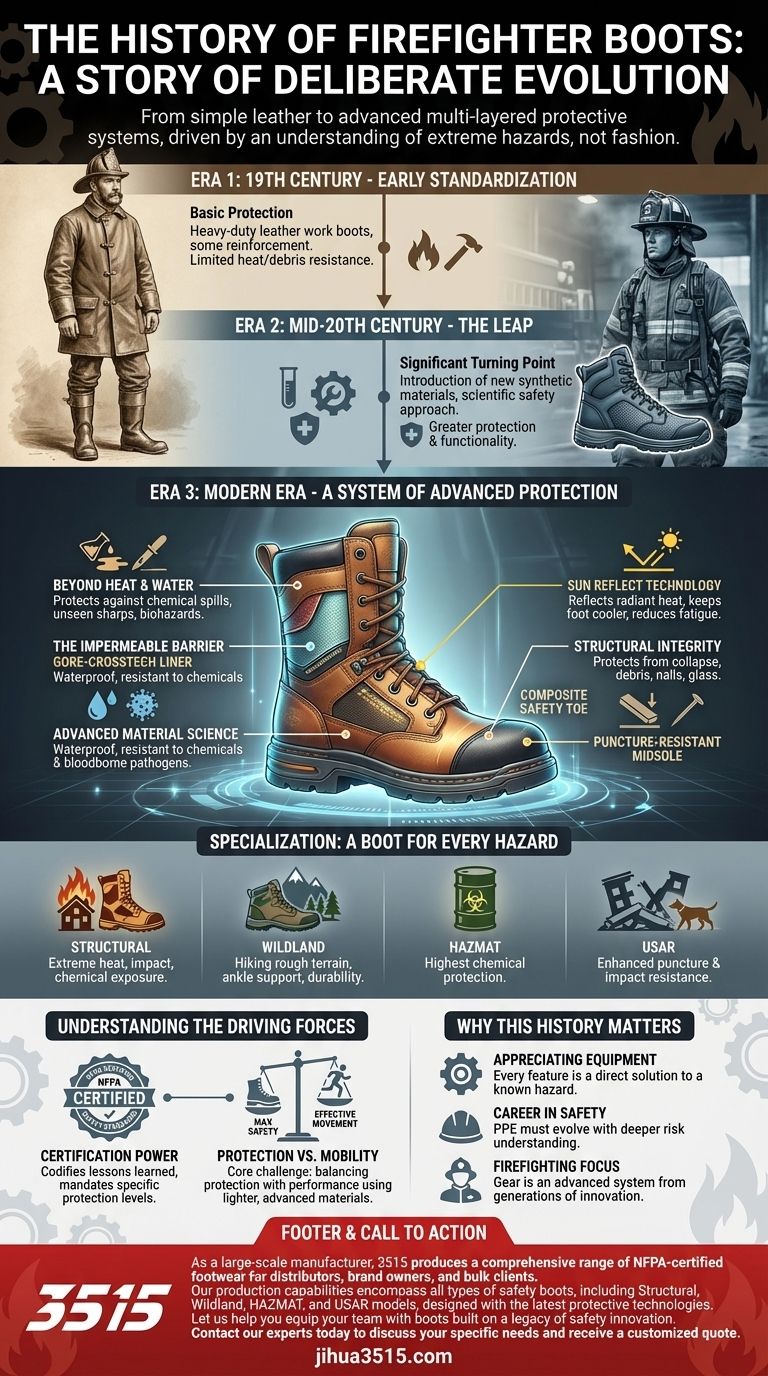

The history of the firefighter boot is a story of deliberate evolution, moving from simple reinforced leather footwear in the 19th century to the highly specialized, multi-layered protective systems used today. This progression was not driven by fashion, but by a constantly deepening understanding of the extreme and varied hazards that firefighters face, with major advancements in materials and design accelerating in the mid-20th century.

The evolution of firefighter boots is a direct reflection of our growing knowledge of risk. Each new material and design feature represents a lesson learned, creating a piece of equipment that protects not just from fire, but from the full spectrum of modern on-the-job dangers.

The Origins: From Basic Protection to Purpose-Built Gear

The journey begins when firefighting became a more organized, professional service. The gear had to evolve from general-purpose workwear into something more specific to the task.

Early Standardization (19th Century)

As municipal fire departments formed, the need for standardized equipment became obvious. The first firefighter boots were typically heavy-duty leather work boots, sometimes reinforced to offer a basic level of heat resistance and durability against rough debris.

The Mid-20th Century Leap

This period marked a significant turning point. The development of new synthetic materials, advanced manufacturing techniques, and a more scientific approach to safety allowed for boots that offered far greater protection and functionality than simple leather ever could.

The Modern Boot: A System of Advanced Protection

Today's firefighter boot is not a single item but a complex system of components, each designed to counter a specific threat—many of which go far beyond heat.

Beyond Heat and Water

While fire resistance remains critical, modern boots must protect against a host of other dangers encountered at an incident scene, including chemical spills, unseen sharp objects, and biohazards.

The Impermeable Barrier

Modern boots feature advanced liners, such as GORE-CROSSTECH. This technology creates a barrier that is not only waterproof but is also resistant to dangerous chemicals, bloodborne pathogens, and other hazardous fluids.

Advanced Material Science

The leather itself has been enhanced. Technologies like Sun Reflect are used to reflect radiant heat, keeping the leather and the firefighter's foot cooler and reducing fatigue.

Structural Integrity

To protect from collapse and debris, safety toe caps made of steel or lighter composite materials are now standard. Puncture-resistant midsoles are also essential to protect the foot from nails, glass, and other sharp objects hidden in wreckage.

Specialization: A Boot for Every Hazard

Just as the military developed specialized boots for different roles like paratroopers, firefighting has developed distinct footwear for its unique disciplines. One boot does not fit all scenarios.

Structural vs. Wildland Boots

Structural firefighting boots are built for extreme heat, impact, and chemical exposure inside a burning building. Wildland firefighting boots, in contrast, are designed for long hours of hiking over rough, uneven terrain, prioritizing ankle support and durability.

Boots for Specialized Response

The evolution continues with even more specific designs. HAZMAT boots offer the highest level of chemical protection, while USAR (Urban Search and Rescue) boots provide enhanced puncture and impact resistance for navigating collapsed structures.

Understanding the Driving Forces

The evolution of firefighter boots isn't accidental; it's guided by strict principles and standards. The primary goal is to balance extreme protection with the mobility a firefighter needs to do their job.

The Power of Certification

Modern boot design is heavily driven by certifications from safety bodies like the National Fire Protection Association (NFPA). These standards codify the lessons learned over decades, mandating specific levels of heat resistance, puncture protection, and liquid penetration.

The Trade-off: Protection vs. Mobility

The core challenge in boot design is balancing protection with performance. A heavily armored boot may offer maximum safety but be too heavy and stiff for effective movement. The historical trend has been toward using advanced, lighter materials to provide more protection without adding weight.

Why This History Matters

Understanding the evolution of firefighter boots is to understand how safety equipment adapts to meet the demands of a dangerous profession.

- If your primary focus is appreciating the equipment: Recognize that every feature on a modern boot, from the liner to the sole, is a direct solution to a known hazard discovered through experience.

- If your primary focus is a career in safety: Use the firefighter boot as a case study in how personal protective equipment must evolve in response to a deeper understanding of workplace risks.

- If your primary focus is firefighting: Trust that your gear is a highly advanced system that represents generations of innovation aimed at keeping you safe from a wide array of threats.

The history of the firefighter boot is a testament to the relentless pursuit of safety, turning hard-won lessons into life-saving technology.

Summary Table:

| Era | Key Features | Primary Materials |

|---|---|---|

| 19th Century | Basic heat/debris resistance | Reinforced leather |

| Mid-20th Century | Introduction of synthetic materials, improved safety | Advanced synthetics, rubber |

| Modern Era | NFPA certification, chemical/waterproof barriers, puncture-resistant soles | GORE-CROSSTECH liners, composite safety toes, heat-reflective leather |

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including Structural, Wildland, HAZMAT, and USAR models, designed with the latest protective technologies. Let us help you equip your team with boots built on a legacy of safety innovation. Contact our experts today to discuss your specific needs and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What materials are used in composite toe caps? Discover the Lightweight, Non-Metallic Safety Advantage

- How do damping materials in professional anti-vibration safety shoes protect the feet? High-Frequency Impact Reduction

- How does devulcanized recycled rubber benefit outsoles for safety shoes? Boost Performance and Sustainability

- What role do industrial safety shoes play in improving the labor environment? Boost Safety and Reduce Worker Stress

- What specific requirements are necessary for machinery used in the production of high-performance safety shoes?

- Why is the ASTM D790 standard used to evaluate the flexural performance of safety shoe toe cap materials? Guide to ASTM D790

- How do oilfield safety shoes provide ankle support and protection? Essential Features for Hazardous Terrain

- What safety benefits do safety shoes with electrical insulation provide? Expert Protection for Sewing Operations