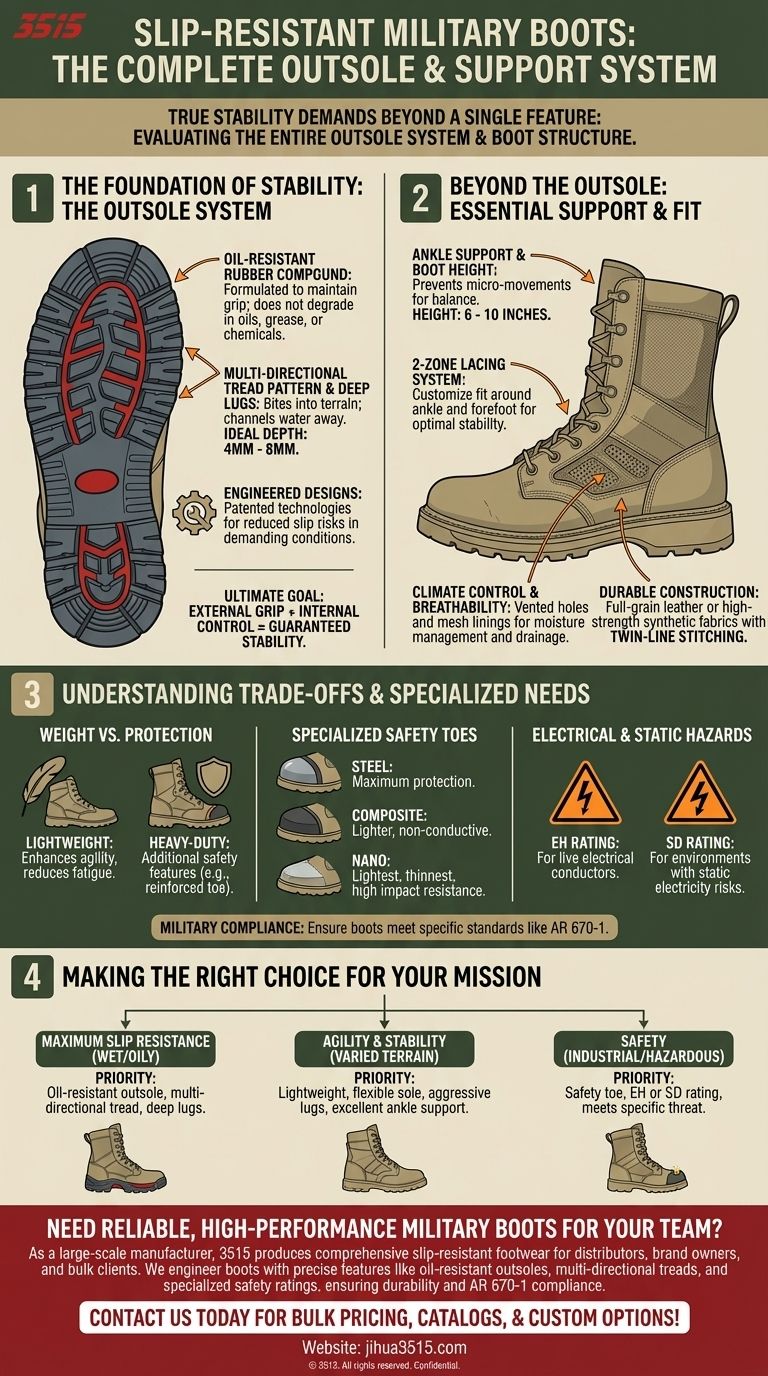

For true slip resistance in military boots, you must look beyond a single feature and evaluate the entire outsole system. The most critical characteristics are a multi-directional tread pattern with deep lugs, an oil-resistant rubber compound, and a construction that supports overall foot stability. These elements work together to provide reliable grip across unpredictable wet, oily, and uneven surfaces.

The ultimate goal is not just to prevent slips, but to guarantee stability. This is achieved through a combination of an expertly designed outsole for external grip and a supportive, well-fitted boot structure for internal foot control.

The Foundation of Stability: The Outsole

The outsole is the boot's point of contact with the ground and is the single most important component for slip resistance. Its effectiveness is determined by its material, pattern, and overall engineering.

Outsole Material and Compound

The specific rubber compound used in the outsole is your first line of defense. Look for materials explicitly rated as oil-resistant and slip-resistant.

These specialized compounds are formulated to maintain their grip and not degrade when exposed to oils, grease, or other common chemicals found on industrial or tactical surfaces.

Tread Pattern and Lug Depth

A simple flat sole will not suffice. An effective tread uses deep, aggressive channels called lugs to bite into the terrain and channel water away from the sole's surface.

Look for a lug depth between 4mm and 8mm. Furthermore, a multi-directional tread pattern is crucial, providing reliable grip whether you are moving forward, stopping suddenly, or changing direction on uneven ground.

Patented and Engineered Designs

Top-tier manufacturers often invest heavily in research and development, resulting in patented outsole designs. These are engineered and tested specifically to reduce slip risks in the most demanding conditions.

The presence of a patented or branded outsole technology often indicates a higher level of performance and reliability.

Beyond the Outsole: Essential Support and Fit

A world-class outsole is ineffective if your foot is not secure inside the boot. Overall boot construction is critical for translating the outsole's grip into confident movement.

Ankle Support and Boot Height

Proper ankle support prevents the micro-movements that can lead to a loss of balance and a subsequent slip.

Look for boots with a height between 6 and 10 inches, which provides excellent support without excessively restricting mobility. A 2-zone lacing system allows you to customize the fit around your ankle and forefoot for optimal stability.

Climate Control and Breathability

Dry feet are stable feet. Features like vented holes and breathable mesh linings are crucial for managing moisture from sweat or external water.

These systems increase airflow and allow for drainage, preventing your foot from sliding inside the boot and ensuring your footing remains secure.

Durable Construction

The boot must be able to withstand harsh use without losing its structural integrity. Look for durable materials like full-grain leather or high-strength synthetic fabrics.

Features like twin-line stitching add strength and ensure the boot continues to provide the necessary support over its entire lifespan.

Understanding the Trade-offs and Specialized Needs

Not all military-style boots are created equal. Depending on your specific environment, you may need to prioritize certain features over others.

Weight vs. Protection

Modern boots offer a range of protective features, but they often come with a trade-off in weight. Lightweight boots enhance agility and reduce fatigue, which can be critical for long patrols or rapid movement.

Heavier boots may incorporate additional safety features like reinforced toe caps, which might be necessary for certain job sites.

Specialized Safety Toes

If you work in an environment with impact or compression hazards, a safety toe is non-negotiable.

- Steel toes offer maximum protection.

- Composite toes are lighter and do not conduct heat, cold, or electricity.

- Nano toes provide the lightest and thinnest option with high impact resistance.

Electrical and Static Hazards

For work around live electrical conductors, you must have boots with an Electrical Hazard (EH) rating.

Conversely, in environments where a buildup of static electricity is a danger (e.g., around sensitive electronics or flammable materials), you need boots with a Static Discharge (SD) rating.

Military Compliance

If you are in the service, ensure the boots meet or exceed specific military requirements, such as AR 670-1. This standard governs everything from materials to height, ensuring the boot is authorized for duty.

Making the Right Choice for Your Mission

Your specific operational environment dictates the ideal combination of features.

- If your primary focus is maximum slip resistance in wet or oily environments: Prioritize a boot with a documented oil-resistant outsole, a multi-directional tread, and deep lugs.

- If your primary focus is agility and stability on varied, natural terrain: Look for a lightweight boot with excellent ankle support, a flexible sole, and aggressive lugs.

- If your primary focus is safety in an industrial or hazardous setting: You must select a boot that matches the specific threats, whether that means a steel toe, an EH rating, or SD protection.

Ultimately, choosing the right boot is an investment in a complete system designed to keep you stable, safe, and effective when it matters most.

Summary Table:

| Key Feature | Why It Matters | Ideal Specs |

|---|---|---|

| Outsole Material | Provides grip on wet/oily surfaces | Oil-resistant rubber compound |

| Tread Pattern & Lug Depth | Bites into terrain, channels water away | Multi-directional, 4mm-8mm depth |

| Ankle Support & Height | Prevents micro-movements for balance | 6-10 inch height, 2-zone lacing |

| Safety Toe Options | Protects against impact/compression hazards | Steel, composite, or nano toes |

| Specialized Ratings | Addresses electrical/static hazards | EH (Electrical Hazard) or SD (Static Discharge) rating |

Need reliable, high-performance military boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military boots and tactical footwear, engineered with the precise features outlined above—from oil-resistant outsoles and multi-directional treads to specialized safety ratings.

We ensure durability, compliance with standards like AR 670-1, and custom solutions tailored to your operational needs. Let us equip your personnel with boots that guarantee stability and safety in the most demanding conditions.

Contact us today for bulk pricing, catalogs, and custom manufacturing options!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do combat boots function to provide support and protection? Discover the Integrated System

- What makes wildfire boots unique? A Deep Dive into Essential Fireline Safety Gear

- What are the benefits of maintaining military boots? Ensure Mission Readiness and Maximize Lifespan

- What are the pros and cons of classic jungle boots? Durability vs. Comfort for Harsh Environments

- What are the key features of the Boots Original Camo Red Desert? Designed for All-Day Comfort & Style

- What materials are commonly used to enhance the durability of military boots? Discover the Material System for Ultimate Toughness

- What is the purpose of the camouflage pattern? To Deceive the Eye and Conceal Effectively

- What role did the Desert Boot play in 1960s fashion? The Definitive Footwear of British Mod Culture