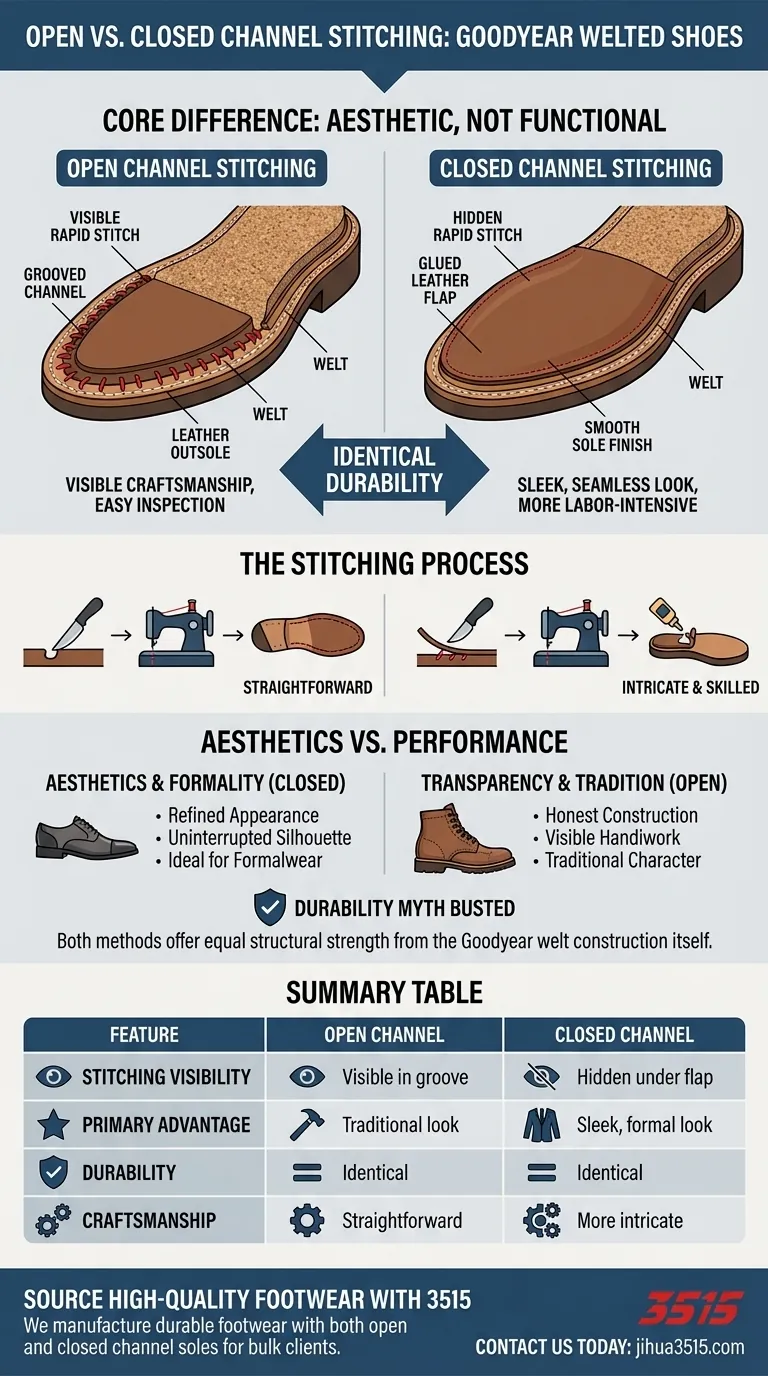

The core difference between open and closed channel stitching on a Goodyear welted shoe is purely aesthetic. An open channel leaves the outsole stitching visible in a grooved channel, while a closed channel hides the stitching under a thin, glued-down flap of the leather sole for a cleaner, seamless look. Neither method offers a functional advantage over the other in terms of durability.

When evaluating high-quality footwear, the sole's finish is a key detail. The choice between an open and closed channel sole is not about durability but about visual preference—whether you favor the clean, uninterrupted look of a hidden stitch or the traditional, visible craftsmanship of an exposed one.

A Closer Look at the Stitching Process

Understanding how each channel is created reveals why the difference is cosmetic rather than structural. Both methods are used to attach the leather outsole to the welt, which is the core of the shoe's construction.

How Open Channel Stitching Works

With an open channel, a shoemaker cuts a shallow groove or channel directly into the surface of the leather outsole. The heavy-duty rapid stitch then runs through this channel, securing the outsole to the welt.

The stitching and the channel itself remain visible on the finished shoe. This method is straightforward and allows for easy inspection of the stitch quality and density.

How Closed Channel Stitching Works

The closed channel process is more intricate. A craftsman carefully cuts a thin flap from the edge of the outsole and lifts it up, without detaching it completely.

A channel is then carved underneath this flap. The sole is stitched to the welt within this hidden channel. Finally, the leather flap is cemented back down, completely concealing the stitching and creating a flat, smooth sole surface.

The Functional Reality: Aesthetics vs. Performance

While a closed channel sole is often associated with higher-end shoes, this is a reflection of the extra labor involved, not superior construction.

The Myth of Superior Durability

There is no functional or durability advantage to a closed channel sole. The strength of the shoe comes from the Goodyear welt construction itself—the lockstitched welt, cork filling, and shank. The outsole stitch is well-protected by wear in both cases.

The Argument for Aesthetics

A closed channel sole provides an undeniably sleek and refined appearance. On a formal dress shoe, the absence of visible stitching creates a clean, uninterrupted silhouette that many find more elegant.

The Argument for Transparency

An open channel presents the shoe's construction honestly. You can see the handiwork, and a cobbler can easily assess the condition of the stitching when it's time for a resole. It imparts a traditional, functional character to the shoe.

Understanding the Practical Trade-offs

While structurally equivalent, there are minor practical points to consider between the two finishing styles.

Maintenance and Cleaning

An open channel can accumulate more dirt and debris in the exposed groove. However, this is a minor issue that is easily rectified with a few seconds of work from a shoe brush.

Cost and Craftsmanship

Because it requires more time and skill, closed channel stitching is typically found on more expensive shoes. It is often seen as a hallmark of premium craftsmanship, but its presence is just one of many details to consider when assessing a shoe's overall quality.

Making the Right Choice for Your Goal

Ultimately, the decision rests entirely on your personal preference and the shoe's intended purpose.

- If your primary focus is a sleek, formal aesthetic: Choose closed channel stitching for its seamless and refined appearance.

- If your primary focus is traditional craftsmanship and easy inspection: Choose open channel stitching for its honest, visible construction.

- If your primary focus is durability and longevity: Recognize that both methods are structurally identical, so you can base your decision purely on style.

Your choice between these two excellent finishing methods comes down to the look you wish to achieve.

Summary Table:

| Feature | Open Channel | Closed Channel |

|---|---|---|

| Stitching Visibility | Visible in a groove | Hidden under a leather flap |

| Primary Advantage | Honest, traditional look | Sleek, seamless, formal look |

| Durability | Identical to closed channel | Identical to open channel |

| Craftsmanship | Straightforward, functional | More intricate, labor-intensive |

Ready to source high-quality Goodyear welted footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those with both open and closed channel soles, ensuring you get the precise aesthetic and quality your customers demand.

Contact us today to discuss your manufacturing needs and bring your vision to life.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- Are brown dress shoes appropriate for formal events? A Guide to Choosing the Right Shoe

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence