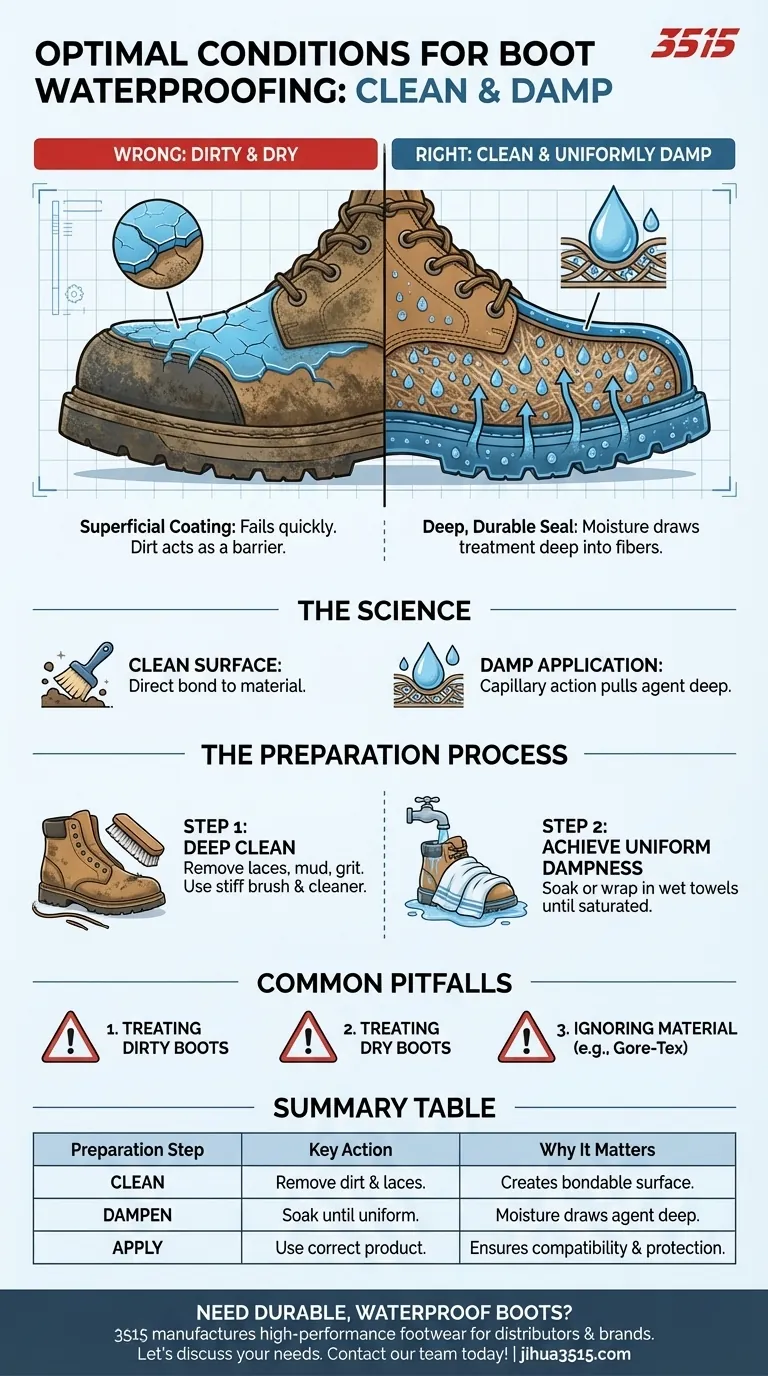

To get the best results, you should apply waterproofing treatments to boots that are thoroughly clean and uniformly damp. While applying a water-based treatment to a wet surface may seem counterintuitive, this condition is critical for the product to properly penetrate the material, ensuring a deep and durable seal rather than a superficial coating.

The core principle is simple: A clean surface allows the treatment to bond directly with the boot's material, while existing moisture within the material acts as a carrier, drawing the waterproofing agent deep into the fibers for maximum effectiveness and longevity.

Why Clean and Damp is the Gold Standard

Understanding the logic behind this preparation method ensures you won't waste time or product on an application that is destined to fail. The two conditions—clean and damp—serve distinct but equally important purposes.

The Critical Role of a Clean Surface

Dirt, dust, and grime create a physical barrier between the waterproofing treatment and the boot's exterior.

Applying a product over this layer of debris prevents it from bonding with the leather or fabric. This leads to patchy, uneven coverage and a seal that will quickly fail. A clean boot is a blank canvas.

The Science of a Damp Application

Waterproofing treatments are designed to be drawn deep into the boot's material through capillary action.

When the leather or fabric is already damp, the water present in its fibers helps pull the waterproofing agent in. Applying treatment to a completely dry boot often results in a shallow, surface-level coating that sits on top of the material and wears away quickly with use.

The Correct Preparation Process

Proper preparation is straightforward and is the single most important factor for a successful treatment. Rushing this stage will compromise the entire process.

Step 1: Perform a Deep Clean

First, remove the laces to ensure you can access the entire boot, including the tongue and eyelets.

Next, use a stiff brush to remove all caked-on mud, dust, and embedded grit. For stubborn grime, you may need to use a specialized boot cleaner and a small amount of water.

Step 2: Achieve Uniform Dampness

Once the boots are clean, you need to make them damp. You can do this by running them under a tap until the exterior is thoroughly soaked.

If your boots have dried out after cleaning, a highly effective method is to wrap them in very wet towels or rags for a couple of hours. This ensures the material is saturated evenly, which is the ideal state for application.

Common Pitfalls to Avoid

Even with the right intentions, a few common mistakes can undermine your waterproofing efforts. Being aware of them can save you significant frustration.

Mistake #1: Treating Dirty Boots

This is the most frequent error. It guarantees a weak, inconsistent waterproof seal and is essentially a waste of product. Always start with a perfectly clean surface.

Mistake #2: Treating Dry Boots

The second most common mistake is applying the treatment to bone-dry boots. This results in a weak, superficial layer that offers minimal protection and durability.

Mistake #3: Ignoring the Boot's Material

Always check the treatment's instructions. Some products are specific to full-grain leather, suede, or synthetic fabrics. Furthermore, if your boots have a waterproof/breathable membrane like Gore-Tex, you do not need to treat the fabric panels, only the leather or suede components.

A Simple Checklist for Perfect Application

Use these guidelines to match your preparation to your goal.

- If your primary focus is maximum effectiveness: Always apply waterproofing treatments to thoroughly cleaned and uniformly damp boots, never dry or dirty.

- If your boots are brand new: Do not assume they are ready. Clean off any factory residue and ensure they are damp before applying the first protective treatment.

- If your boots have a waterproof membrane: Concentrate the treatment only on the leather or suede sections and simply clean the fabric panels.

Properly preparing your boots ensures your waterproofing treatment performs exactly as intended, protecting your gear for the trail ahead.

Summary Table:

| Preparation Step | Key Action | Why It Matters |

|---|---|---|

| Clean | Remove all dirt, grime, and laces. | Creates a clean surface for the treatment to bond directly to the material. |

| Dampen | Soak boots or wrap in wet towels until uniformly damp. | Moisture draws the waterproofing agent deep into the fibers via capillary action. |

| Apply | Use the correct product for your boot's material. | Ensures compatibility and effective, long-lasting protection. |

Need Durable, Waterproof Boots for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, built to the highest standards for ultimate protection and longevity.

Let's discuss your specific needs and how we can deliver the reliable, high-quality footwear your market demands.

Contact our team today to explore partnership opportunities!

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the significance of proactive suggestions by employees? Boost Loyalty for Tactical & Sports Footwear Sales

- Why is the maintenance of tactical boots significant in professional image management? Enhance Your Elite Identity

- Why incorporate footwear geometry into contact models? Enhance Simulation Accuracy for Tactical & Sports Gear

- Why is sequential analysis utilized to evaluate tactical boots? Master Dynamic Boot Development and Ergonomic Performance

- What is the practical value of integrating orthopedic and traumatology research into the shoe last design for tactical boots and training shoes? Ensure Peak Performance & Injury Prevention.