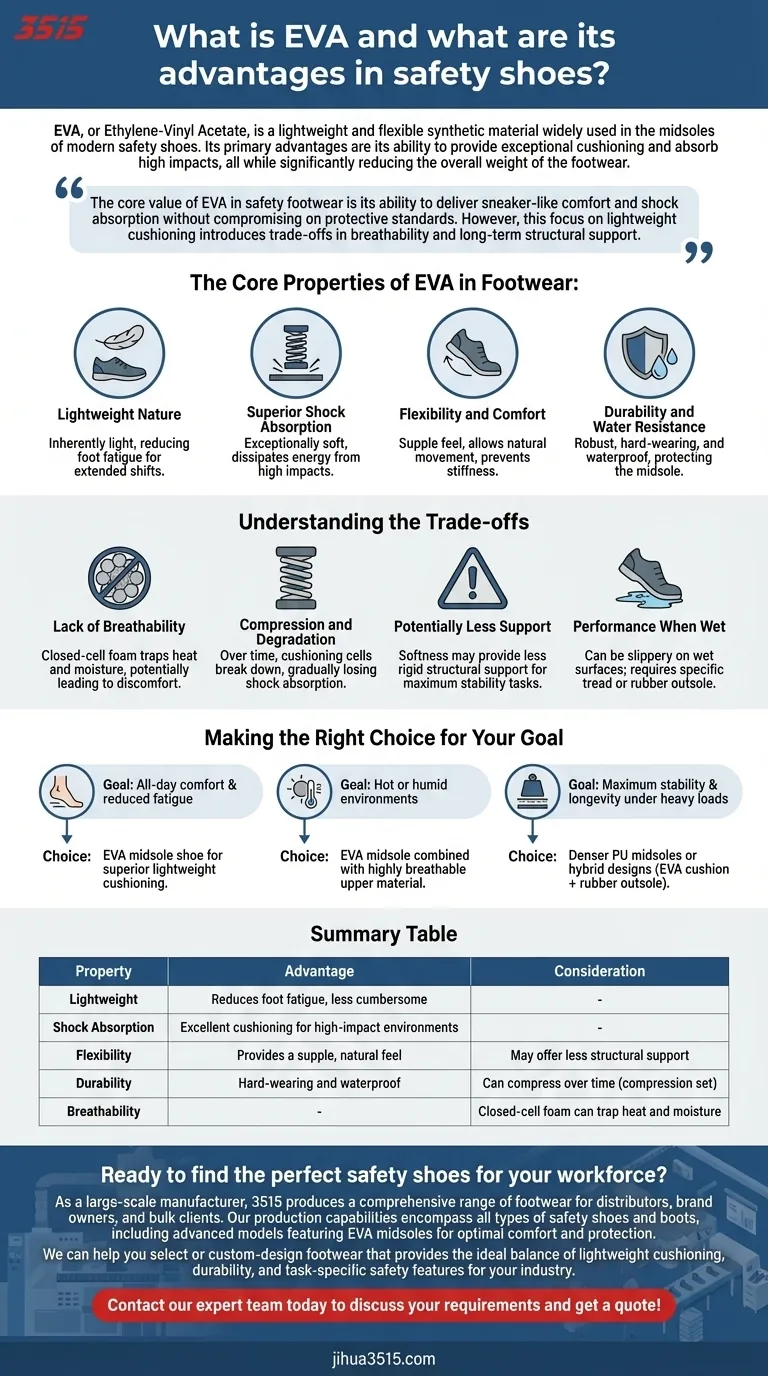

EVA, or Ethylene-Vinyl Acetate, is a lightweight and flexible synthetic material widely used in the midsoles of modern safety shoes. Its primary advantages are its ability to provide exceptional cushioning and absorb high impacts, all while significantly reducing the overall weight of the footwear.

The core value of EVA in safety footwear is its ability to deliver sneaker-like comfort and shock absorption without compromising on protective standards. However, this focus on lightweight cushioning introduces trade-offs in breathability and long-term structural support.

The Core Properties of EVA in Footwear

EVA is a foam-like plastic copolymer that has fundamentally changed expectations for comfort in the safety shoe industry. Its benefits stem directly from its unique material characteristics.

Lightweight Nature

EVA is inherently light, making shoes built with it far less cumbersome than those with traditional rubber or polyurethane (PU) soles. This directly translates to reduced foot fatigue for workers who are on their feet for extended shifts.

Superior Shock Absorption

The material is exceptionally soft and flexible, allowing it to act as a powerful shock absorber. It cushions the foot with every step, dissipating the energy from high impacts that are common in industrial and construction environments.

Flexibility and Comfort

Unlike rigid traditional materials, EVA provides a supple and comfortable feel. This flexibility allows the shoe to move more naturally with the foot, preventing the stiff and restrictive feeling associated with older safety boot designs.

Durability and Water Resistance

EVA is a robust, hard-wearing material that is also waterproof. This quality helps protect the integrity of the shoe's midsole and shields the wearer's foot from external moisture.

Understanding the Trade-offs

While EVA offers significant advantages, its properties also introduce certain limitations that are critical to understand when selecting safety footwear.

Lack of Breathability

EVA is a closed-cell foam, meaning it does not allow air to pass through it. This lack of air exchange can trap heat and moisture inside the shoe, potentially leading to increased humidity, discomfort, and odors over a long day.

Compression and Degradation

Over time and with repeated impact, the cushioning cells within the EVA can break down and compress. This "compression set" means the material may gradually lose some of its shock-absorbing capability and supportive structure.

Potentially Less Support

The same softness that makes EVA comfortable can also mean it provides less rigid structural support than denser materials. For tasks requiring maximum ankle stability or protection against torsion, a shoe with only an EVA sole might be insufficient.

Performance When Wet

Depending on the outsole design paired with it, the inherent properties of some EVA compounds can make them slippery on wet surfaces. The tread pattern and use of other materials like rubber are crucial for mitigating this risk.

Making the Right Choice for Your Goal

Selecting the appropriate safety shoe depends on balancing the benefits of EVA with the specific demands of your work environment.

- If your primary focus is all-day comfort and reducing fatigue: A shoe with an EVA midsole is an outstanding choice due to its superior lightweight cushioning.

- If you work in hot or humid environments: Seek out footwear that combines an EVA midsole with a highly breathable upper material to help manage internal moisture.

- If your primary focus is maximum stability and longevity under heavy loads: Consider shoes with denser polyurethane (PU) midsoles or hybrid designs that use EVA for cushioning but rubber for a durable, high-traction outsole.

Ultimately, understanding the role of EVA allows you to choose safety footwear that provides the right blend of modern comfort and task-specific protection.

Summary Table:

| Property | Advantage | Consideration |

|---|---|---|

| Lightweight | Reduces foot fatigue, less cumbersome | - |

| Shock Absorption | Excellent cushioning for high-impact environments | - |

| Flexibility | Provides a supple, natural feel | May offer less structural support |

| Durability | Hard-wearing and waterproof | Can compress over time (compression set) |

| Breathability | - | Closed-cell foam can trap heat and moisture |

Ready to find the perfect safety shoes for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including advanced models featuring EVA midsoles for optimal comfort and protection.

We can help you select or custom-design footwear that provides the ideal balance of lightweight cushioning, durability, and task-specific safety features for your industry.

Contact our expert team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals