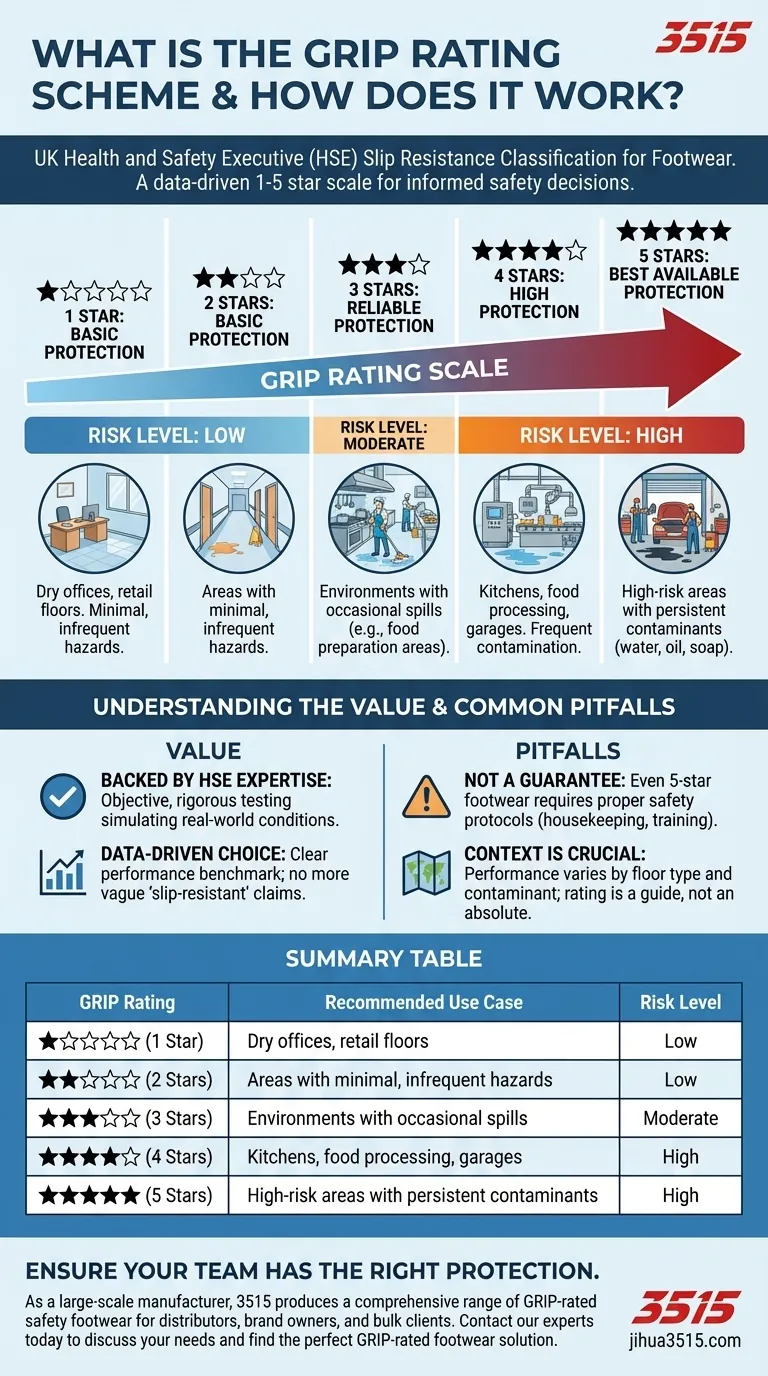

The GRIP rating scheme is a simple yet powerful system developed by the UK's Health and Safety Executive (HSE) to classify the slip resistance of footwear. It works by assigning a star rating from one to five, allowing you to quickly assess a shoe's performance in preventing slips. A higher star rating signifies a greater level of slip resistance.

The GRIP rating system translates complex safety testing into a clear 1-to-5-star scale. This empowers employers and individuals to confidently select footwear that provides the appropriate level of protection for their specific work environment.

How the GRIP System Works

The core purpose of the GRIP rating is to remove ambiguity from the term "slip-resistant." Instead of relying on marketing claims, it provides a standardized measure of performance based on HSE testing protocols.

The 1 to 5 Star Scale

The rating is straightforward: the more stars, the better the grip. This allows for an at-a-glance comparison between different types of footwear.

Low-Risk Environments (1-2 Stars)

Footwear with a one or two-star rating offers a basic level of slip resistance. It is generally suitable for environments where slip hazards are minimal and infrequent, such as dry office spaces or retail floors.

Moderate-Risk Environments (3 Stars)

A three-star rating indicates a good, reliable level of slip resistance for workplaces with occasional hazards. This might include environments where spills are possible but are cleaned up quickly.

High-Risk Environments (4-5 Stars)

Four and five-star rated footwear provides the best available protection. This is the standard you should seek for environments where slips are a common and persistent risk, such as commercial kitchens, food processing plants, or automotive garages with oily floors.

Understanding the Value of GRIP

The GRIP scheme is more than just a label; it's a critical tool for conducting a proper risk assessment and selecting the correct Personal Protective Equipment (PPE).

Moving Beyond Vague Claims

Before GRIP, a shoe was simply "slip-resistant" or not. The star rating provides a clear performance benchmark, allowing for a data-driven choice rather than a guess.

Backed by HSE Expertise

Because the system was developed by the Health and Safety Executive, you can trust that the ratings are based on objective, rigorous testing designed to simulate real-world conditions. It is an independent assessment of safety performance.

Common Pitfalls to Avoid

While the GRIP rating is an excellent tool, it's essential to understand its context and limitations to ensure maximum safety.

A Rating is Not a Guarantee

Even a five-star shoe cannot prevent all slips. The rating must be combined with proper safety protocols, including good housekeeping, "spill-aware" practices, and employee training.

Context is Crucial

The GRIP test is standardized. The performance of any footwear can vary depending on the specific type of floor surface and the nature of the contaminant (e.g., water, oil, soap, dust). The rating is a guide, not an absolute for every possible scenario.

Making the Right Choice for Your Goal

Use the GRIP rating as a key part of your safety assessment to match the footwear directly to the environmental risk.

- If your primary focus is a low-risk area with minimal spill hazards: A 1 or 2-star rating provides a baseline level of protection.

- If your primary focus is an environment with occasional or moderate slip risks: A 3-star rating offers a balanced and reliable level of safety performance.

- If your primary focus is a high-risk workplace with frequent exposure to water, oil, or other contaminants: You should only consider 4 or 5-star footwear to ensure the highest level of protection.

Ultimately, the GRIP rating system provides the clarity needed to make an informed, data-driven decision for workplace safety.

Summary Table:

| GRIP Rating | Recommended Use Case | Risk Level |

|---|---|---|

| ★☆☆☆☆ (1 Star) | Dry offices, retail floors | Low |

| ★★☆☆☆ (2 Stars) | Areas with minimal, infrequent hazards | Low |

| ★★★☆☆ (3 Stars) | Environments with occasional spills | Moderate |

| ★★★★☆ (4 Stars) | Kitchens, food processing, garages | High |

| ★★★★★ (5 Stars) | High-risk areas with persistent contaminants | High |

Ensure your team has the right protection for their specific environment.

As a large-scale manufacturer, 3515 produces a comprehensive range of GRIP-rated safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise level of slip resistance your workplace requires.

Let us help you make a data-driven safety decision. Contact our experts today to discuss your needs and find the perfect GRIP-rated footwear solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear