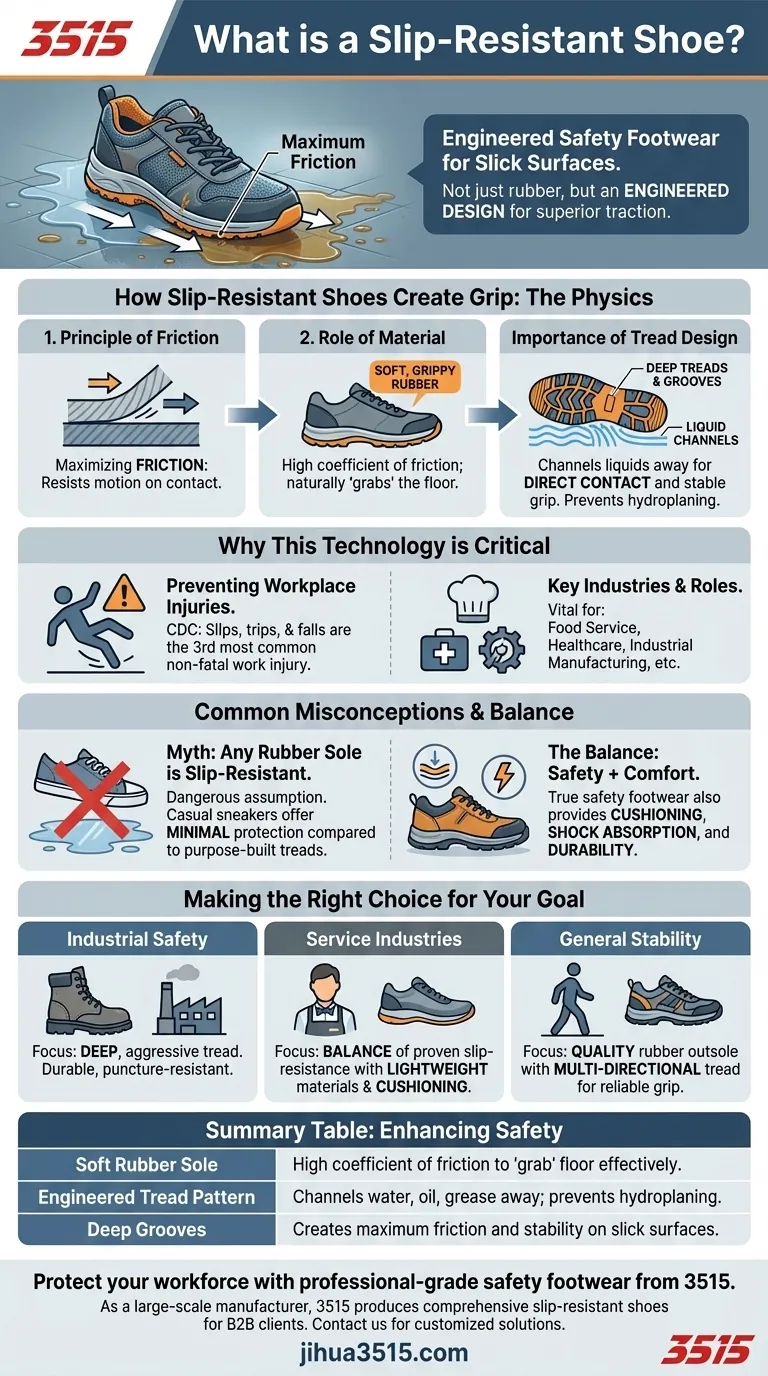

At its core, a slip-resistant shoe is a piece of safety footwear specifically engineered to prevent slips and falls on slick surfaces like wet, oily, or greasy floors. Unlike standard footwear, these shoes feature outsoles made of soft, grippy rubber with a distinct tread pattern designed to create maximum friction and channel liquids away from the point of contact.

The critical difference is not simply the rubber material, but the engineered design of the sole's tread pattern. This design is what provides superior traction and prevents the wearer from losing their footing on hazardous surfaces.

How Slip-Resistant Shoes Create Grip

To understand why these shoes are effective, it's essential to look at the physics of their design. Their protective capability comes from a combination of material science and intelligent engineering.

The Principle of Friction

Slip-resistant shoes work by maximizing friction, which is the force that resists motion when two surfaces rub against each other. The higher the friction between the shoe's sole and the floor, the less likely you are to slip.

The Role of the Material

These shoes almost always use a soft, synthetic rubber for the outsole. This material has a high coefficient of friction, meaning it naturally "grabs" the floor surface more effectively than the harder plastics or leather found on typical shoes.

The Importance of Tread Design

This is the most crucial element. A flat rubber sole would be ineffective on wet surfaces because a thin layer of liquid would cause hydroplaning.

The deep treads and grooves in a slip-resistant sole are designed to channel water, oil, and other liquids out from under the shoe. This allows the rubber to make direct contact with the solid ground, ensuring a firm and stable grip.

Why This Technology is Critical

In many professional environments, slip-resistant footwear is not just a recommendation; it's a fundamental piece of personal protective equipment (PPE) that prevents serious injury.

Preventing Workplace Injuries

According to the CDC, slips, trips, and falls are the third most common cause of non-fatal work-related injuries. These incidents can lead to significant pain, lost work time, and high costs for both employees and employers.

Key Industries and Roles

Slip-resistant shoes are vital for workers in industries where floors are frequently slick. This includes professionals in food service, healthcare, and industrial manufacturing, as well as utility workers, construction crews, and delivery personnel.

Common Misconceptions to Avoid

Trusting the wrong footwear can lead to a false sense of security. It's important to understand what a slip-resistant shoe is—and what it isn't.

Myth: Any Rubber Sole is Slip-Resistant

This is a dangerous assumption. While all slip-resistant shoes have rubber soles, not all rubber-soled shoes are slip-resistant. A casual sneaker with a flat rubber sole offers minimal protection on a greasy floor compared to a work shoe with a purpose-built tread pattern.

The Balance with Other Features

True safety footwear must do more than just prevent slips. A quality work shoe balances its specialized outsole with other critical features like cushioning for all-day comfort, shock absorption, and durable construction suitable for the specific work environment.

Making the Right Choice for Your Goal

Selecting the right shoe depends entirely on the environment where you will be wearing it.

- If your primary focus is safety in industrial settings: Prioritize shoes with deep, aggressive tread patterns and durable, puncture-resistant construction.

- If your primary focus is all-day wear in service industries: Look for a balance of proven slip-resistance with lightweight materials and significant cushioning to reduce fatigue.

- If your primary focus is general stability for daily activities: Choose a versatile shoe with a quality rubber outsole that features a noticeable, multi-directional tread pattern for reliable grip.

Investing in the right footwear is a direct investment in your personal safety and stability.

Summary Table:

| Feature | How It Enhances Safety |

|---|---|

| Soft Rubber Sole | Provides a high coefficient of friction to "grab" the floor surface effectively. |

| Engineered Tread Pattern | Channels water, oil, and grease away to prevent hydroplaning and ensure direct contact with the ground. |

| Deep Grooves | Creates maximum friction and stability on slick surfaces, preventing slips and falls. |

Protect your workforce with professional-grade safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our footwear combines advanced grip technology with all-day comfort and durability, tailored for industries like food service, healthcare, and industrial manufacturing.

Contact us today to discuss your safety footwear needs and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene