To select the right police footwear, officers must prioritize an outsole built from a high-traction material combined with a lug pattern designed for their specific operational environment. The most common and effective materials are specialized rubber compounds for superior grip and polyurethane for exceptional durability and resistance to wear.

The outsole is the most critical safety feature of a boot. Its design directly determines your stability, traction, and confidence across the unpredictable surfaces you face on duty, making it a non-negotiable factor for operational readiness.

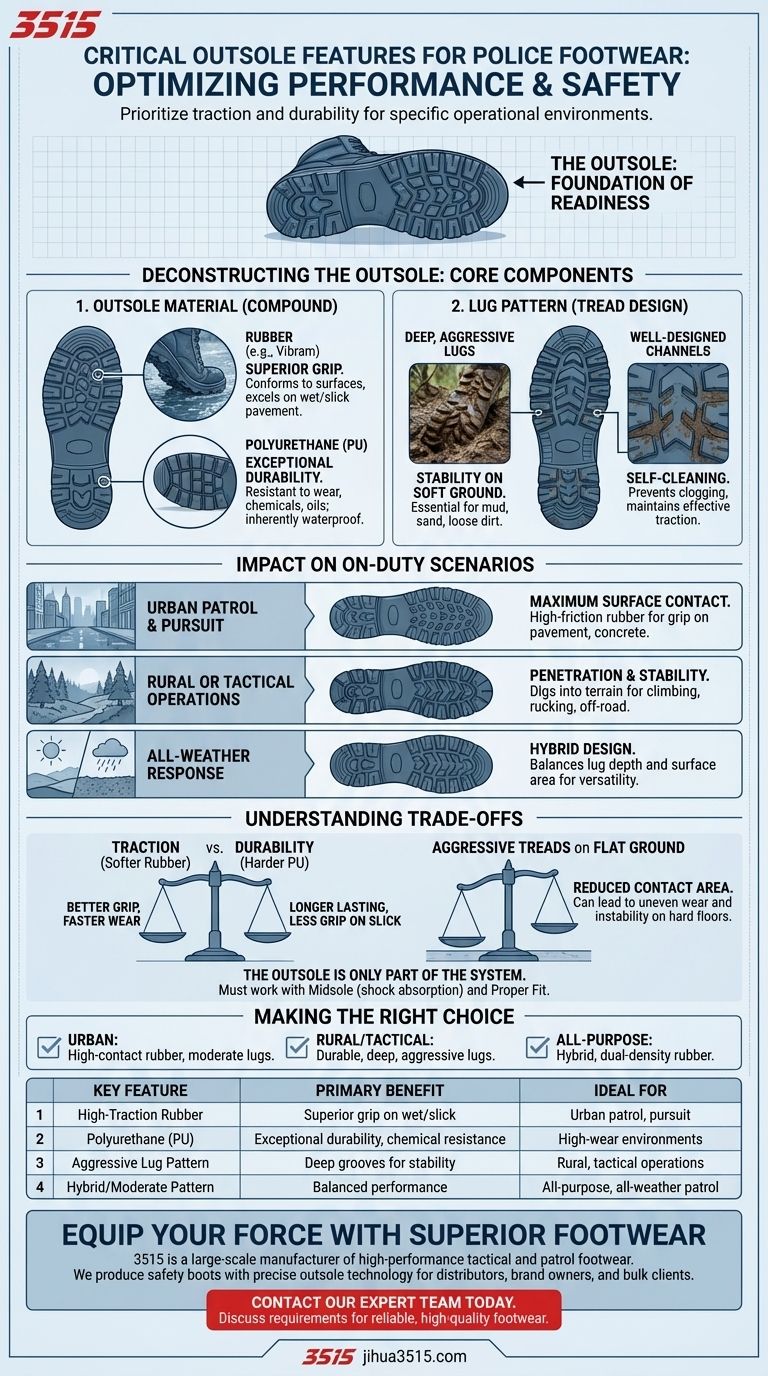

Deconstructing the Outsole: The Two Core Components

An effective outsole is a system of two parts working together: the material it's made from and the tread pattern molded into it. Understanding how each contributes to performance is key.

Outsole Material: The Foundation of Performance

The compound used for the outsole dictates its fundamental characteristics of grip and longevity.

Rubber compounds, like those made by Vibram, are the gold standard for traction. Their inherent softness and flexibility allow them to conform to microscopic imperfections in a surface, providing superior grip, especially on wet or slick pavement.

Polyurethane (PU) is a thermoplastic known for its incredible durability and resistance to abrasion. While generally harder than rubber, it excels in high-wear environments and offers excellent resistance to chemicals and oils, along with inherent waterproofing.

Lug Pattern: Translating Power into Grip

The tread design, or lug pattern, is what allows the material to function effectively on different types of terrain.

Lugs are the deep grooves and channels on the bottom of the boot. Deeper, more aggressive lugs are essential for digging into soft surfaces like mud, sand, or loose dirt, providing stability and preventing slips.

Well-designed patterns also feature channels that are wide enough to clear mud and debris. This self-cleaning action ensures the lugs remain effective and don't become clogged, which would turn your sole into a dangerous, flat surface.

How Outsole Design Impacts On-Duty Scenarios

The ideal outsole changes based on the primary environment where an officer works. What excels in a rural setting may be a liability on city streets.

For Urban Patrol and Pursuit

On pavement, concrete, and linoleum, the primary need is maximum surface contact for grip. An outsole with shallower, more numerous lugs made of a high-friction rubber compound is ideal for maintaining traction during a foot pursuit on a wet street.

For Rural or Tactical Operations

In environments with mud, sand, and uneven ground, the focus shifts to penetration and stability. Deep, widely spaced, multi-directional lugs are critical for digging into the terrain, providing the grip needed for climbing, rucking, or moving through wooded areas.

For All-Weather Response

For officers who face a mix of conditions, a hybrid design is often best. These outsoles balance lug depth with enough surface area to perform well on both hard surfaces and loose ground, ensuring you are prepared for any call.

Understanding the Trade-offs

No single outsole is perfect for every situation. Choosing the right one means understanding the inherent compromises in design.

Traction vs. Durability

Softer rubber compounds provide the best grip but tend to wear down faster, especially on abrasive surfaces like concrete. Harder polyurethane outsoles last significantly longer but may offer less traction on slick, flat surfaces.

Aggressive Treads on Flat Ground

While deep lugs are essential for mud, they can reduce the amount of surface contact on flat pavement. This can lead to faster, uneven wear and may feel less stable during prolonged standing on a hard floor.

The Outsole is Only Part of the System

An elite outsole cannot compensate for a poor midsole or improper fit. The midsole provides critical shock absorption and support from components like EVA foam or steel shanks, while a proper fit ensures the entire system works with your foot, not against it.

Making the Right Choice for Your Role

Select your boot's outsole based on the terrain you encounter most frequently.

- If your primary focus is urban patrol: Prioritize a high-contact rubber outsole with a multi-directional, moderate lug pattern for superior grip on slick pavement and indoor surfaces.

- If your primary focus is rural or tactical duty: Choose a durable outsole with deep, aggressive, and widely-spaced lugs to maximize traction on mud, dirt, and uneven terrain.

- If your primary focus is all-purpose patrol: Look for a hybrid outsole that balances lug depth with sufficient surface area, often made from a dual-density rubber for both grip and longevity.

Ultimately, your choice of outsole is a direct investment in your safety and ability to perform your duties effectively from the ground up.

Summary Table:

| Key Feature | Primary Benefit | Ideal For |

|---|---|---|

| High-Traction Rubber | Superior grip on wet/slick surfaces | Urban patrol, pursuit |

| Polyurethane (PU) | Exceptional durability, chemical resistance | High-wear environments |

| Aggressive Lug Pattern | Deep grooves for stability on soft ground | Rural, tactical operations |

| Hybrid/Moderate Pattern | Balanced performance for varied terrain | All-purpose, all-weather patrol |

Ready to Equip Your Force with Superior Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance tactical and patrol footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots designed with the precise outsole technology discussed here—ensuring your team has the traction, durability, and safety they need for any operational environment.

Contact our expert team today to discuss your specific requirements and discover how we can support your mission with reliable, high-quality footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is the weight of police boots an important consideration? Balance Fatigue & Protection for Peak Performance

- How do well-designed law enforcement boots improve job performance? Enhance Officer Safety and Agility

- What are the main types of police footwear? A Guide to Durable & Specialized Footwear

- What are the key features to look for in firefighting boots? Ensure Maximum Safety and Performance

- What factors should be considered when buying police boots? A Guide to Safety, Comfort & Durability

- How do police tactical boots with running-shoe technology differ from standard models? Boost Comfort & Agility for Demanding Operations

- How do socks affect the fit of police footwear? Optimize Your Duty Gear for Maximum Comfort

- What materials are recommended for durable police boots? The Ultimate Guide to Long-Lasting Footwear