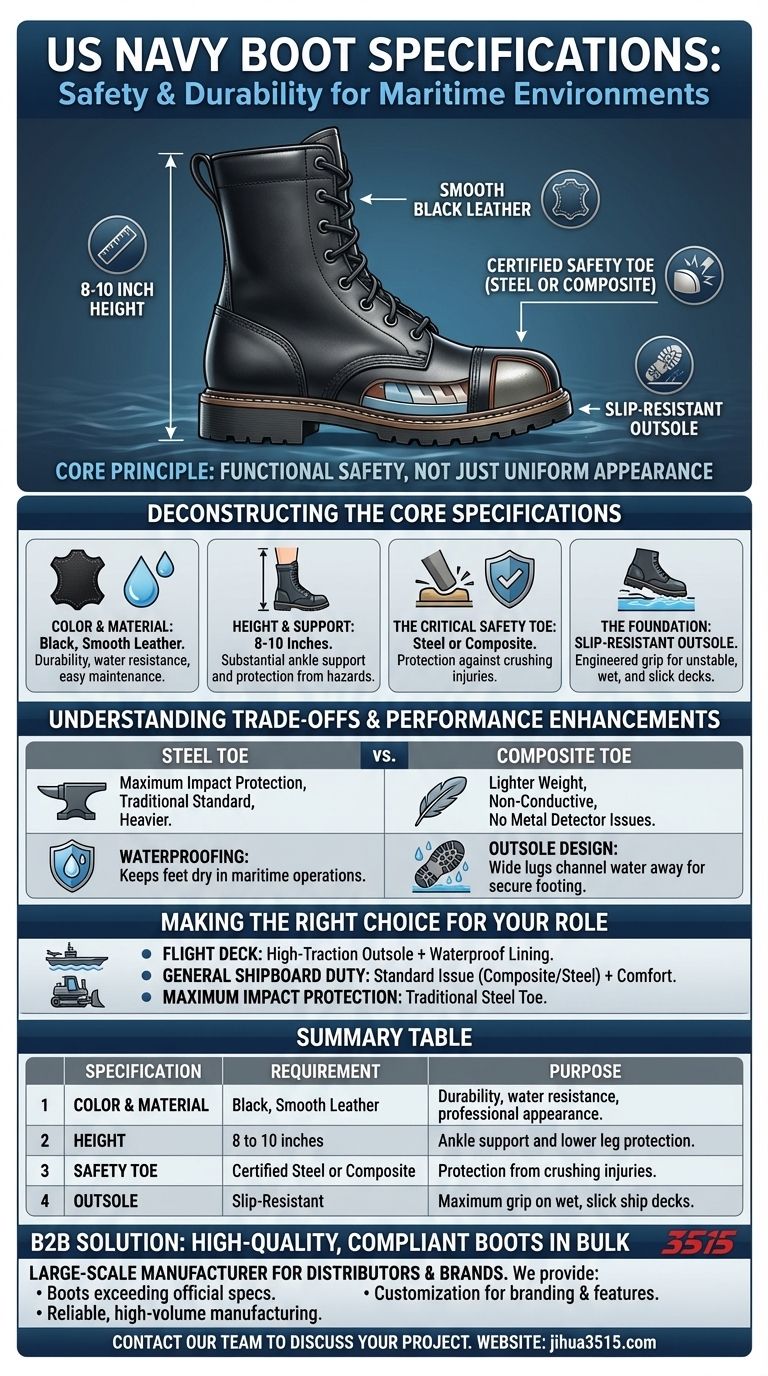

The specifications for official U.S. Navy boots are driven by the absolute need for safety and durability in a maritime environment. Authorized boots are required to be black, stand 8 to 10 inches high, and be constructed from smooth leather. Critically, they must feature a certified safety toe (either steel or composite) and a slip-resistant outsole to protect personnel on potentially wet and hazardous ship surfaces.

The core principle behind Navy boot specifications is not uniform appearance, but functional safety. While the basic requirements are fixed, understanding the "why" behind each feature—from the height to the outsole material—is key to appreciating their role as essential protective equipment.

Deconstructing the Core Specifications

To understand Navy-compliant footwear, you must look at each component as a solution to a specific environmental challenge found on a vessel.

Color and Material

The requirement for black, smooth leather is both practical and traditional. This construction provides excellent durability and water resistance, and it can be easily maintained to a professional standard of appearance.

Height and Support

The specified height of 8 to 10 inches offers a critical balance. It provides substantial ankle support and protects the lower leg from common workplace hazards without being as restrictive as a taller boot.

The Critical Role of the Safety Toe

All authorized boots must have a safety toe to protect against crushing injuries from heavy or rolling equipment. The regulations permit either steel or composite materials for this protective cap.

The Foundation: Slip-Resistant Outsoles

Perhaps the most critical feature for a Navy boot is a slip-resistant outsole. Decks can be unstable and are frequently exposed to water, oil, and other fluids. The outsole is engineered with specific rubber blends and tread patterns to maximize grip on these slick steel surfaces.

Beyond the Basics: Performance-Enhancing Features

While the core requirements are non-negotiable, certain features are highly sought after to enhance performance and comfort during long periods of duty.

Waterproofing for Maritime Operations

For personnel working on decks or in environments with constant exposure to water, a waterproof lining is an invaluable feature. This keeps feet dry, preventing discomfort and potential health issues.

Outsole Design and Traction

Advanced outsole designs feature wide lug patterns that help channel water away and maintain a secure footing. Unlike boots designed for rough terrain, the primary focus is on grip on flat, slippery surfaces, not digging into soft earth.

Understanding the Trade-offs and Regulations

Not all compliant boots are created equal. The choice between different materials and features involves understanding key trade-offs.

Steel Toe vs. Composite Toe

This is a common decision point. Steel toes offer maximum impact protection and are the traditional standard. However, composite toes are lighter, do not conduct heat or cold, and will not set off metal detectors, offering a more modern balance of safety and convenience.

The Line Between Regulation and Preference

While the foundational specs are mandatory, sailors often have a choice of authorized brands and models. This allows for personal preference in areas like cushioning, boot weight, and the inclusion of features like waterproofing, so long as the boot is officially certified for Navy use.

What Navy Boots Are Not

It is crucial to distinguish Navy boots from other specialized footwear. Unlike Lineman boots with their raised heels for climbing or European military boots designed for rugged terrain, Navy boots are purpose-built for the unique hazards of a ship.

Making the Right Choice for Your Role

Choosing a boot that meets regulations while suiting your specific duties is essential for both safety and performance.

- If your primary focus is flight deck operations: Prioritize a boot with a certified, high-traction outsole designed for wet and fuel-slicked surfaces and a reliable waterproof lining.

- If your primary focus is general shipboard duty: A standard-issue composite or steel-toe boot with good comfort and durability will serve you well, with waterproofing as a valuable optional feature.

- If your primary focus is maximum impact protection: A traditional steel toe offers the highest level of defense against crushing hazards.

Ultimately, a compliant Navy boot is a critical piece of safety equipment designed to protect you in one of the world's most demanding workplaces.

Summary Table:

| Specification | Requirement | Purpose |

|---|---|---|

| Color & Material | Black, Smooth Leather | Durability, water resistance, and professional appearance. |

| Height | 8 to 10 inches | Ankle support and lower leg protection. |

| Safety Toe | Certified Steel or Composite | Protection from crushing injuries. |

| Outsole | Slip-Resistant | Maximum grip on wet, slick ship decks. |

Need High-Quality, Navy-Compliant Boots in Bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-focused footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of compliant boots and shoes, built to meet the rigorous demands of maritime and industrial environments.

We provide:

- Boots that meet or exceed official specifications for safety, materials, and performance.

- Customization options for branding and specific feature requirements.

- Reliable, high-volume manufacturing to ensure your supply chain is secure.

Let's discuss your project. Contact our team today to request a quote or learn how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are some casual outfit pairings for desert boots? Master Versatile Style for Any Occasion

- How is Cordura used in military and outdoor gear? For Unmatched Durability & Reliability

- What is the significance of slip-resistant outsoles in combat boots? Ensure Mission-Critical Traction & Stability

- What features should be looked for in slip-resistant military boots? Essential Guide for Maximum Grip & Stability

- In what non-military scenarios are combat boots suitable? Discover Durability for Work, Outdoor, and Fashion

- How do military camouflage boots increase safety? Protection and Stealth for Extreme Environments

- What are the main benefits of wearing military boots for everyday use? Discover Unmatched Durability & Support

- What factors should be considered when choosing military boots for hiking? Durability vs. Weight for Your Terrain