At its core, the requirement for slip-resistant shoes is driven by workplace environments where floors are frequently contaminated with water, oil, grease, or other slick substances. The most common industries mandating this protection include food service, healthcare, manufacturing, and construction, where the risk of slips and falls is a constant operational hazard.

The specific industry is less important than the environmental reality. Any job that involves walking on surfaces prone to being wet, oily, or otherwise slippery demands the use of properly certified slip-resistant footwear to ensure worker safety.

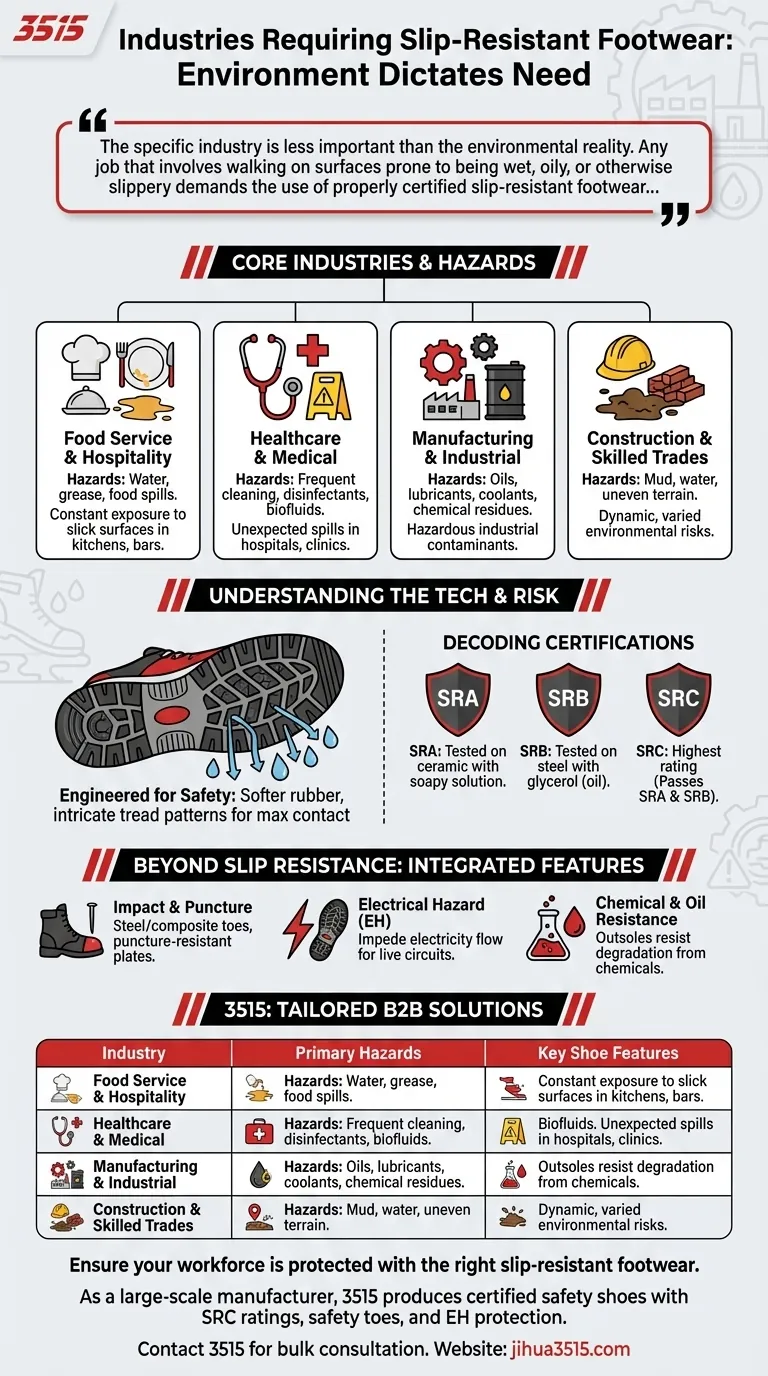

The Core Industries Requiring Slip Resistance

While any workplace can have slippery floors, certain industries face this challenge as a daily, unavoidable part of the job. The need for protection is a direct result of the materials and processes involved in their work.

Food Service & Hospitality

Workers in restaurants, commercial kitchens, and bars are constantly exposed to a combination of water, grease, and food spills. These substances create predictably dangerous walking surfaces, making high-traction footwear an absolute necessity.

Healthcare & Medical Facilities

Hospitals, clinics, and long-term care facilities present a unique risk. Floors are frequently mopped and disinfected, and unexpected spills from medical materials or patient care can occur without warning, requiring reliable footwear for all staff.

Manufacturing & Industrial Work

Factory floors are often coated in oils, lubricants, coolants, and chemical residues from machinery and production processes. These industrial contaminants are particularly hazardous, demanding shoes with specialized, resistant outsoles.

Construction & Skilled Trades

Construction sites are dynamic environments with exposure to mud, water, and uneven, slick surfaces. Workers from general laborers to specialized trades like plumbers and linemen need protection from these varied slip hazards.

Understanding the True Risk Factor

Simply knowing the industry isn't enough. A deeper understanding of the specific hazards and the technology designed to counter them is crucial for ensuring true workplace safety.

The Hazard Dictates the Need

The defining factor is the presence of a contaminant on the walking surface. A retail stockroom with a leaking freezer, an auto mechanic's garage, or a utility worker's route in the rain all create the same fundamental need for slip-resistant soles.

What Makes a Shoe "Slip-Resistant"?

True slip-resistant shoes are engineered for safety. They feature softer rubber compounds that grip surfaces more effectively and have intricate tread patterns designed to channel liquids away from the bottom of the shoe, maximizing contact between the sole and the floor.

Decoding Safety Certifications

Official ratings provide objective proof of performance. Look for these common European standards, which are widely recognized globally:

- SRA: Tested and passed for slip resistance on a ceramic tile floor wetted with a soapy solution.

- SRB: Tested and passed for slip resistance on a smooth steel floor with glycerol (oil).

- SRC: The highest rating, indicating the shoe has passed both SRA and SRB test conditions.

Evaluating Trade-offs and Additional Features

Slip resistance is often the starting point for safety footwear, not the end. The specific job role frequently dictates the need for other protective qualities, creating a balance of features.

Slip Resistance is Only the Beginning

In many hazardous jobs, slips are just one of several potential dangers. The most effective work shoes bundle slip resistance with other critical safety features tailored to the environment.

Impact and Puncture Protection

For construction, manufacturing, and logistics workers, protection from falling objects or sharp debris is paramount. This requires integrating steel toes, composite safety toes, and puncture-resistant plates into the shoe's design.

Electrical Hazard (EH) Protection

Electricians, linemen, and industrial maintenance workers require shoes with Electrical Hazard (EH) rated soles. These are designed to impede the flow of electricity, providing a secondary source of protection from live circuits.

Chemical and Oil Resistance

In industrial or automotive settings, the outsole material itself must resist degradation from chemicals and oils. A sole that breaks down when exposed to these substances will quickly lose its slip-resistant properties and structural integrity.

Making the Right Choice for Your Goal

Selecting the correct footwear involves matching the shoe's certified features to the specific, known hazards of your work environment.

- If your primary focus is wet or greasy service environments: Prioritize an SRC slip-resistance rating and an upper material that is easy to clean and resists oil saturation.

- If your primary focus is construction or heavy industry: Combine an SRC rating with a certified safety toe (steel or composite) and puncture-resistant soles.

- If your primary focus is healthcare or clean indoor work: A shoe with an SRA or SRC rating and a fluid-resistant, non-marking sole is the ideal choice.

- If your primary focus is work around live electricity: Ensure your slip-resistant footwear carries a specific Electrical Hazard (EH) rating.

Ultimately, choosing the right shoe is a critical risk assessment that protects you by neutralizing the specific dangers of your workplace floor.

Summary Table:

| Industry | Primary Hazards | Key Shoe Features |

|---|---|---|

| Food Service & Hospitality | Water, grease, food spills | SRC rating, easy-clean uppers |

| Healthcare & Medical | Wet, disinfected floors | SRA/SRC rating, fluid-resistant, non-marking |

| Manufacturing & Industrial | Oils, lubricants, chemicals | SRC rating, safety toe, chemical-resistant sole |

| Construction & Skilled Trades | Mud, water, uneven surfaces | SRC rating, safety toe, puncture-resistant sole |

Ensure your workforce is protected with the right slip-resistant footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We combine SRC-rated slip resistance with critical features like safety toes, puncture protection, and EH ratings to meet the specific demands of your industry.

Let us help you mitigate workplace risks with durable, high-performance footwear tailored to your needs.

Contact 3515 today for a consultation to discuss your requirements and explore our production capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job