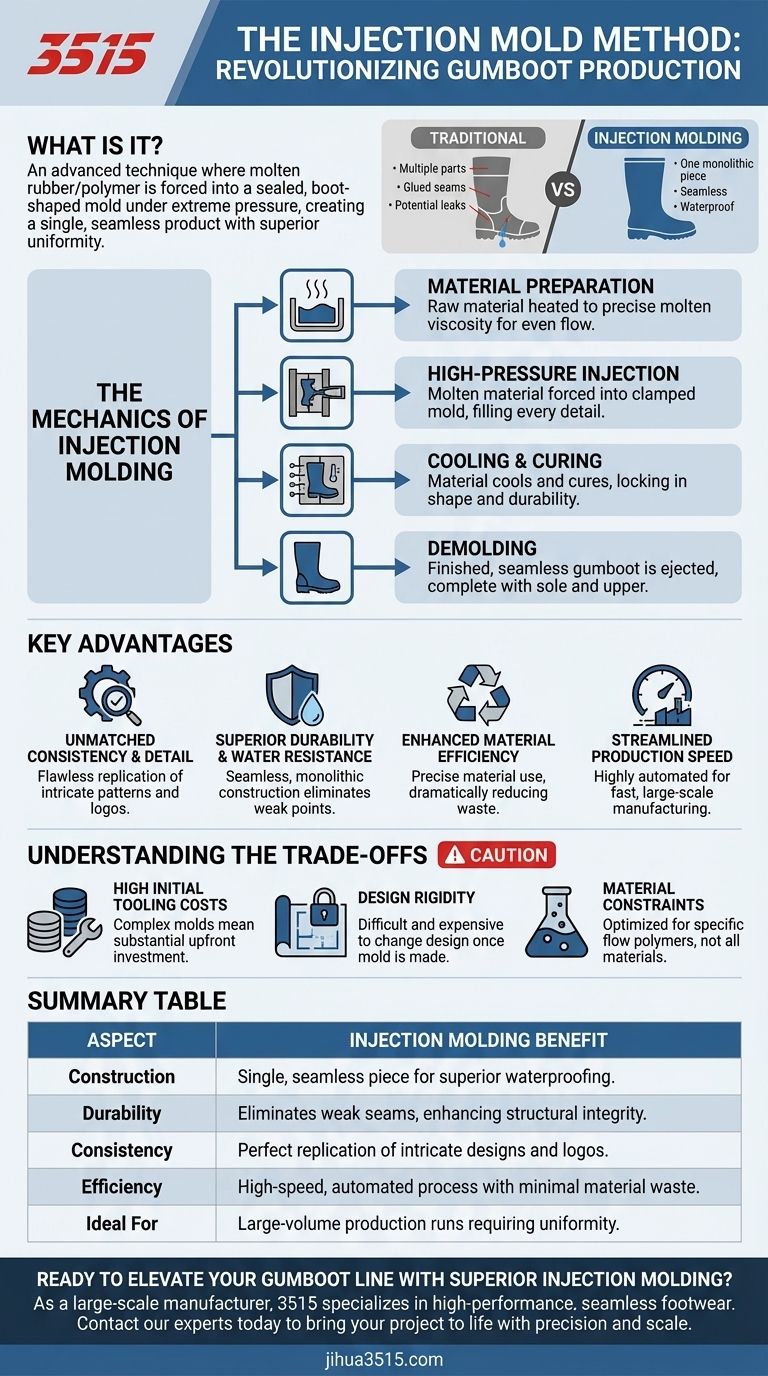

The injection mold method is an advanced manufacturing technique where molten rubber or polymer is forced directly into a sealed boot-shaped mold under extremely high pressure. This process creates a single, seamless product, ensuring superior uniformity, intricate design replication, and a significant reduction in material waste compared to traditional assembly methods.

While older techniques involve cutting and bonding separate pieces, the core advantage of injection molding is its ability to produce a monolithic, waterproof gumboot with unparalleled consistency and structural integrity directly from raw material.

The Mechanics of Injection Molding

Understanding the process reveals why it yields such a high-quality product. The method is a precise, multi-stage operation that transforms molten material into a finished boot.

Step 1: Material Preparation

The raw material, typically a specialized rubber or PVC polymer, is heated until it reaches a specific molten viscosity. This ensures it can flow evenly and completely fill the mold.

Step 2: High-Pressure Injection

This is the critical step. The molten material is injected into a clamped, two-part metal mold at high pressure. This force ensures the material reaches every single crevice and detail of the mold cavity.

Step 3: Cooling and Curing

Once the mold is filled, it undergoes a controlled cooling process. This allows the material to solidify and cure, locking in the boot's final shape, durability, and details.

Step 4: Demolding

After curing, the mold is opened, and the finished, single-piece gumboot is ejected. The result is a complete boot, including the sole and upper, with no seams or bonded joints.

Key Advantages in Gumboot Production

The shift to injection molding is driven by clear, measurable benefits in quality, efficiency, and design freedom.

Unmatched Consistency and Detail

The high pressure of the injection process forces the material to conform perfectly to the mold's interior. This allows for the flawless replication of intricate patterns, logos, and textures on every single unit.

Superior Durability and Water Resistance

A traditionally assembled boot has seams, which are potential points of failure and water entry. An injection-molded gumboot is a single, seamless piece, eliminating the weakest links and creating a fundamentally more waterproof and durable product.

Enhanced Material Efficiency

This method is incredibly efficient, using only the precise amount of material needed to fill the mold. This dramatically reduces the scrap and wastage associated with cutting patterns from large sheets of rubber.

Streamlined Production Speed

Injection molding is a highly automated and rapid process. It allows for fast cycle times, making it ideal for large-scale production runs where speed and consistency are paramount.

Understanding the Trade-offs

Despite its significant advantages, the injection mold method is not a universal solution. Acknowledging its limitations is key to making an informed decision.

High Initial Tooling Costs

The steel molds used in injection molding are complex, precision-engineered tools. The initial cost to design and manufacture a mold can be substantial, making this method less economical for very small or experimental production runs.

Design Rigidity

Once a mold is created, making significant changes to the design is difficult and expensive. The process favors a finalized design that will be produced in high volumes.

Material Constraints

The process is optimized for specific thermoplastic and thermosetting polymers that have the right flow properties when molten. It is not suitable for every type of material that could be used in footwear.

Making the Right Choice for Your Goal

Selecting the right production method depends entirely on your project's specific priorities, from scale to design intent.

- If your primary focus is large-scale production and absolute durability: The seamless, monolithic construction of an injection-molded boot makes it the superior choice.

- If your primary focus is intricate design and brand consistency: This method excels at reproducing complex details with perfect fidelity across thousands of units.

- If your primary focus is low-volume or bespoke manufacturing: The high upfront tooling cost may make traditional fabrication methods more economically viable.

Ultimately, injection molding empowers the production of a more reliable, detailed, and cost-effective gumboot at scale.

Summary Table:

| Aspect | Injection Molding Benefit |

|---|---|

| Construction | Single, seamless piece for superior waterproofing |

| Durability | Eliminates weak seams, enhancing structural integrity |

| Consistency | Perfect replication of intricate designs and logos |

| Efficiency | High-speed, automated process with minimal material waste |

| Ideal For | Large-volume production runs requiring uniformity |

Ready to elevate your gumboot line with superior injection molding?

As a large-scale manufacturer, 3515 specializes in producing high-performance, seamless footwear for distributors, brand owners, and bulk clients. Our advanced injection molding capabilities ensure your gumboots are durable, perfectly detailed, and manufactured with exceptional efficiency.

Contact our experts today to discuss how we can bring your next project to life with precision and scale.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards