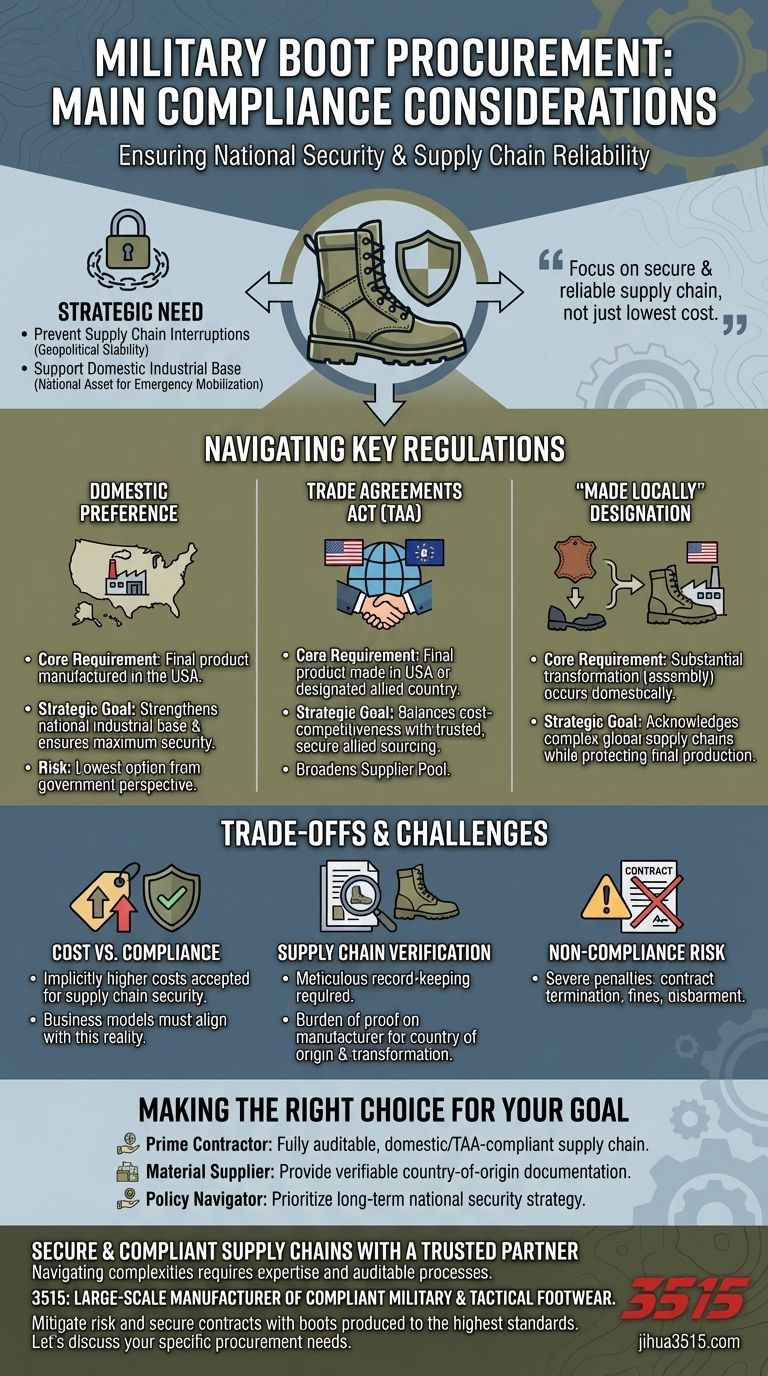

At its core, military boot procurement is governed by three primary compliance considerations: a strong preference for domestically produced goods, adherence to the Trade Agreements Act (TAA), and a specific "made locally" designation that allows for foreign materials in domestically assembled products. These regulations are designed not just for quality control, but as a matter of national security to prevent supply chain interruptions for critical equipment.

The central challenge in military procurement is not simply finding the best boot, but ensuring it is produced within a secure and reliable supply chain. Compliance regulations prioritize national industrial strength and strategic alliances over sourcing from the lowest-cost global producer.

The Strategic Need: Why Sourcing Location Matters

The rules governing where military boots can be made are rooted in a deep strategic need for self-reliance and supply chain security. The location of manufacturing is considered a critical component of military readiness.

Avoiding Supply Chain Interruptions

A core goal is to prevent a situation where the supply of essential gear for soldiers could be threatened by geopolitical instability or conflict. Relying on potentially adversarial nations for manufacturing creates an unacceptable vulnerability.

Supporting the Domestic Industrial Base

By mandating domestic or allied production, the government ensures that manufacturing capabilities and skilled labor are maintained within the United States. This industrial base is a strategic asset, crucial for mobilizing production during a national emergency.

Navigating Key Procurement Regulations

While the goal is straightforward, the specific rules require careful navigation. Understanding the distinction between domestic preference and TAA compliance is essential for any potential supplier.

The Preference for Domestic Goods

There is an explicit preference for goods produced on U.S. soil. This is the most straightforward path to compliance and is seen as the lowest-risk option from a government procurement standpoint. It directly supports the goal of a robust national industrial base.

The Role of the Trade Agreements Act (TAA)

The TAA provides a crucial exception. It allows the government to purchase goods made in designated allied or partner countries. This broadens the potential supplier pool while still keeping it within a network of trusted nations, balancing cost-competitiveness with supply chain security.

The Nuance of "Made Locally"

This designation addresses the complexity of modern supply chains. A boot can be designated as "made locally" or TAA-compliant even if its raw materials (like leather or rubber) come from a non-designated country. The key requirement is that the final, "substantial transformation" of those materials into a boot occurs within the U.S. or a TAA-designated country.

Understanding the Trade-offs and Challenges

Complying with these regulations involves significant trade-offs and presents challenges that suppliers must manage effectively.

Cost vs. Compliance

Manufacturing in the U.S. or TAA-designated countries is often more expensive than manufacturing elsewhere. The government implicitly accepts this higher cost as a necessary trade-off for securing its supply chain. Suppliers must build their business models around this reality.

Supply Chain Verification

The burden of proof is on the manufacturer. You must be able to document the country of origin for all components and prove where the substantial transformation took place. This requires meticulous record-keeping and supply chain transparency.

The Risk of Non-Compliance

Failing to meet these procurement standards leads to severe consequences. These can include contract termination, financial penalties, and being barred from future government contracts. The reputational damage can be equally severe.

Making the Right Choice for Your Goal

To succeed in this space, you must align your manufacturing and sourcing strategy directly with these compliance realities.

- If your primary focus is becoming a prime government contractor: Your top priority must be establishing a fully-auditable supply chain that is either entirely domestic or strictly TAA-compliant.

- If your primary focus is supplying materials to a boot manufacturer: You must provide clear, verifiable country-of-origin documentation for every component you sell.

- If your primary focus is navigating procurement policy: Recognize that decisions are driven by long-term national security strategy, where supply chain resilience consistently outweighs finding the lowest unit price.

Ultimately, understanding these compliance frameworks is the first and most critical step to participating in the defense supply chain.

Summary Table:

| Key Compliance Area | Core Requirement | Strategic Goal |

|---|---|---|

| Domestic Preference | Final product manufactured in the USA. | Strengthens national industrial base and ensures supply chain security. |

| Trade Agreements Act (TAA) | Final product made in the USA or a designated allied country. | Balances cost-competitiveness with trusted, secure sourcing from allies. |

| "Made Locally" Designation | Substantial transformation (assembly) occurs domestically, even if materials are foreign. | Acknowledges complex global supply chains while protecting final production. |

Ready to Ensure Your Military Boots Meet Strict Government Compliance?

Navigating the complexities of domestic preference and TAA compliance requires a manufacturing partner with proven expertise and a transparent, auditable supply chain. As a large-scale manufacturer, 3515 produces a comprehensive range of compliant footwear for distributors, brand owners, and bulk clients seeking government contracts.

We help you mitigate risk and secure contracts by ensuring your boots are produced to the highest standards within the required compliance frameworks. Our production capabilities encompass all types of military boots and tactical footwear.

Let's discuss your specific procurement needs. Contact our team today to build a secure and compliant supply chain.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why are professional training shoes critical for safety? Expert Guide to Plyometric Stability and Performance

- How do specialized training shoes and sneakers support high-intensity training? Maximize Performance & Stability

- How can high-quality tactical or athletic footwear mitigate social participation restrictions? Enhance Your Mobility

- How do professional athletic shoes contribute to safety on flexible balance boards? Enhance Stability & Prevent Slips

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability