The design of the new Army Jungle Combat Boot (JCB) was refined through direct, iterative feedback from the soldiers who would ultimately depend on it. This input was gathered over a year of rigorous testing at the Jungle Operations Training Center in Hawaii, where soldiers evaluated multiple prototype versions in real-world conditions. Their experiences directly led to critical improvements in the boot's drainage, long-term comfort, and overall durability.

The development of the jungle boot was not just a design project; it was a problem-solving initiative. The core lesson is that successful equipment design hinges on a tight feedback loop with end-users to address the specific failures of previous technology in a given environment.

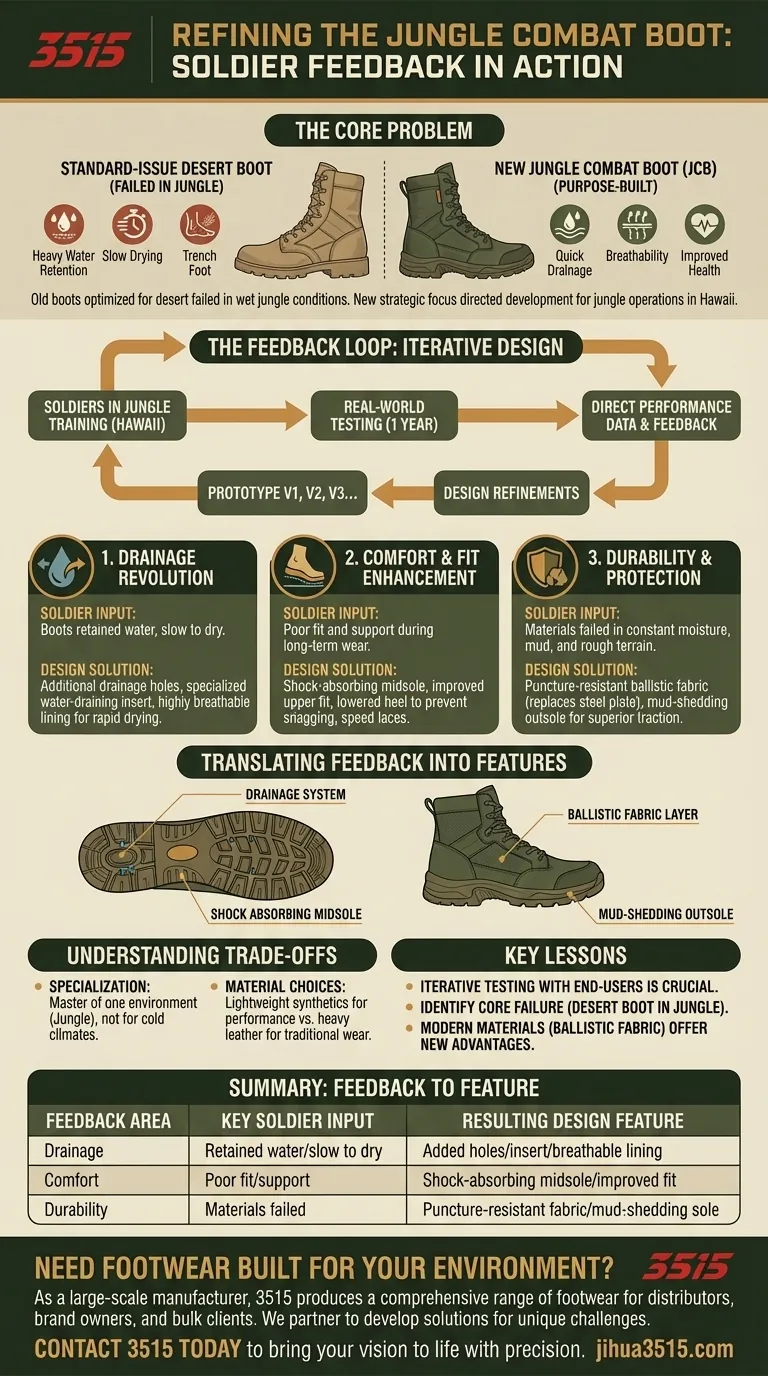

The Core Problem: Why a New Boot Was Necessary

Before examining the feedback, it's crucial to understand the problem it was meant to solve. The need for a new jungle boot arose from a clear operational gap.

Failure of the Standard-Issue Boot

The standard-issue combat boots used for years were optimized for the dry, sandy, and temperate environments of Iraq and Afghanistan. When used in hot, wet jungle conditions, they performed poorly. They retained water, were slow to dry, and contributed to foot ailments like trench foot.

A New Strategic Focus

The formal push for the JCB began when the Army Chief of Staff directed its development for two brigade combat teams operating in Hawaii. This established a clear mandate to create a boot purpose-built for the unique challenges of the jungle.

The Feedback Loop: How Soldiers Shaped the Design

The Army employed an iterative development process, using soldier feedback to make targeted improvements on successive versions of the boot.

The Proving Ground

Soldiers tested multiple variants of the JCB for approximately one year at the Jungle Operations Training Center. This provided a constant stream of data based on performance in the exact environment the boot was designed for.

Key Areas for Improvement

The feedback consistently centered on three critical performance areas:

- Drainage: How quickly the boot could shed water after being submerged.

- Comfort: How the boot fit and felt during long-term wear in wet conditions.

- Durability: How the materials and construction held up to the constant moisture, mud, and rough terrain.

A Tangible Health Impact

The value of this feedback was undeniable. One soldier specifically reported that switching from the standard desert boots to the JCB prototype completely eliminated the trench foot issues he had been experiencing. This type of direct medical and performance feedback was invaluable.

Translating Feedback into Technical Features

The soldier feedback was not just collected; it was systematically translated into specific engineering and design choices that differentiate the JCB from its predecessors.

Solving for Water

To address the critical need for drainage, designers incorporated additional drainage holes, a specialized water-draining insert, and a more breathable lining to accelerate drying time.

Mobility and Protection

Drawing inspiration from the Vietnam-era M1966 "Panama" jungle boot, the JCB features a mud-shedding outsole for superior traction. However, it replaces the old steel plate with a modern, puncture-resistant ballistic fabric layer, reducing weight without sacrificing safety.

Enhancing Comfort and Fit

For long-term wear, a shock-absorbing midsole was added. The boot's upper was redesigned for a better fit, the heel height was lowered to prevent snagging on roots, and speed laces were included for faster donning and doffing.

Understanding the Trade-offs

Creating a highly specialized piece of equipment like the JCB inevitably involves trade-offs. Objectivity requires acknowledging what this boot is not designed to do.

Specialization Over Versatility

The JCB is a master of one environment. Its focus on drainage and breathability means it offers minimal insulation, making it unsuitable for cold or even temperate climates. It is a purpose-built tool, not an all-around combat boot.

Material Choices and Durability

The lightweight, fast-drying synthetic materials are essential for jungle performance but have a different wear profile than the heavy, full-grain leather used in some other boots. The direct-attach construction, which fuses the sole to the upper, is excellent for preventing delamination in wet conditions but can be more difficult to repair.

Key Lessons from the Jungle Boot's Development

The creation of the JCB provides a clear blueprint for successful, user-focused equipment design.

- If your primary focus is product development: The JCB proves that iterative testing with end-users in their actual environment is the most effective way to validate a design.

- If your primary focus is problem-solving: The boot's success comes from correctly identifying the core failure—that a desert boot cannot function in a jungle—rather than just incrementally improving an existing design.

- If your primary focus is material science: This project shows the value of replacing traditional materials (steel) with modern alternatives (ballistic fabric) to gain specific performance advantages like reduced weight and improved flexibility.

Ultimately, the Jungle Combat Boot is a powerful case study in how targeted feedback transforms a piece of equipment into a genuine solution.

Summary Table:

| Feedback Area | Key Soldier Input | Resulting Design Feature |

|---|---|---|

| Drainage | Boots retained water, slow to dry | Added drainage holes, water-draining insert, breathable lining |

| Comfort | Poor fit and support during long-term wear | Shock-absorbing midsole, improved upper fit, lowered heel |

| Durability | Materials failed in constant moisture and mud | Puncture-resistant ballistic fabric, mud-shedding outsole |

Need Footwear Built for Your Specific Environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from specialized tactical gear to commercial workwear. Just as the Army refined its jungle boot through direct feedback, we partner with our clients to develop and manufacture footwear that solves their unique challenges.

Contact 3515 today to discuss how our expertise can bring your footwear vision to life with precision, durability, and purpose-driven design.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What are the essential steps for cleaning military boots? A Complete Guide to Preserve Your Gear

- What features should be looked for in slip-resistant military boots? Essential Guide for Maximum Grip & Stability

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon