At its core, the midsole is the primary determinant of a boot's structural lifespan. While the outsole provides grip and the upper protects your foot, the midsole is the component that absorbs impact and provides foundational support. Its material composition dictates how long the boot can maintain its shape, stability, and comfort under the stress of repeated use.

The most critical factor for boot durability is not the rugged outsole you see, but the hidden midsole material. A midsole made from a compression-resistant material like Polyurethane (PU) will provide years of stable support, while one made from a softer material like EVA will degrade much faster.

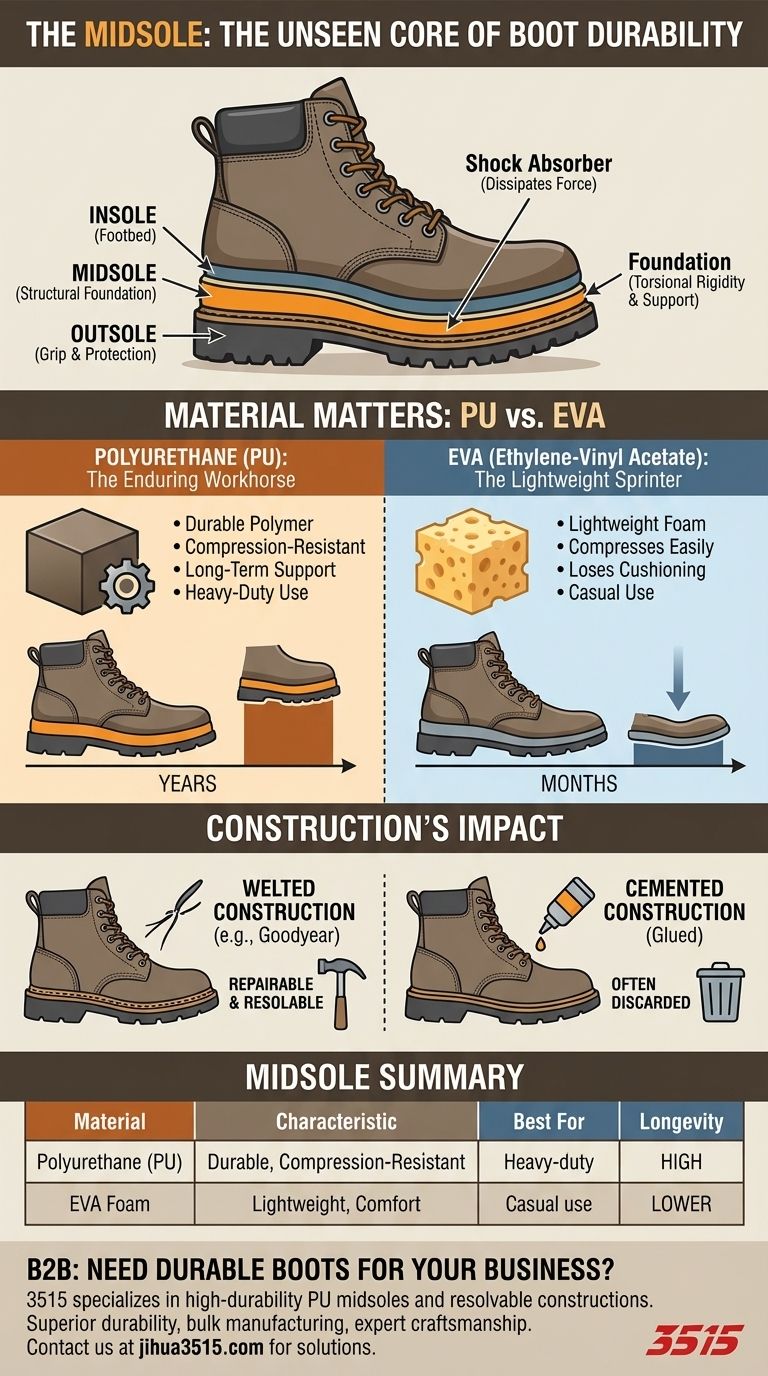

The Midsole: A Boot's Structural Skeleton

The midsole is the layer sandwiched between the insole (footbed) and the outsole (the part that touches the ground). It serves two functions that are critical to both comfort and durability.

Its Role as a Shock Absorber

First, the midsole provides cushioning. It dissipates the force of each step, reducing the impact that travels up through your feet and joints.

Its Role as a Foundation

More importantly for durability, the midsole acts as the boot's chassis. It provides torsional rigidity and prevents the boot from collapsing or deforming under your weight over thousands of steps. When a midsole fails, the entire boot loses its structural integrity.

Midsole Materials: The Core of Durability

The choice of material is the single most important factor in a midsole's longevity. The two most common materials represent a direct trade-off between initial comfort and long-term durability.

Polyurethane (PU): The Enduring Workhorse

Polyurethane is a dense, durable polymer that excels at resisting compression. It does not "pack out" or flatten easily over time.

This means a boot with a PU midsole will maintain its original level of support and cushioning for a significantly longer period, making it the superior choice for heavy-duty or long-term use.

EVA (Ethylene-Vinyl Acetate): The Lightweight Sprinter

EVA is a foam that is much lighter and often provides more initial "cushy" comfort than PU. It is commonly found in athletic shoes and lighter hiking boots.

However, the air trapped within EVA foam gets squeezed out with prolonged use. This causes the midsole to permanently compress, leading to a loss of both cushioning and, critically, stability.

Understanding the Trade-offs

Choosing the right boot requires understanding the compromises between different midsole materials and construction methods.

Durability vs. Weight and Initial Cost

PU midsoles are typically heavier and more expensive to produce, which can increase the boot's initial price and weight.

EVA midsoles are lighter and cheaper, making them ideal for boots where reducing weight is the primary goal, but this comes at the direct expense of the boot's usable lifespan.

The Impact of Construction

The most durable midsole is only as good as the method used to attach it. A boot with a welted construction (like a Goodyear welt) allows a cobbler to easily replace the entire outsole.

When paired with a durable PU midsole, this construction creates a boot that can be repaired and resoled for years, or even decades, of service. A compressed EVA midsole on a cemented (glued) boot often means the entire boot must be discarded.

Making the Right Choice for Your Needs

Your decision should be guided by how you intend to use the footwear and how long you expect it to last.

- If your primary focus is maximum longevity and support for heavy use: Prioritize boots with Polyurethane (PU) midsoles, ideally paired with a resolvable welt construction.

- If your primary focus is light weight and casual comfort for less frequent use: An EVA midsole is a reasonable choice, but understand that its support will degrade much more quickly.

By looking past the outsole and understanding the midsole, you can accurately judge a boot's true potential for durability.

Summary Table:

| Midsole Material | Key Characteristic | Best For | Longevity |

|---|---|---|---|

| Polyurethane (PU) | Durable, compression-resistant | Heavy-duty, long-term use | High (Years of stable support) |

| EVA Foam | Lightweight, initial comfort | Lightweight, casual use | Lower (Compresses over time) |

Need Durable Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear with a focus on long-lasting performance. We specialize in crafting boots with high-durability Polyurethane (PU) midsoles and resolvable constructions, ensuring your customers get the support and longevity they need.

We provide:

- Superior Durability: Boots built to withstand heavy use.

- Bulk Manufacturing: Reliable supply for distributors, brand owners, and bulk clients.

- Expert Craftsmanship: Quality control across all types of shoes and boots.

Let's discuss your specific needs. Contact our team today to explore production solutions that prioritize durability and value.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

People Also Ask

- Why is the implementation of low-code development platforms necessary for operations teams? Drive Factory Floor Agility

- How do interactive switching controls improve the user experience in AR footwear shopping? Boost Sales with Seamless UX

- Why is the Five-point Likert scale used for footwear purchase intentions? Mastering Data-Driven Consumer Insights

- What are the benefits of modular design for smart PPE maintenance? Optimize Longevity and Lower Maintenance Costs

- What are the core functions of the Mechanical Pseudo Foot (MPF)? Advanced Simulation for Safer Footwear Design

- What are the comprehensive production capabilities of a large-scale footwear manufacturer serving distributors and brand owners? Unlock Bulk Production Excellence

- Why is copper taffeta used for ground plane layers in plantar pressure systems? Gain Superior Data Accuracy

- How is impact attenuation tested in footwear? A Guide to Measuring Cushioning Performance