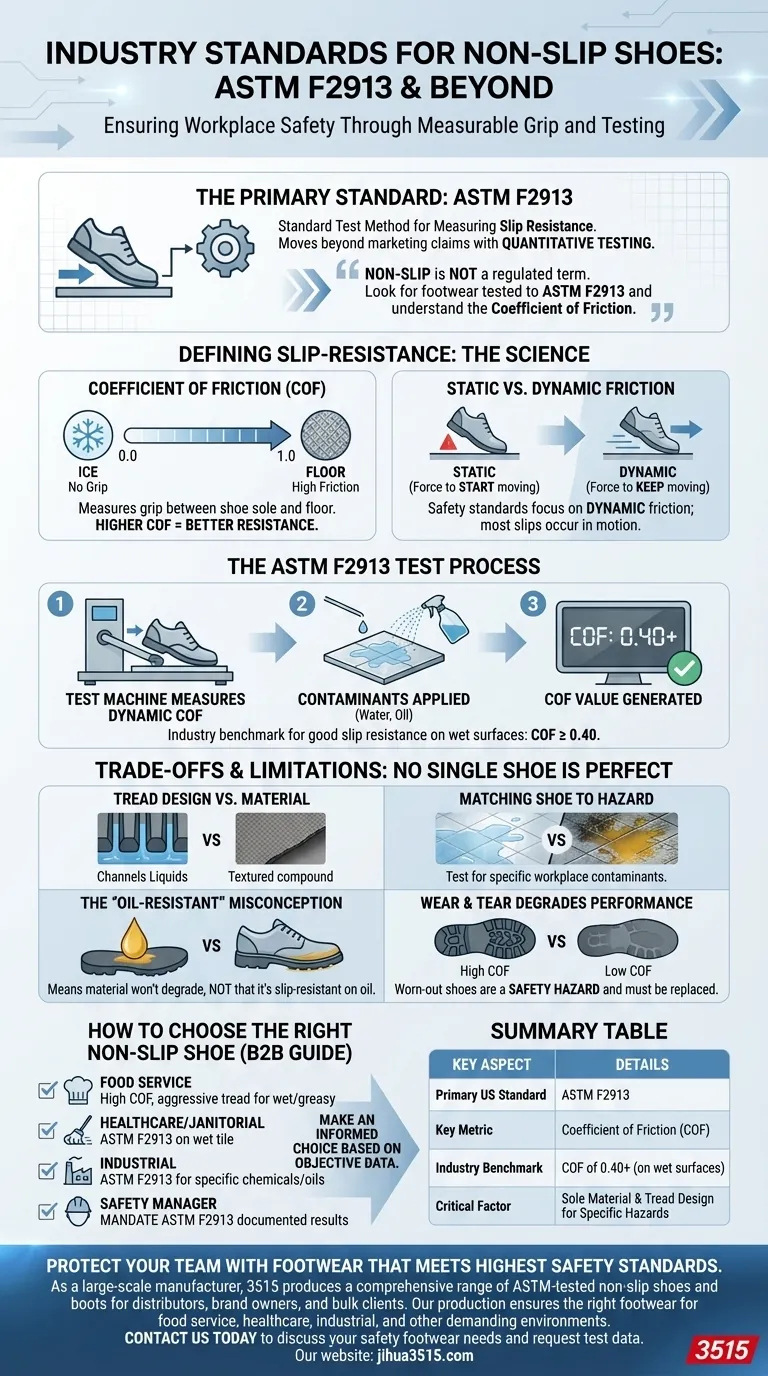

The primary industry standard for non-slip footwear in the United States is ASTM F2913. This standard specifies the test method for measuring the slip resistance of footwear on various surfaces. A shoe that complies with this standard has undergone quantitative testing to prove its grip, moving beyond simple marketing claims to provide a measurable level of safety.

The term "non-slip" is not a regulated marketing term. To ensure true safety, you must look for footwear that has been tested according to a recognized standard like ASTM F2913 and understand what its performance rating, or Coefficient of Friction, actually means for your specific work environment.

What Does "Slip-Resistant" Mean Technically?

A truly slip-resistant shoe is defined by its performance in a controlled test, not by its name or description. Understanding the science behind this is key to making a safe choice.

The Coefficient of Friction (COF)

The core concept behind slip resistance is the Coefficient of Friction (COF). This is a simple number that measures the amount of grip between two surfaces—in this case, the shoe's sole and the floor.

A higher COF value means more grip and better slip resistance. A COF of 0.0 would be like ice on ice, while a COF of 1.0 would be extremely high friction.

Static vs. Dynamic Friction

Friction is measured in two states. Static friction is the force needed to start an object moving from a standstill. Dynamic friction (or kinetic friction) is the force needed to keep it moving.

Safety standards focus on dynamic friction because most slip-and-fall accidents happen while a person is already in motion.

The Key Standard: ASTM F2913

For workplace safety in the United States, the ASTM F2913 standard is the most important benchmark. It provides a reliable and repeatable method for testing shoe safety.

The US Benchmark for Safety

ASTM F2913 is the "Standard Test Method for Measuring Frictional Properties of Shoe Outsole and Floor Surface Materials." It is the definitive procedure used to certify footwear as slip-resistant.

How the Test Works

The test uses a specialized machine to measure the dynamic COF. The shoe is placed on a common flooring surface (like vinyl tile), which is then wetted with a contaminant like water or oil. The machine measures the force required to make the shoe slip.

Understanding the COF Results

The result of the test is a COF value. While there is no universal "pass/fail" number, a common industry benchmark for good slip resistance on a wet surface is a COF of 0.40 or higher. Reputable manufacturers will often provide these test results for their footwear.

Understanding the Trade-offs and Limitations

Achieving a high slip-resistance rating involves design choices, and no single shoe is perfect for every hazardous environment.

Tread Design vs. Material Compound

The ASTM test primarily measures the grip of the sole's material compound. However, the tread pattern is equally critical. Deep, well-spaced treads are designed to channel water, oil, and other liquids away from the contact points, preventing hydroplaning.

Matching the Shoe to the Hazard

A shoe that earns a high COF on a wet tile floor may not perform as well on a greasy, oily, or dusty surface. It is critical to select footwear tested for the specific contaminants present in your workplace.

The "Oil-Resistant" Misconception

The term "oil-resistant" means the shoe's sole material will not break down or degrade when exposed to petroleum products. It does not automatically mean the shoe is slip-resistant on an oily surface. You must look for both properties if you work with oils.

Wear and Tear Degrades Performance

The slip-resistant properties of a shoe are highest when it's new. As the tread wears down, the COF decreases significantly. Worn-out shoes are a safety hazard and must be replaced.

How to Choose the Right Non-Slip Shoe

Use these guidelines to translate standards into an effective purchasing decision.

- If your primary focus is food service or a commercial kitchen: Seek shoes with a high COF (above 0.40) specifically tested on wet and greasy surfaces, featuring an aggressive tread to channel liquids.

- If your primary focus is healthcare or janitorial work: Prioritize shoes proven to perform well on smooth, wet surfaces like tile, and verify they have an ASTM F2913 certification.

- If your primary focus is industrial or manufacturing: Look for footwear that meets the ASTM standard and also specifies resistance to the particular chemicals or oils present in your facility.

- If you are a safety manager: Do not accept generic "slip-resistant" claims. Mandate that all safety footwear comes with documented test results from the ASTM F2913 standard.

Making an informed choice based on objective data is the most reliable way to ensure workplace safety.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary US Standard | ASTM F2913 |

| Key Metric | Coefficient of Friction (COF) |

| Industry Benchmark | COF of 0.40 or higher (on wet surfaces) |

| Critical Factor | Sole material & tread design for specific hazards |

Protect your team with footwear that meets the highest safety standards. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-tested non-slip shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right footwear for food service, healthcare, industrial, and other demanding environments. Contact us today to discuss your safety footwear needs and request test data.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime