The modern engineer boot is a direct descendant of military riding boots, refined and adapted to meet the unforgiving demands of the American Industrial Revolution. Its key influences are the tall, protective cavalry boots of the 17th through 19th centuries, particularly the US Army Cavalry boot, which were stripped of ornamentation and rebuilt for the specific hazards faced by railroad workers and firemen in the 1930s.

The engineer boot is not a singular invention but a powerful synthesis. It combines the protective structure of centuries-old equestrian and military footwear with the functional necessities of early 20th-century industrial labor, creating a design where every feature tells a story of purpose.

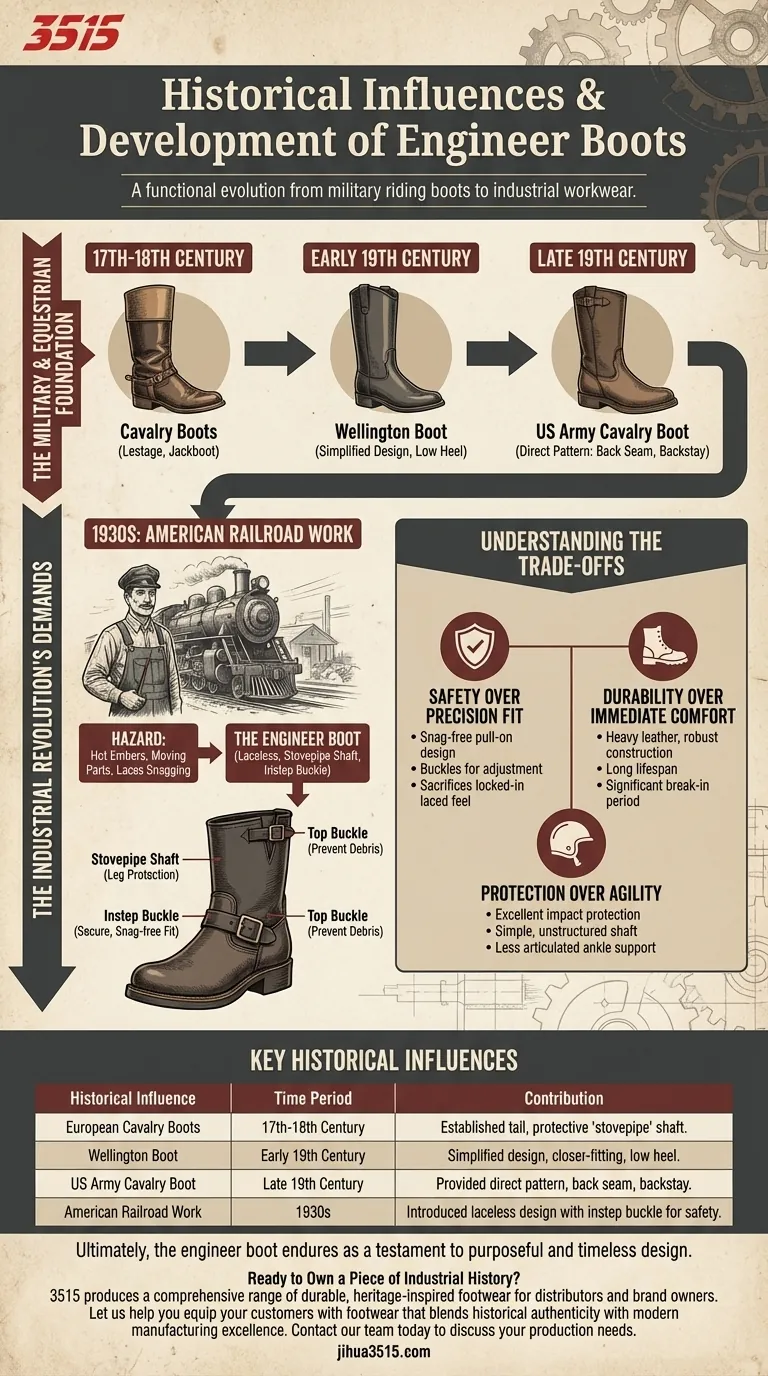

The Military and Equestrian Foundation

The core silhouette of the engineer boot was established long before the first railroads. Its DNA comes from boots designed for one primary purpose: protecting a rider's leg while on horseback.

Early Cavalry Roots

The boot's lineage begins with 17th-century European cavalry. Boots like the French Lestage seamless boot and the English jackboot were tall, rigid, and made of heavy leather to shield the rider's legs from injury in battle.

These early designs established the fundamental concept of a tall, durable "stovepipe" shaft as a piece of essential protective equipment.

The Evolution to a Simpler Form

Over the 18th century, these military boots evolved into more refined riding boots. The Hessian boot, with its signature tassel, gave way to the English Wellington boot.

The Wellington was a significant step closer to the engineer boot. It simplified the design, featuring a closer-fitting mid-calf shaft and a low, one-inch heel, making it more practical for both riding and walking.

The Direct American Predecessor

The most direct ancestor is the late 19th-century US Army Cavalry boot. This boot featured construction details—like a distinct back seam, a protective backstay, and a specific vamp pattern—that are nearly identical to those found on modern engineer boots.

Its design was purely functional, stripped of the decorative elements of earlier European styles, setting the stage for a true work boot.

The Industrial Revolution's Demands

While the pattern came from the cavalry, the boot's final form was forged in the fire and steel of Depression-era America. The engineer boot was born to solve a new set of industrial problems.

A New Kind of Hazard

Workers on steam locomotives, the "engineers" and "firemen," faced constant threats. Hot embers from the firebox could fall and burn their feet and legs, and the moving parts of the engine could easily snag the laces of conventional work boots, leading to catastrophic injury.

These workers needed a boot that was tall, protective, and completely free of laces.

Form Follows Function

The engineer boot's design directly addresses these hazards. The tall stovepipe shaft, inherited from riding boots, shields the lower leg from heat and debris.

The iconic instep buckle provides a secure, adjustable fit without the need for dangerous laces. A second buckle at the top of the shaft allows the wearer to cinch the boot, preventing embers and dirt from falling inside.

The Birth of an Icon

Between 1937 and 1939, bootmakers like Wesco and Chippewa began producing this purpose-built footwear. By marketing them specifically to railroad workers, they solidified the name "engineer boot" and created a new category of specialized workwear.

Understanding the Trade-offs

The engineer boot's highly specialized, laceless design is a masterclass in purpose-driven trade-offs. Its strengths in one area create inherent limitations in others.

Safety Over Precision Fit

The primary trade-off is sacrificing the customized fit of a laced boot for the snag-free safety of a pull-on design. While the buckles offer some adjustment, they cannot replicate the secure, locked-in feel of a tightly laced boot.

Durability Over Immediate Comfort

The use of heavy, full-grain leather and robust Goodyear welt or stitchdown construction makes the boot incredibly durable. However, this same tough construction means a significant break-in period is often required to achieve comfort.

Protection Over Agility

The simple, unstructured shaft provides excellent protection against direct impacts and debris. This design, however, offers less articulated ankle support compared to modern, tightly laced combat or hiking boots, a direct legacy of its simpler riding boot heritage.

How to Appreciate This Legacy

Understanding the engineer boot's history is to understand a masterclass in functional design. Its evolution reveals how an object's form is shaped by the problems it needs to solve.

- If your primary focus is historical lineage: Recognize that its core pattern is a direct, simplified evolution of the 19th-century US Cavalry boot.

- If your primary focus is functional problem-solving: See it as the brilliant solution to the specific life-or-death hazards faced by early American railroad workers.

- If your primary focus is iconic style: Appreciate that its rugged, authoritative aesthetic comes from an authentic blend of military heritage and blue-collar utility.

Ultimately, the engineer boot endures as a testament to design that is both purposeful and timeless.

Summary Table:

| Key Historical Influence | Time Period | Contribution to Engineer Boot Design |

|---|---|---|

| European Cavalry Boots | 17th-18th Century | Established the tall, protective 'stovepipe' shaft for leg protection. |

| Wellington Boot | Early 19th Century | Simplified design with a closer-fitting shaft and low heel for practicality. |

| US Army Cavalry Boot | Late 19th Century | Provided the direct pattern with back seam, backstay, and simplified style. |

| American Railroad Work | 1930s | Introduced the laceless design with instep buckle for safety against industrial hazards. |

Ready to Own a Piece of Industrial History?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, heritage-inspired footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, including modern interpretations of classic styles like the engineer boot, built with the same focus on durability and function that defined their origins.

Let us help you equip your customers with footwear that blends historical authenticity with modern manufacturing excellence. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk