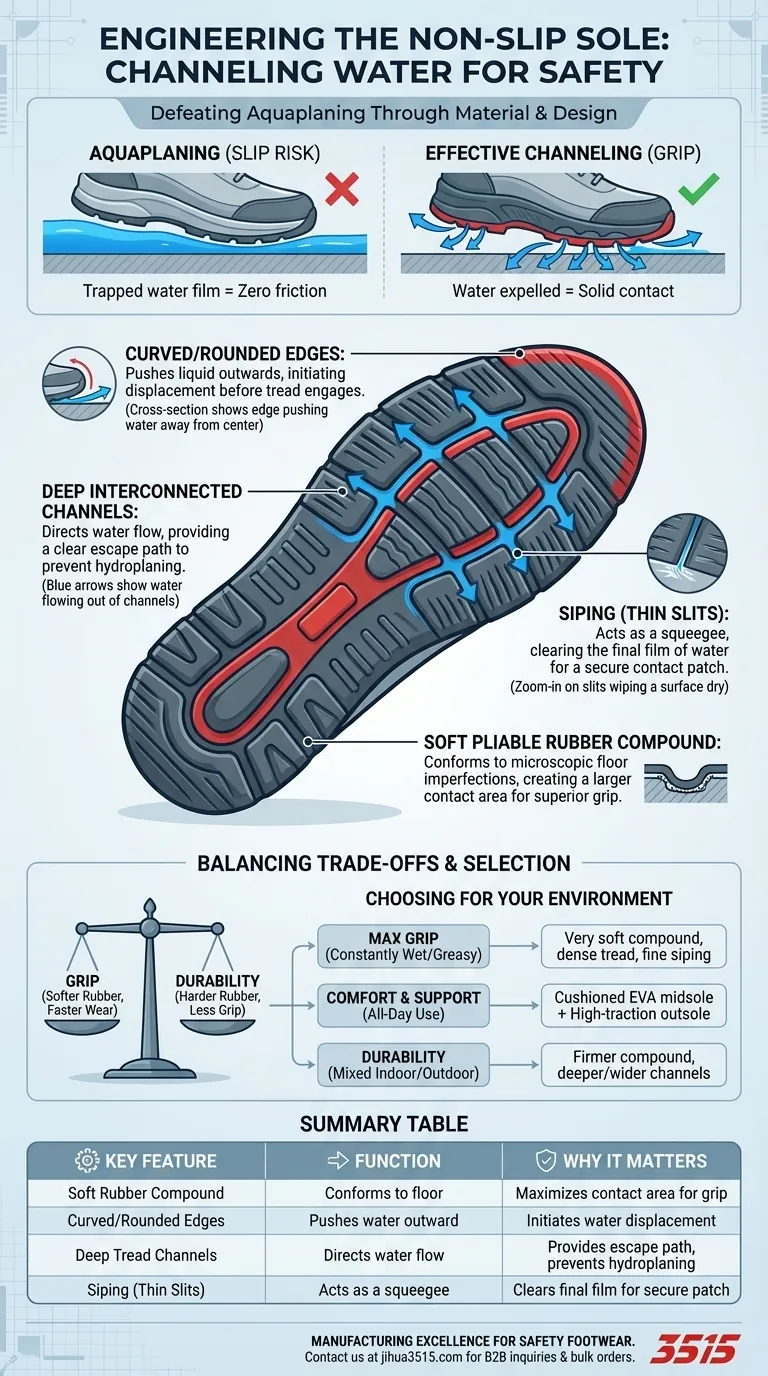

To effectively channel water, the sole of a non-slip shoe must combine a specific shape and material composition. Key features include slightly curved or rounded outer edges to push liquid outwards, a tread pattern with distinct channels to direct flow, and construction from a soft, pliable rubber that can maintain maximum contact with the ground surface.

The core principle of a non-slip sole is not just to resist water, but to actively manage it. Its design is engineered to expel liquid from underneath the shoe, preventing a hydroplaning effect and ensuring the rubber makes direct, solid contact with the floor.

The Core Principle: Defeating the Aquaplaning Effect

A slip doesn't happen because a floor is wet. It happens because a thin, often invisible layer of liquid prevents your shoe from ever truly touching the floor. An effective non-slip shoe is designed to overcome this specific problem.

How Water Causes Slips

When you step on a wet surface, your body weight can trap a layer of water between your shoe and the floor. This liquid film dramatically reduces friction, similar to how a car aquaplanes on a wet road.

The Role of an Engineered Outsole

The outsole of a non-slip shoe functions like a high-performance car tire. Its primary job is to channel water out from under the foot as quickly as possible, allowing the sole's material to make a firm, dry connection with the ground.

Key Design Features for Water Management

The effectiveness of a non-slip shoe is determined by a synergy of material science and geometric design. Each feature plays a critical role in moving water and maintaining grip.

Material Composition: Soft vs. Hard Rubber

The outsole must be made of a relatively soft rubber compound. While harder materials may last longer, they cannot conform to the microscopic imperfections of a flooring surface.

Soft rubber is pliable, allowing it to create a much larger surface area of contact, which is the foundation of superior grip. Materials like leather or rigid plastics are unsuitable as they slide easily over liquid.

The Importance of Curved Edges

The references consistently highlight rounded or curved edges on the sole. This is not an aesthetic choice; it is a functional one.

As you step, these curved sides help push water outwards and away from the center of the shoe, beginning the channeling process before the full tread pattern even engages.

Tread Pattern and Siping

The specific pattern of grooves, or tread, is the most critical element for channeling water. Deep, interconnected channels give the displaced water a clear path to escape from underneath the sole.

Many top-tier non-slip shoes also incorporate siping—tiny, hair-thin slits in the rubber. These sipes act as squeegees, further clearing away the last film of liquid to create a secure contact patch.

Understanding the Trade-offs

Choosing the perfect non-slip shoe involves balancing competing factors. There is no single sole that is best for every situation.

Durability vs. Grip

The softest rubber compounds provide the best possible grip, but they also wear down the fastest. A shoe designed for the extreme demands of a commercial kitchen may not be durable enough for abrasive outdoor surfaces.

The Misconception of "Rigid" Soles

Some sources mention rigidity, creating confusion. It is crucial to distinguish between structural integrity and material softness.

The sole's overall design and deep channels need to be structurally sound and not collapse under pressure. However, the rubber material that actually touches the floor must remain soft and flexible to grip effectively.

Making the Right Choice for Your Goal

Selecting the right non-slip shoe requires matching its design features to your specific environment and needs.

- If your primary focus is maximum grip in constantly wet or greasy environments: Prioritize a sole made from a very soft rubber compound with a dense, complex tread pattern and fine siping.

- If your primary focus is all-day comfort and support: Ensure the shoe has a cushioned EVA (Ethylene-vinyl acetate) midsole in addition to a high-traction rubber outsole.

- If your primary focus is durability for mixed indoor and outdoor use: Look for a sole with a slightly firmer rubber compound and deeper, wider channels that are less likely to clog with debris.

By understanding how a sole is designed to manage water, you can confidently select the footwear that provides true stability for your specific environment.

Summary Table:

| Key Feature | Function | Why It Matters |

|---|---|---|

| Soft Rubber Compound | Conforms to floor surfaces | Maximizes contact area for superior grip |

| Curved/Rounded Edges | Pushes water outward | Initiates water displacement before the tread engages |

| Deep Tread Channels | Directs water flow | Provides a clear escape path for liquid to prevent hydroplaning |

| Siping (Thin Slits) | Acts as a squeegee | Clears the final film of water for a secure contact patch |

Need reliable non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in engineering soles with the perfect balance of soft rubber compounds, effective tread patterns, and durable construction ensures maximum safety and comfort.

Let's discuss your specific requirements and get a quote for your next order.

Contact our team today to get started!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort