Historically, lace-to-toe boots were significant in work footwear for providing superior structural support and a highly customizable fit. This design, with its lacing system extending down towards the toe box, was a functional innovation commonly found in classic work and hiking boots for workers who required maximum stability on their feet all day.

The historical value of the lace-to-toe boot is not merely aesthetic; it's a purpose-built design engineered to deliver a more secure, locked-in fit than standard boots, a critical advantage for workers navigating demanding and uneven terrain.

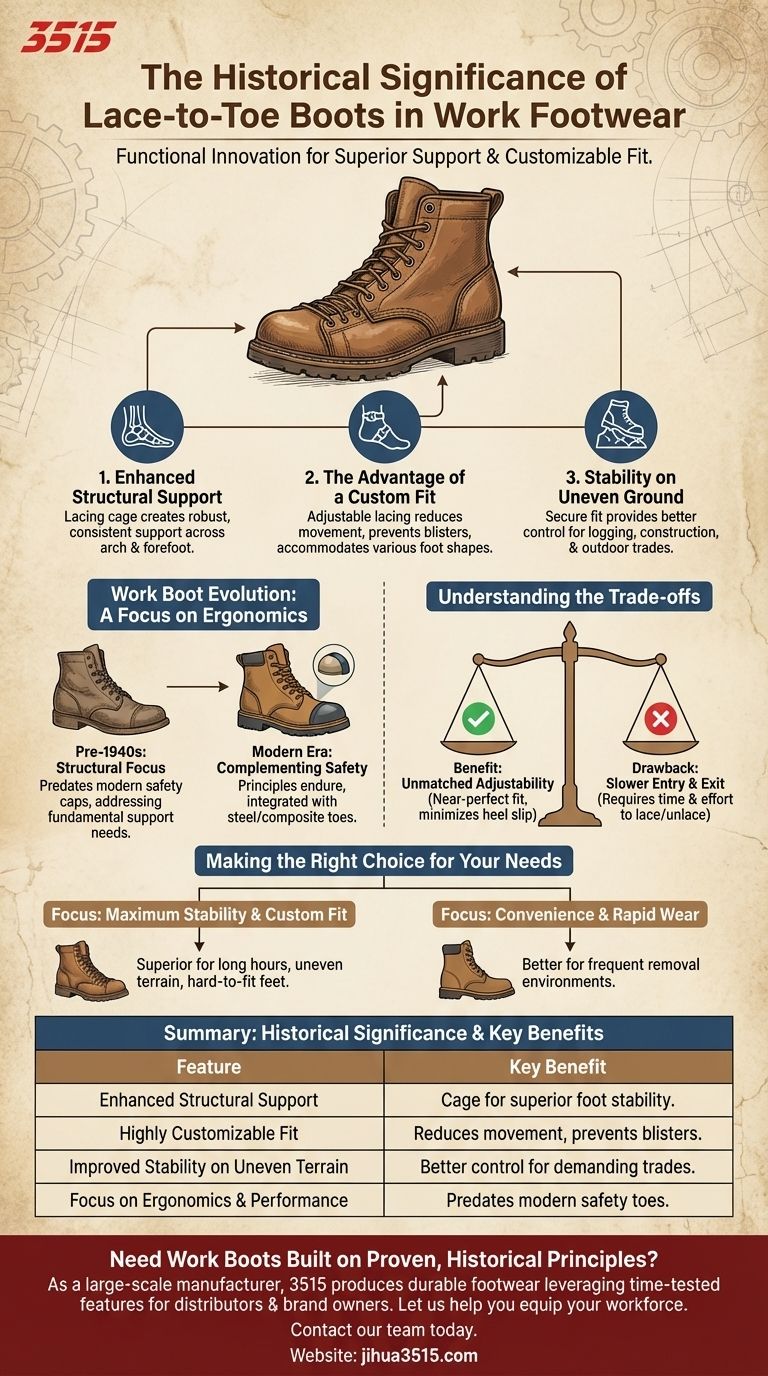

The Functional Origins of the Lace-to-Toe Design

The adoption of the lace-to-toe style in historical workwear was driven by practical needs. It was a direct solution to the challenges of comfort, stability, and endurance required for manual labor.

A Legacy of Enhanced Support

Unlike standard boots that primarily secure the ankle, the lace-to-toe design creates a structural cage around the entire foot.

By extending the lacing closer to the toes, the boot offers more robust and consistent support across the arch and forefoot.

The Advantage of a Custom Fit

This design's key historical significance lies in its adjustability. Workers could tighten or loosen the fit across a much larger area of the foot.

This was crucial for accommodating different foot widths and volumes, reducing internal foot movement, and preventing blisters during long hours of labor.

Stability on Uneven Ground

The enhanced support and custom fit directly translated to better stability, especially on the uneven surfaces common in logging, construction, and other outdoor trades.

A securely fitted boot gives the worker better control and reduces the risk of ankle rolls and foot fatigue.

Where It Fits in Work Boot Evolution

While modern safety features are a more recent development, the lace-to-toe pattern represents an earlier focus on the ergonomic and structural aspects of work footwear.

An Era Before Modern Safety Caps

The concept of protective footwear is relatively modern, with early wooden sabots giving way to steel toe caps around the 1940s.

The lace-to-toe design predates these specific safety innovations, focusing instead on the fundamental need for a stable and supportive boot structure.

Complementing, Not Competing

The lace-to-toe design is a feature centered on fit and performance. It has endured because its principles are still valid and can be integrated into boots that also feature modern safety components like steel or composite toes.

Understanding the Trade-offs

While historically significant for its benefits, the design has inherent characteristics that represent a trade-off between adjustability and convenience.

The Benefit: Unmatched Adjustability

The primary advantage has always been the ability to achieve a near-perfect fit. This minimizes heel slip and accommodates a wide variety of foot shapes, which is why it remains popular in high-performance hiking and work boots.

The Drawback: Slower Entry and Exit

The most obvious downside is the time and effort required to lace up and unlace the boots. For workers who need to put on and remove their footwear frequently, a standard lacing system is often more practical.

Making the Right Choice for Your Needs

The historical principles behind the lace-to-toe boot are just as relevant today. Choosing this style depends entirely on your specific work environment and priorities.

- If your primary focus is maximum stability and a custom fit: The lace-to-toe design remains a superior choice, especially for long hours on uneven terrain or for individuals with hard-to-fit feet.

- If your primary focus is convenience and rapid wear: A standard lacing pattern will likely serve you better in environments where you frequently need to remove your boots.

Ultimately, understanding the functional history of the lace-to-toe boot empowers you to choose footwear based on proven performance principles.

Summary Table:

| Historical Significance | Key Benefit |

|---|---|

| Enhanced Structural Support | Lacing to the toe creates a cage for superior foot stability. |

| Highly Customizable Fit | Adjustable fit reduces foot movement and prevents blisters. |

| Improved Stability on Uneven Terrain | Secure fit provides better control for logging, construction, etc. |

| Focus on Ergonomics & Performance | Predates modern safety toes, addressing fundamental support needs. |

Need Work Boots Built on Proven, Historical Principles?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, including designs that leverage time-tested features like superior support and customizable fits for maximum comfort and safety.

Let us help you equip your workforce with reliable footwear.

Contact our team today to discuss your specific needs and discover how we can support your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why are moc toe boots popular? The Perfect Blend of Rugged Durability and Timeless Style

- What should electricians look for in work boots? Prioritize EH-Rated Protection for Maximum Safety

- Why are waterproof safety boots recommended for certain work environments? Essential Protection for Wet & Hazardous Jobs

- How often should safety boots be replaced? A Guide to Lifespan & Safety Signs

- Why are men's work boots not appropriate safety footwear for women? Key Fit & Safety Risks Explained

- Why is electrical hazard protection necessary in fire boots? A Critical Defense Against Electrocution

- What are the advantages of soft toe work boots? Boost Comfort & Mobility for Long Shifts

- How do cowboy boots benefit construction workers? Enhance Safety and Support on the Job Site