Goodyear Welted Construction is a traditional, highly durable method for attaching the sole of a shoe to its upper. The process involves stitching a strip of leather, called the welt, to both the shoe's upper and a specific rib on the insole. The outsole is then separately stitched to this welt, creating a robust, layered structure that makes the footwear exceptionally sturdy and easy to resole.

The core principle of a Goodyear welt is separation: by stitching the outsole to the welt instead of directly to the upper, it creates a shoe that is not only more water-resistant but can be rebuilt multiple times, trading higher initial cost for a significantly longer lifespan.

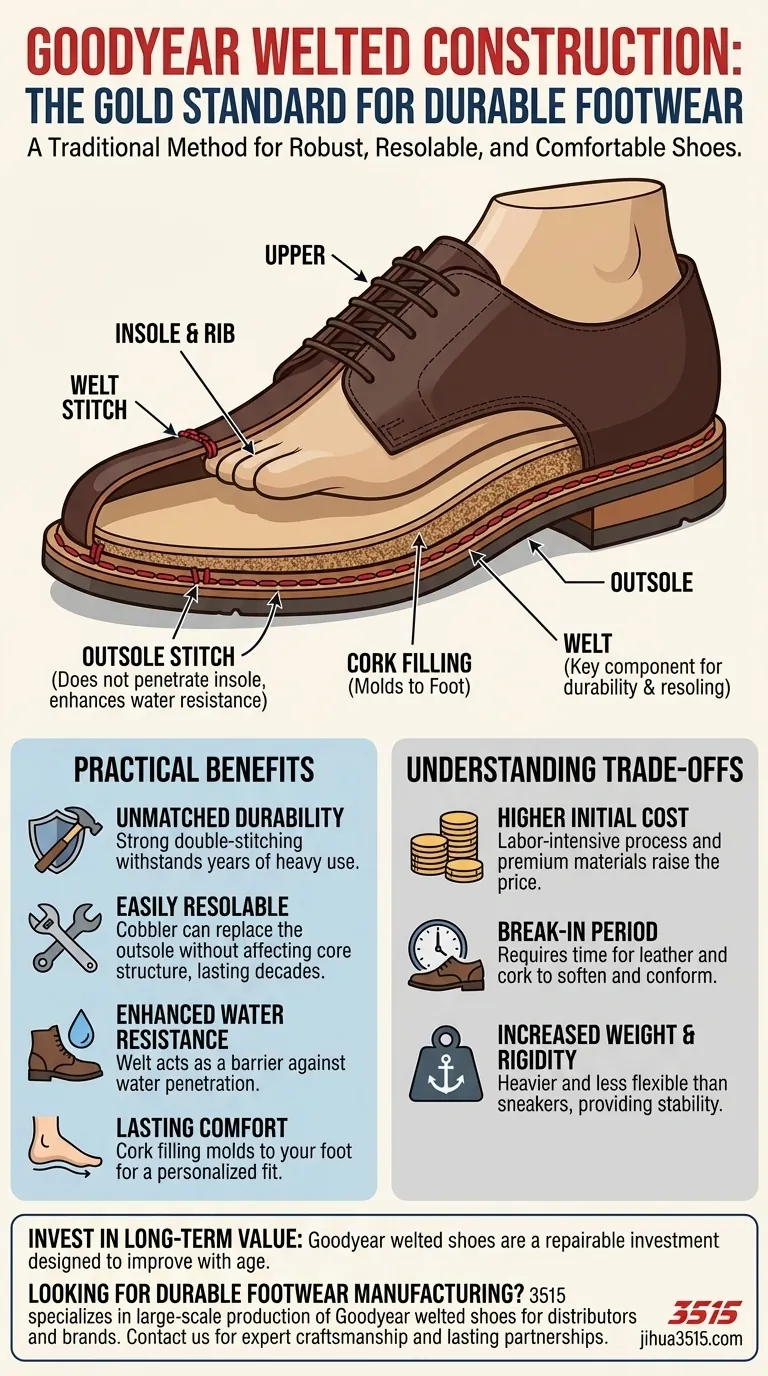

The Anatomy of a Goodyear Welt

To understand the value of this construction, it's essential to visualize its key components and how they work together. This method creates a "sandwich" of layers, each serving a distinct purpose.

The Foundation: Insole and Upper

The process begins with the shoe's upper (the main body of the shoe) being pulled over a last (a foot-shaped form). It is then attached to a canvas or leather rib that has been cemented to the insole, which sits directly under the foot.

The Key Component: The Welt

A leather strip known as the welt is then stitched through the upper and into the insole rib. This is the single most defining step of the process, creating a durable and flexible connection point that runs around the perimeter of the shoe.

The Comfort Layer: Cork Filling

The stitching of the welt creates a cavity between the insole and the outsole. This space is filled with a compound, typically granulated cork, which provides cushioning, insulation, and breathability. Over time, this cork filling molds to the shape of your foot, creating a custom-like fit.

The Final Step: Attaching the Outsole

Finally, the outsole (the part that contacts the ground) is attached. A separate, heavy-duty stitch is used to sew the outsole directly to the welt. Because this stitch does not penetrate the insole, it enhances the shoe's water resistance.

The Practical Benefits of This Construction

The intricate process of Goodyear welting delivers tangible advantages that are rarely found in more common, cemented shoe constructions.

Unmatched Durability

The double-stitching method creates an incredibly strong bond between all parts of the shoe. This construction is designed to withstand years of heavy use without the sole separating from the upper, a common failure point in lesser-quality footwear.

The Ability to Be Resoled

This is the most significant long-term benefit. Since the outsole is stitched to the welt and not the upper, a cobbler can easily remove the old sole and stitch on a new one without affecting the shoe's core structure. This allows a single pair of shoes to last for decades.

Enhanced Water Resistance

The welt acts as a buffer or barrier between the insole and the outsole. This design makes it much more difficult for water on the ground to penetrate the shoe and reach your foot compared to constructions where the upper is glued directly to the sole.

Lasting Comfort and Support

While initially stiff, Goodyear welted shoes become exceptionally comfortable over time. The cork footbed molds to the unique contours of your foot, providing personalized arch support that you cannot get from a synthetic insole.

Understanding the Trade-offs

No construction method is perfect for every situation. The robustness of a Goodyear welt comes with clear, objective compromises.

Higher Initial Cost

The Goodyear welting process is labor-intensive and requires skilled craftsmanship and higher-quality materials. This complexity inevitably results in a higher purchase price compared to mass-produced, cemented footwear.

The Break-In Period

The multiple layers of thick leather, the welt, and the sturdy stitching make the shoe quite rigid at first. A new pair requires a "break-in" period, during which the leather softens and the cork footbed begins to mold to your foot.

Increased Weight and Rigidity

The materials and construction method result in a shoe that is heavier and less flexible than a sneaker or a Blake-stitched shoe. While this provides stability, it can feel cumbersome to those accustomed to lighter footwear.

Is a Goodyear Welted Shoe Right for You?

Choosing footwear construction depends entirely on your priorities. The decision is a balance between initial investment, long-term value, and intended use.

- If your primary focus is long-term value and repairability: Goodyear welted construction is the gold standard, offering a shoe that can be rebuilt and last for decades.

- If your primary focus is immediate comfort and affordability: A cemented or sneaker-style construction will be more comfortable out of the box and cost significantly less.

- If your primary focus is a balance of durability and flexibility: You might consider other methods like Blake stitching, which offers a sleeker profile and faster break-in at the cost of some water resistance.

Ultimately, investing in a Goodyear welted shoe is an investment in a durable, repairable product designed to improve with age.

Summary Table:

| Component | Function | Benefit |

|---|---|---|

| Welt | A leather strip stitched to the upper and insole rib. | Creates a durable, water-resistant bond and allows for resoling. |

| Cork Filling | Fills the cavity between the insole and outsole. | Molds to your foot for custom comfort and provides insulation. |

| Outsole | The bottom layer, stitched to the welt. | Can be replaced multiple times, extending the shoe's lifespan for decades. |

Looking for durable, high-quality footwear for your business?

As a large-scale manufacturer, 3515 specializes in producing a comprehensive range of Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expert craftsmanship ensures unmatched durability and long-term value for your customers.

Contact us today to discuss your production needs and discover how we can build a lasting partnership.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What are the advantages and disadvantages of leather as a shoe material? Unlock Durability, Comfort & Style

- How can the flexibility of leather work boots be maximized? Achieve Lasting Comfort & Performance

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection

- What are the basic steps to clean leather work boots? A 4-Step Guide to Preserve Your Investment