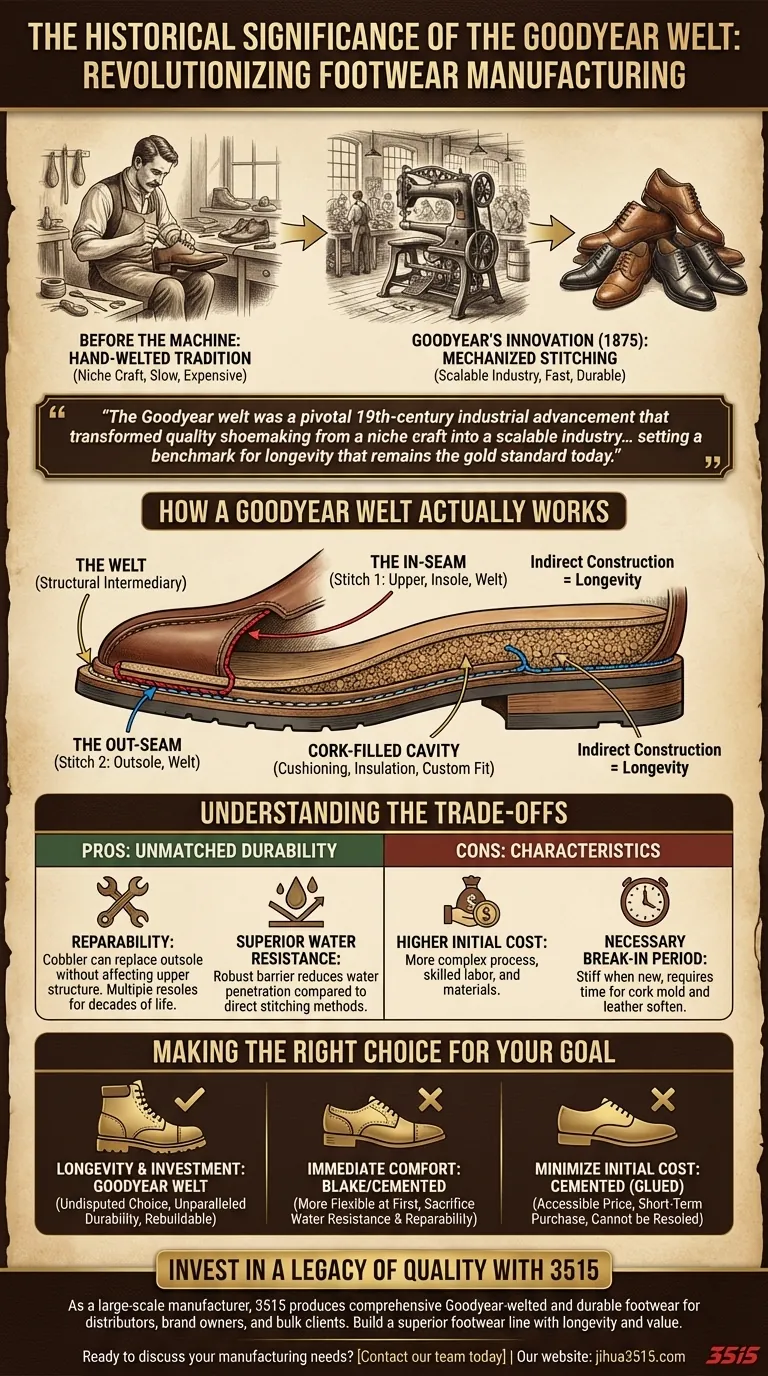

The historical significance of the Goodyear welt is its role in revolutionizing footwear manufacturing. Patented by Charles Goodyear Jr. in the 1870s, the invention of a specialized stitching machine mechanized a previously laborious hand-sewn process. This innovation dramatically increased the efficiency and durability of shoe production, establishing a new global standard for high-quality, long-lasting, and repairable footwear.

The Goodyear welt was a pivotal 19th-century industrial advancement that transformed quality shoemaking from a niche craft into a scalable industry. It democratized access to durable, resoleable shoes, setting a benchmark for longevity that remains the gold standard today.

The Dawn of a Shoemaking Revolution

To understand the impact of the Goodyear welt, you must first understand the world it entered. It wasn't just a new technique; it was a fundamental shift in how quality goods were made.

Before the Machine: The Hand-Welted Tradition

For centuries, the most durable shoes were "hand-welted." A master craftsman would painstakingly sew the shoe's upper, insole, and a leather strip (the welt) together by hand. This was an incredibly slow, skilled, and expensive process, limiting high-quality footwear to the wealthy.

Charles Goodyear Jr.'s Innovation

The machine patented by Charles Goodyear Jr. around 1875 mechanized this critical step. It could perform the complex lockstitch needed to attach the welt far faster and more consistently than any human hand. This single invention broke the primary bottleneck in producing durable footwear.

From Niche Craft to Industry Standard

This mechanization allowed for the mass production of shoes with the same structural integrity as their handmade predecessors. Suddenly, exceptionally durable and repairable boots and shoes became accessible to a much broader market, cementing the Goodyear welt as the definitive construction method for quality work and dress footwear.

How a Goodyear Welt Actually Works

The genius of the Goodyear welt lies in its indirect construction. Unlike cheaper methods, the outsole is never directly attached to the upper, which is the key to its longevity.

The Welt: A Structural Intermediary

The welt is a sturdy strip of leather stitched around the perimeter of the shoe. It acts as a connecting platform between the shoe's upper and the outsole.

The Two-Level Stitch

Two independent stitches are used. The first stitch (the in-seam) connects the upper, the insole, and the welt together. A second, separate stitch (the out-seam) then attaches the outsole to the welt.

The Cork-Filled Cavity

This construction method creates a cavity between the insole and the outsole. This space is filled with a layer of granulated cork, which provides cushioning, insulation, and shock absorption. Over time, this cork bed molds to the wearer's foot, creating a custom-like fit.

Understanding the Trade-offs

While the Goodyear welt is an industry benchmark, it is essential to understand its specific characteristics. Its strengths are also the source of its few drawbacks.

Unmatched Durability and Reparability

This is the primary benefit. Because the outsole is stitched only to the welt, a cobbler can easily remove it and sew on a new one without affecting the shoe's upper structure. This allows for multiple resoles, extending the life of a single pair of shoes for decades.

Superior Water Resistance

The welt creates a more robust barrier between the sole and the upper, significantly reducing the amount of water that can penetrate the shoe compared to methods where the stitch runs directly from the outsole into the shoe's interior.

Higher Initial Cost

The process is more complex and labor-intensive than modern alternatives. It requires more materials and skilled operation, resulting in a higher initial purchase price.

A Necessary Break-In Period

Goodyear-welted shoes are famously stiff when new. The robust construction and thick leather require a break-in period for the cork to mold and the leather to soften, but this process results in a uniquely comfortable and supportive fit.

Making the Right Choice for Your Goal

Understanding the history and mechanics of the Goodyear welt empowers you to invest in footwear that aligns with your specific needs.

- If your primary focus is longevity and a long-term investment: A Goodyear-welted shoe is the undisputed choice, offering unparalleled durability and the ability to be rebuilt over many years.

- If your primary focus is immediate, out-of-the-box comfort: A Blake-stitched or high-quality cemented shoe might feel more flexible at first, though you will sacrifice water resistance and long-term reparability.

- If your primary focus is minimizing initial cost: Cemented (glued) construction provides the most accessible price point, but it should be viewed as a short-term purchase that generally cannot be resoled.

By choosing a Goodyear-welted shoe, you are investing in more than a century of manufacturing excellence.

Summary Table:

| Feature | Impact |

|---|---|

| Mechanization | Transformed a slow, skilled craft into a scalable industry. |

| Durability | Created a benchmark for long-lasting, resoleable footwear. |

| Accessibility | Democratized access to high-quality shoes for a broader market. |

| Legacy | Remains the gold standard for quality work and dress shoes today. |

Invest in a Legacy of Quality

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear-welted and other durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you can offer your customers the longevity and value this historic construction method provides.

Ready to build a superior footwear line? Contact our team today to discuss your manufacturing needs and leverage our expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What is the vamp of a dress shoe and how should it be cared for? Preserve Your Investment with Proper Care

- Why are Oxford shoes considered the most versatile business footwear? Master Professional Style

- How is Vegano leather unique in terms of finish and use? A Masterpiece for Custom Patinas & Artisanal Footwear

- Why is it important to rest men's dress shoes between wears? The Secret to Doubling Their Lifespan

- What is a recommended color for captoe dress boots? Choose Dark Oxblood for Unmatched Versatility

- Is heel slip normal in new cowboy boots? Yes, and it's a sign of a great fit.

- What are the best boot colors to pair with a suit? Master Formal & Modern Style

- What should be considered when choosing exotic skin dress shoes? A Guide to Making a Confident Statement