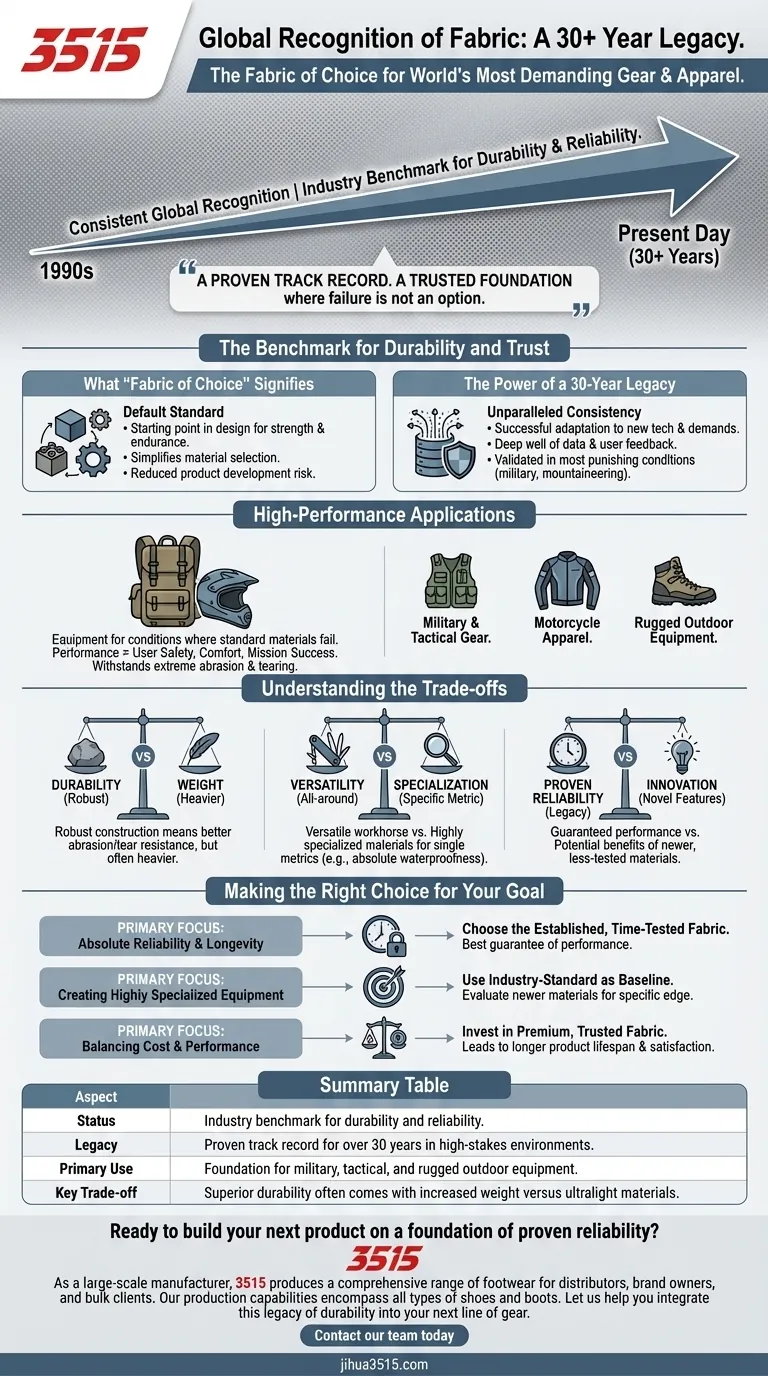

For over three decades, a specific class of high-performance fabric has earned consistent global recognition. It is overwhelmingly regarded as the fabric of choice for manufacturers creating the world's most demanding gear and apparel, establishing it as an industry benchmark for durability and reliability.

This long-standing recognition isn't just about brand reputation; it signifies a proven track record. It means that for generations of products, this fabric has been the trusted foundation for equipment where failure is not an option.

The Benchmark for Durability and Trust

When a material is called the "fabric of choice" for over 30 years, it means it has become the default standard against which others are measured. This status is earned, not marketed, through consistent performance in real-world, high-stakes environments.

What "Fabric of Choice" Signifies

This phrase indicates that when a manufacturer sets out to build top-tier equipment, this type of fabric is often the starting point in their design process. It's the material they trust to meet baseline requirements for strength and endurance.

This reliance simplifies the material selection process for brands known for quality. They are choosing a component with a well-documented history of performance, reducing risk in product development.

The Power of a 30-Year Legacy

A legacy spanning more than 30 years demonstrates unparalleled consistency. It means the fabric has successfully adapted to new technologies and evolving product demands without compromising its core attributes.

This history provides a deep well of data and user feedback. From military applications to mountaineering expeditions, its performance has been tested and validated countless times in the most punishing conditions.

Defining "High-Performance" Applications

High-performance gear is equipment designed for conditions where standard materials would quickly fail. This includes military packs, tactical vests, motorcycle apparel, and rugged outdoor equipment.

In these applications, fabric performance is directly linked to user safety, comfort, and mission success. The material must withstand extreme abrasion, tearing, and exposure to the elements without degrading.

Understanding the Trade-offs

No single material is perfect for every application. Being the established "fabric of choice" for durability often involves inherent trade-offs against other performance metrics. Understanding these helps in making an informed decision.

Durability vs. Weight

The robust construction required for exceptional abrasion and tear resistance often results in a heavier material. While ideal for gear like backpacks, it may be less suitable for ultralight apparel where every gram counts.

Versatility vs. Specialization

A fabric known for its all-around toughness is a versatile workhorse. However, highly specialized materials may outperform it in a single, specific metric, such as absolute waterproofness, static-free properties, or extreme-temperature insulation.

Proven Reliability vs. Cutting-Edge Innovation

While a 30-year legacy guarantees reliability, newer, more experimental textiles may offer novel features. The choice often comes down to prioritizing a proven history of performance versus the potential benefits of a new, less-tested material.

Making the Right Choice for Your Goal

Your specific objective determines which material attribute is most critical. Use the legacy of this fabric as a guide to inform your own selection criteria.

- If your primary focus is absolute reliability and longevity: Choose the established, time-tested fabric, as its track record is the best guarantee of performance.

- If your primary focus is creating highly specialized equipment: Use the industry-standard fabric as your performance baseline, then evaluate newer materials that may offer an edge in one specific area.

- If your primary focus is balancing cost and performance: Recognize that investing in a premium, trusted fabric often leads to a longer product lifespan and greater user satisfaction.

Ultimately, understanding why a material has been a global leader for decades empowers you to make smarter choices for your own needs.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Status | Industry benchmark for durability and reliability |

| Legacy | Proven track record for over 30 years in high-stakes environments |

| Primary Use | Foundation for military, tactical, and rugged outdoor equipment |

| Key Trade-off | Superior durability often comes with increased weight versus ultralight materials |

Ready to build your next product on a foundation of proven reliability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we understand the critical importance of using trusted, high-performance materials.

Let us help you integrate this legacy of durability into your next line of gear. Contact our team today to discuss your manufacturing needs and how we can deliver quality and reliability at scale.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- What are the essential steps for cleaning military boots? A Complete Guide to Preserve Your Gear

- What are the steps to clean suede military boots? A Complete Guide to Gentle, Effective Care

- Why are slip-resistant military boots important? The Foundation of Soldier Safety and Mission Success

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style