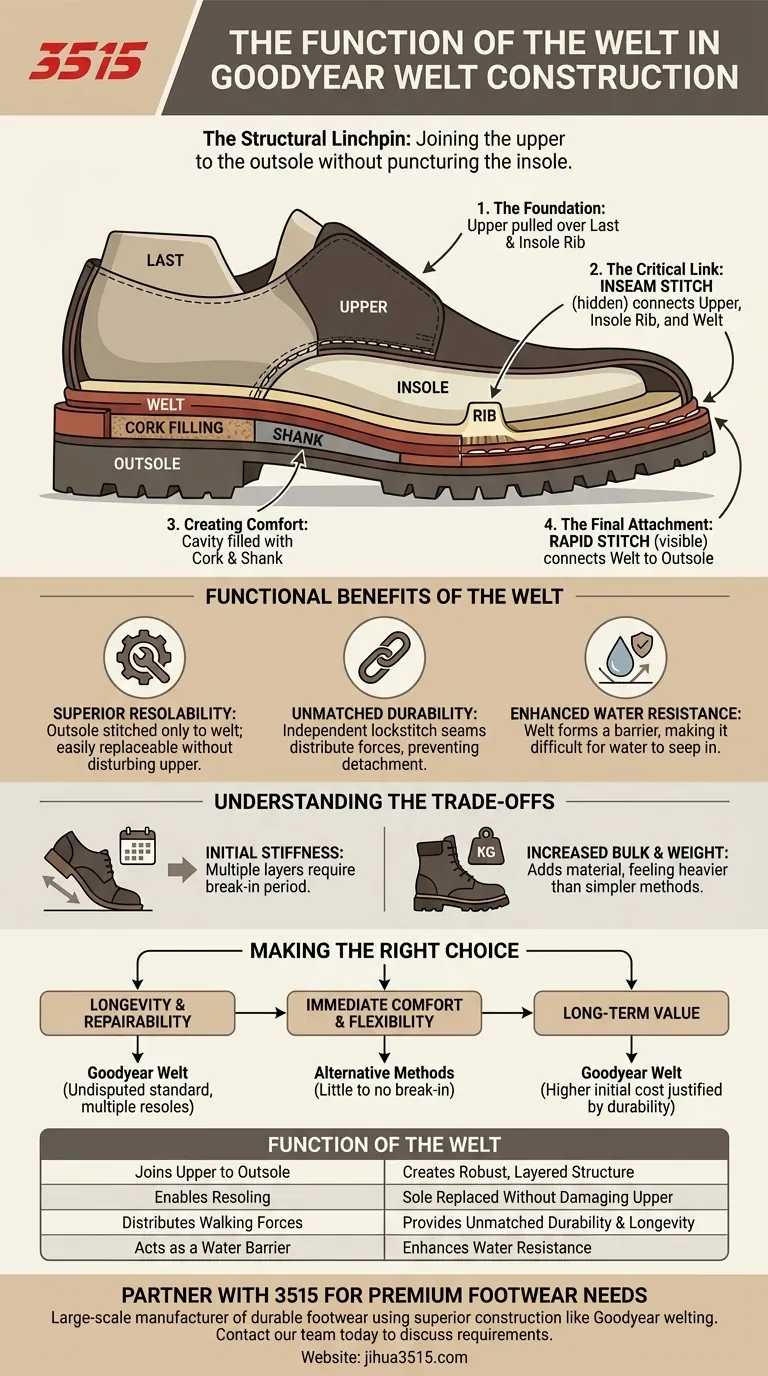

At its core, the welt is the structural linchpin of Goodyear welt construction. It is a dedicated strip of material, typically leather, that serves as the crucial intermediary component. Its primary function is to join the shoe's upper to its outsole without directly puncturing the insole, creating a uniquely durable and repairable piece of footwear.

The Goodyear welt is not merely a connector; it is the architectural foundation that makes footwear exceptionally durable, water-resistant, and, most importantly, easily resoleable without compromising the integrity of the upper.

Deconstructing the Goodyear Welt System

To truly understand the welt's function, you must see it as the central element in a multi-step engineering process. It’s what separates this premium construction method from simpler, less robust alternatives.

The Foundation: Insole and Upper

First, the leather upper is stretched and shaped over a foot-shaped model called a last. An insole, which has a perpendicular "rib" of material running around its edge, is placed inside. The upper is then pulled down and temporarily attached to this insole rib.

The Critical Link: The Inseam Stitch

This is where the welt performs its first key function. The welt is stitched through the shoe's upper and into the insole rib. This first stitch, known as the inseam, is hidden from view in the finished shoe but is structurally the most important. It creates a single, incredibly strong unit of the insole, upper, and welt.

Creating Comfort: The Cork Filling

This construction method creates a cavity between the insole and the outsole. This space is filled with a compound, most commonly granulated cork and a shank for support. This cork filling provides cushioning, insulation, and, over time, molds to the shape of your foot for a custom fit.

The Final Attachment: The Rapid Stitch

The welt's second key function is to act as a stable platform for the outsole. The outsole is attached by a second, separate stitch known as the rapid stitch. This stitch goes through the welt and the outsole, and it is the stitch you can see running along the perimeter of the sole.

The Functional Benefits of the Welt

The welt's role as an intermediary is what delivers the distinct advantages associated with this construction method. It is a deliberate, methodical approach designed for longevity.

Superior Resolability

This is the primary benefit. Because the outsole is only stitched to the welt, a cobbler can cut the rapid stitch and remove the old sole without ever disturbing the upper or the critical inseam. A new sole can then be stitched directly onto the existing welt, a process that can be repeated multiple times.

Unmatched Durability

The two independent lockstitch seams create an exceptionally strong bond. The forces of walking are distributed across the entire platform, reducing stress on any single point and preventing the sole from detaching from the upper.

Enhanced Water Resistance

The welt forms a physical barrier between the upper and the midsole, making it much more difficult for water to seep into the shoe from the ground. While not fully waterproof, it offers significantly more protection than construction methods where the upper is stitched directly through to the sole.

Understanding the Trade-offs

While revered, the Goodyear welt construction method is not without its compromises. True expertise requires acknowledging the downsides.

Initial Stiffness

The multiple layers—insole, cork, midsole, outsole—and the robust stitching result in a shoe that is often quite stiff out of the box. Goodyear-welted footwear almost always requires a break-in period for the leather and cork to soften and conform to your foot.

Increased Bulk and Weight

Compared to more streamlined methods like Blake stitching or cemented construction, a Goodyear welt adds material and layers. This can result in a shoe that feels heavier and looks chunkier, which may not be suitable for sleeker, more formal designs.

Making the Right Choice for Your Goal

Selecting footwear with this construction depends entirely on your priorities.

- If your primary focus is longevity and repairability: Goodyear welt is the undisputed standard, allowing for multiple resoles that extend the life of the footwear for decades.

- If your primary focus is immediate comfort and flexibility: You may prefer a different construction method that requires little to no break-in period.

- If your primary focus is long-term value: The higher initial cost of a Goodyear-welted shoe is often justified by its durability and the relatively low cost of resoling compared to total replacement.

Understanding the function of the welt empowers you to recognize true craftsmanship and invest in footwear that is genuinely built to last.

Summary Table:

| Function of the Welt | Key Benefit |

|---|---|

| Joins Upper to Outsole | Creates a robust, layered structure |

| Enables Resoling | Sole can be replaced without damaging the upper |

| Distributes Walking Forces | Provides unmatched durability and longevity |

| Acts as a Water Barrier | Enhances water resistance from the ground up |

Partner with 3515 for Your Premium Footwear Needs

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear using superior construction methods like Goodyear welting for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots built to last.

Let us help you deliver exceptional value and quality to your customers. Contact our team today to discuss your manufacturing requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health