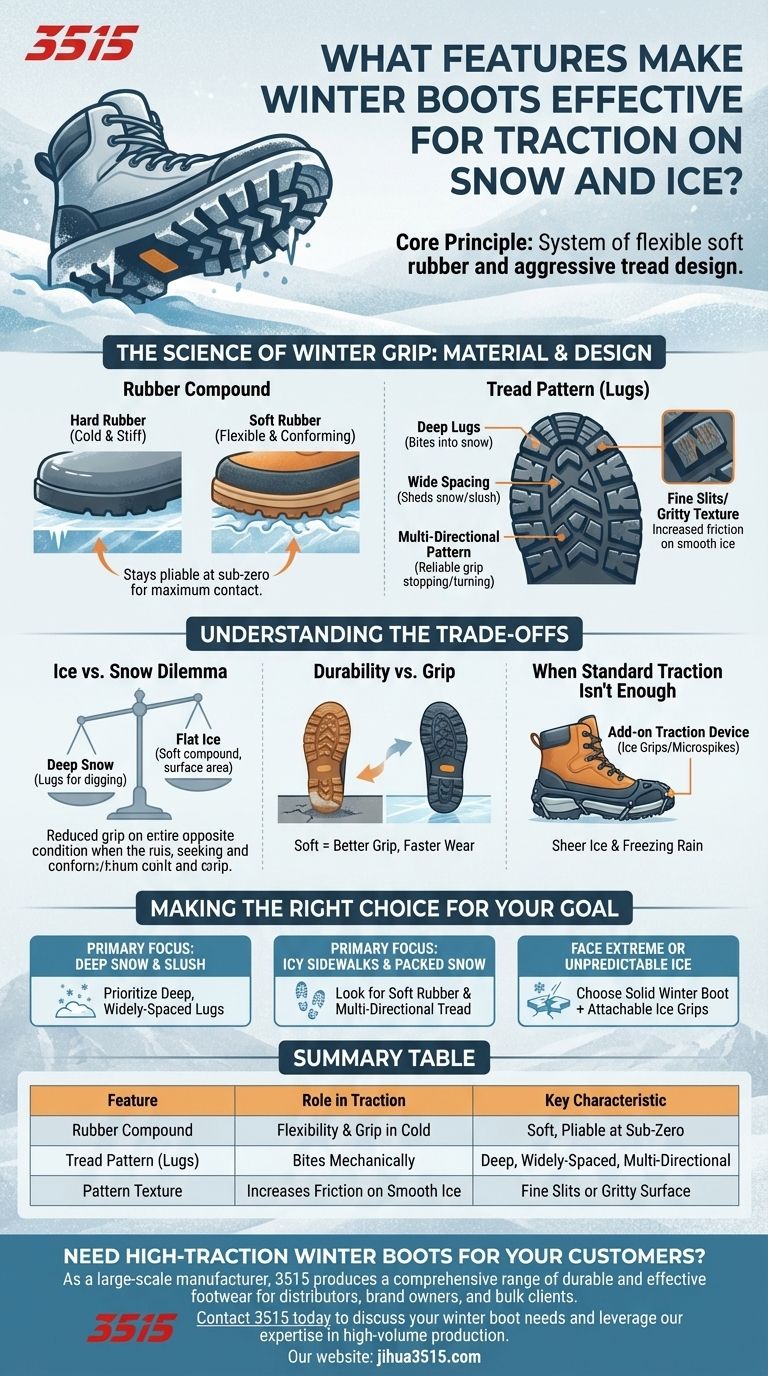

To be truly effective on snow and ice, a winter boot's traction comes from a combination of two critical features: the material composition of the outsole and the physical design of its tread. The best winter boots use a soft rubber compound that remains pliable in freezing temperatures, combined with a deep, aggressive tread pattern, known as lugs, to mechanically grip uneven and slippery surfaces.

The core principle of winter traction is not just about having a deep tread, but about a system where the boot's material remains flexible enough to conform to the ground while its design actively bites into snow and ice.

The Science of Winter Grip: Material and Design

Understanding why some boots grip while others slip requires looking closely at the outsole—the part that meets the ground. It's a careful balance of chemistry and engineering.

The Critical Role of the Rubber Compound

A boot's primary defense against slipping is its outsole material. Many all-season boots use harder rubber compounds that become stiff and slick in the cold, much like a summer car tire on an icy road.

Effective winter boots use a specialized, softer rubber compound. This material is engineered to stay flexible even at sub-zero temperatures, allowing it to better conform to microscopic imperfections in the ice and snow, maximizing surface contact and grip.

Deconstructing the Tread Pattern (The Lugs)

The physical shape of the tread is what provides mechanical grip. These patterns are made of lugs—the deep, protruding sections of the sole.

The depth and spacing of the lugs are crucial. Deep lugs bite into soft or unpacked snow, while wider spacing helps shed snow and slush so the tread doesn't get clogged and lose its effectiveness.

The Importance of Pattern and Texture

A good winter tread pattern is multi-directional. This ensures reliable grip not just when walking forward, but also when stopping, turning, or navigating slopes. Some outsoles also feature very fine slits or a gritty texture to increase friction on smooth, slick ice.

Understanding the Trade-offs

No single boot is perfect for every winter condition. Choosing the right features means understanding the inherent compromises involved in their design.

The Ice vs. Snow Dilemma

Features optimized for deep snow, like extremely deep and widely spaced lugs, can sometimes reduce the amount of surface area in contact with flat ice, slightly decreasing grip there.

Conversely, boots designed for ice often rely more heavily on a very soft rubber compound and may have a less aggressive tread, making them less effective in deep powder.

Durability vs. Grip

The soft rubber compounds that provide excellent cold-weather grip are often less durable than harder rubbers. If you wear your winter boots frequently on dry pavement, the high-grip soles will likely wear down faster.

When Standard Traction Isn't Enough

On sheer, slick ice, even the best boot sole has its limits. For the most hazardous conditions, such as freezing rain or established ice flows, the only reliable solution is an add-on traction device, such as ice grips or microspikes.

Making the Right Choice for Your Goal

Select your boots based on the conditions you face most often. Your primary winter environment dictates which traction features you should prioritize.

- If your primary focus is deep snow and slush: Prioritize boots with deep, widely-spaced lugs that can dig in and clear themselves effectively.

- If your primary focus is icy sidewalks and packed snow: Look for a boot with a visibly soft rubber outsole and a complex, multi-directional tread pattern for maximum surface contact.

- If you face extreme or unpredictable ice: Choose a solid winter boot while accepting you may need separate, attachable ice grips for the most dangerous days.

By understanding the interplay between material and design, you can confidently select a boot that provides the right foundation for safe winter travel.

Summary Table:

| Feature | Role in Traction | Key Characteristic |

|---|---|---|

| Rubber Compound | Provides flexibility and grip in cold | Soft, stays pliable at sub-zero temperatures |

| Tread Pattern (Lugs) | Bites into snow and ice mechanically | Deep, widely-spaced, and multi-directional |

| Pattern Texture | Increases friction on smooth ice | Fine slits or gritty surface |

Need high-traction winter boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and effective footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of winter boots, engineered with the precise rubber compounds and tread designs discussed here to ensure safety and performance.

Contact 3515 today to discuss your winter boot needs and leverage our expertise in high-volume production.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What key functions do industrial IoT monitoring devices perform in green smart footwear factories? Optimize Efficiency

- What are the long-term cost benefits of investing in quality boots? Save Money by Avoiding the Disposable Cycle

- Why is the restriction of Azo dyes critical in footwear production? Ensuring EU Market Access and Safety

- What are the advantages of 3/4 length arch supports for Hallux Valgus? Optimize Space and Comfort

- How do high-resolution digital barometers improve vertical navigation accuracy in complex indoor environments?

- How do micro-protrusions on functional textured insoles enhance foot balance? Boost Stability with Sensory Feedback

- How do retro-reflective fabrics compare to active light sources? Passive Reliability vs. Active Power for Road Safety

- How do wireless surface EMG systems and Ag/AgCl electrodes assess muscle fatigue? Scientific Fatigue Monitoring Guide