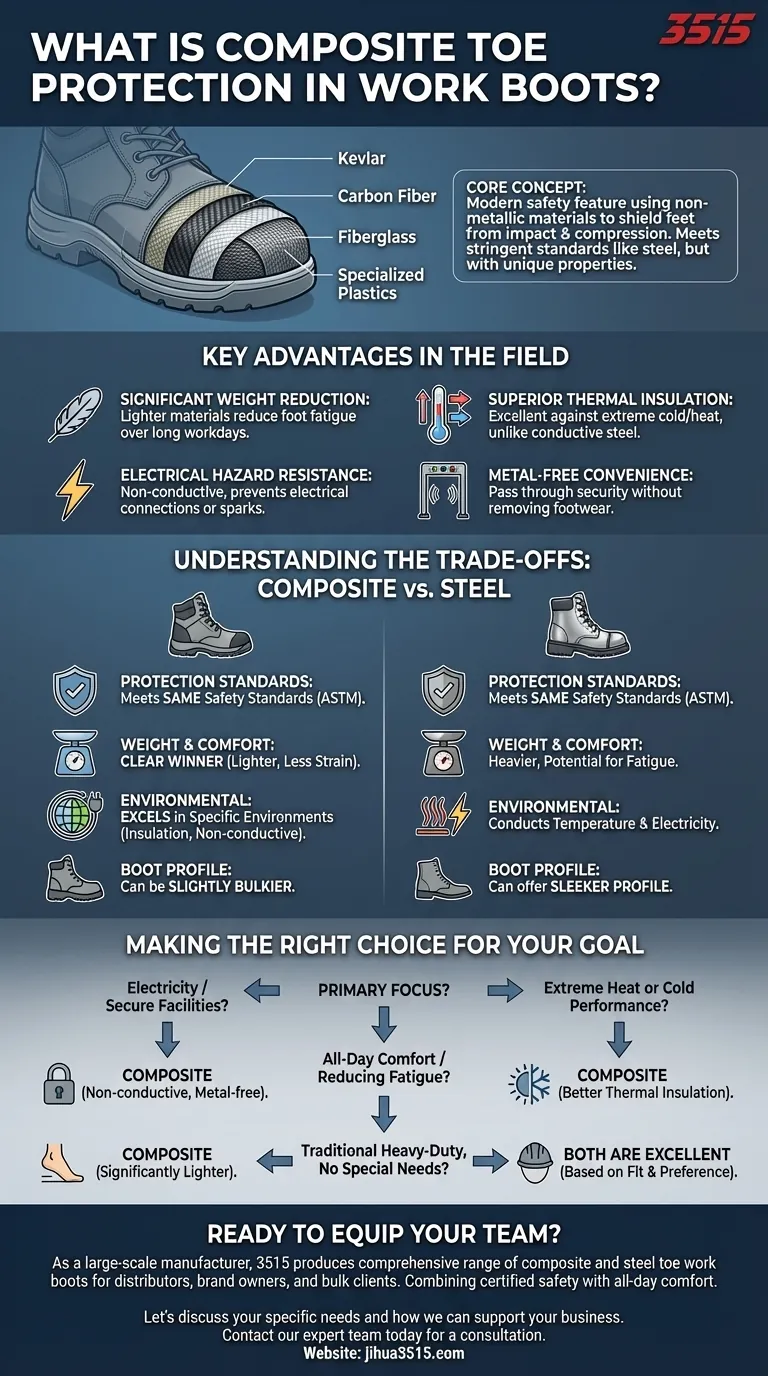

At its core, composite toe protection is a modern safety feature in work boots that uses non-metallic materials to shield your feet from impact and compression. Unlike traditional steel toes, these protective caps are crafted from a blend of materials including Kevlar, carbon fiber, fiberglass, and specialized plastics. They are engineered to meet the same stringent safety standards as steel but offer a unique set of properties suited for specific work environments.

The decision between composite and steel toe boots is not about which is fundamentally "safer"—both are rated for the same level of protection. The real choice depends entirely on your work environment and whether you prioritize lightweight comfort, thermal insulation, and metal-free properties over the traditional profile of steel.

The Core Components of Composite Protection

What Are They Made Of?

Composite toe caps are built from advanced, non-metallic materials. The most common components include Kevlar, carbon fiber, fiberglass, and high-density plastics.

Each of these materials is chosen for its high strength-to-weight ratio and its ability to provide structural integrity against hazards. This non-metallic construction is the source of all their primary benefits.

How They Ensure Safety

Composite toe boots provide high-level protection against crushing, cutting, and puncture hazards. They are tested and certified to meet the same safety requirements (such as ASTM standards) as their steel counterparts.

The layered, rigid structure of the composite materials dissipates the force from an impact across the entire cap, protecting the wearer's foot. This makes them a trusted choice in demanding industries like construction, forestry, and law enforcement.

Key Advantages in the Field

Significant Weight Reduction

The most noticeable benefit of composite toe boots is their lighter weight. By eliminating steel, these boots can significantly reduce foot fatigue over a long workday, a crucial factor for anyone who spends hours on their feet.

Superior Thermal Insulation

Because composite materials do not conduct temperature effectively, they provide excellent insulation. In extreme cold or heat, your feet remain more comfortable as the cap doesn't transfer the outside temperature, unlike a steel toe which can become very cold or hot.

Electrical Hazard Resistance

The non-metallic nature of composite toes makes them ideal for electricians or anyone working in environments with live electrical hazards. They are non-conductive and prevent the risk of creating an electrical connection or spark.

Metal-Free Convenience

For professionals working in secure facilities like airports, power plants, or government buildings, composite toe boots offer a major advantage. They allow you to pass through metal detectors without the hassle of removing your footwear.

Understanding the Trade-offs: Composite vs. Steel

While composite technology offers many modern benefits, it's essential to understand how it compares directly to the industry standard, steel.

Protection Standards

This is a critical point: both meet the same safety standards. A certified composite toe boot and a certified steel toe boot will provide the same baseline level of protection against impact and compression. One is not inherently safer than the other.

Weight and All-Day Comfort

Composite is the clear winner here. The lighter materials directly translate to less strain and fatigue, making them a superior choice for comfort during long shifts, especially those involving extensive walking or climbing.

Environmental Performance

Composite excels in specific environments. Its thermal insulation is better for extreme temperatures, and its non-conductive properties are a non-negotiable requirement for many electrical jobs. Steel conducts both temperature and electricity.

Boot Profile and Bulk

To achieve the same strength rating as steel, a composite cap may sometimes be slightly bulkier. While this is a minor design consideration, some users may find that traditional steel toe boots offer a slightly lower or sleeker profile.

Making the Right Choice for Your Goal

Selecting the proper foot protection requires matching the boot's features to the demands of your job.

- If your primary focus is working around electricity or in secure facilities: Composite is the definitive choice due to its non-conductive, metal-free construction.

- If your primary focus is all-day comfort and reducing fatigue: The significantly lighter weight of composite boots will make a tangible difference over long shifts.

- If your primary focus is performance in extreme heat or cold: Composite provides far better thermal insulation, keeping your feet comfortable when steel would not.

- If your primary focus is traditional heavy-duty work with no special environmental needs: Both steel and composite are excellent options, so your choice may come down to specific boot fit and personal preference.

Ultimately, understanding these material differences empowers you to select safety footwear based on the real-world demands of your job, not just tradition.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Material | Kevlar, Carbon Fiber, Plastics | Steel |

| Weight | Lighter | Heavier |

| Thermal Insulation | Excellent (Non-conductive) | Poor (Conductive) |

| Electrical Hazard | Non-conductive (Safer) | Conductive |

| Metal Detector Safe | Yes | No |

| Safety Standards | Meets ASTM Standards (Same as Steel) | Meets ASTM Standards |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite toe and steel toe work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right footwear—combining certified safety with all-day comfort—for any work environment.

Let's discuss your specific needs and how we can support your business.

Contact our expert team today for a consultation

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- What is the purpose of steel-toe moc toe boots? Achieve All-Day Safety and Comfort

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety