Choosing the right slip-resistant shoe is a critical safety decision. The most important factors to consider are the outsole's material and tread pattern, the shoe's overall comfort and fit for long-term wear, and its durability against the specific hazards of your environment, such as water, oil, or chemicals. These elements work together to provide reliable traction and prevent workplace accidents.

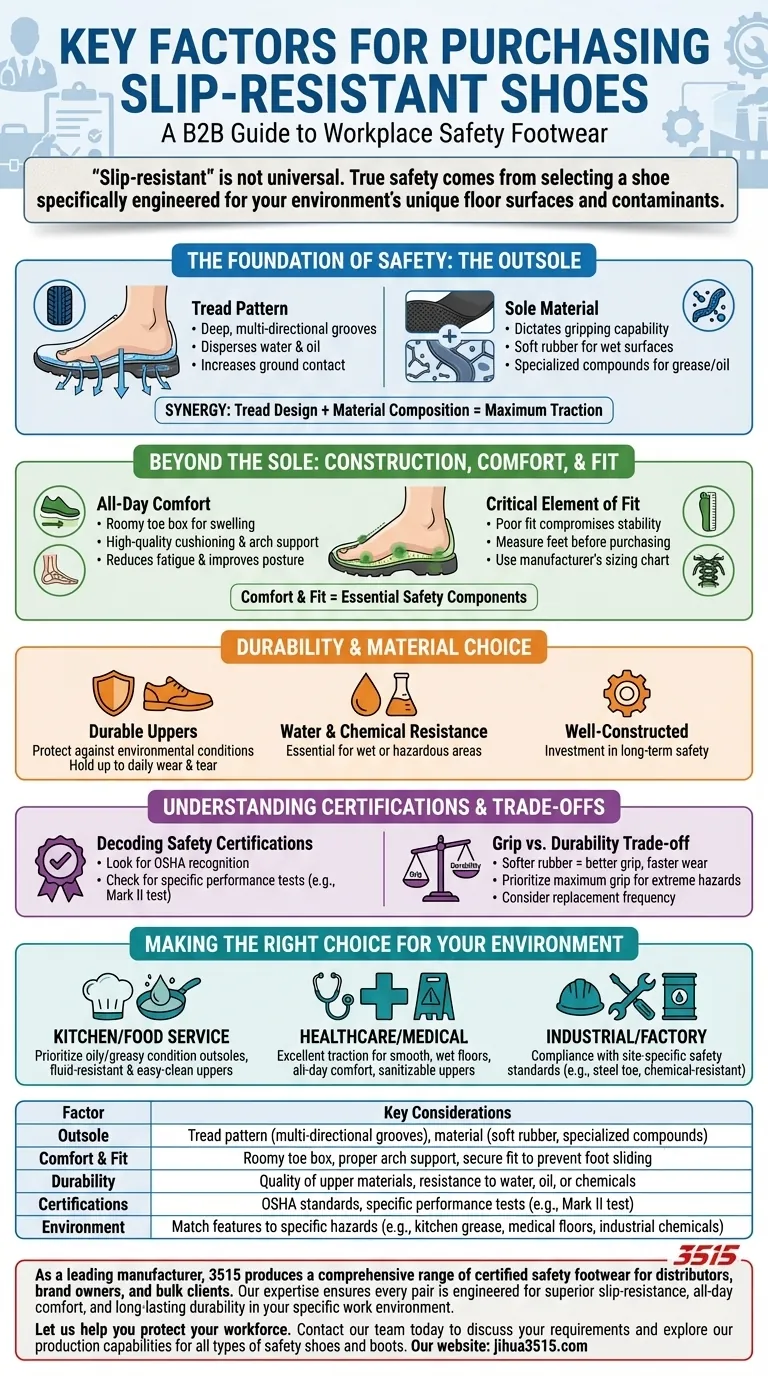

The term "slip-resistant" is not a universal guarantee of safety. True effectiveness comes from selecting a shoe specifically engineered for your environment's unique floor surfaces and contaminants. The synergy between the sole's tread design and its material composition is the single most important factor in preventing falls.

The Foundation of Safety: The Outsole

The outsole is the part of the shoe that contacts the floor, and its design is paramount for safety. Its effectiveness is determined by two key components: the tread pattern and the material.

The Role of Tread Pattern

A shoe's tread pattern acts much like the tires on a car. Its primary job is to channel liquids out from under the sole to maintain direct contact with the floor.

Look for patterns with deep, multi-directional grooves. These channels effectively disperse water, oil, and other fluids, significantly increasing the surface area of the sole that grips the ground.

The Importance of Sole Material

The material of the outsole dictates its gripping capability. Soft rubber is a common and effective choice for providing traction, especially on wet surfaces.

However, specialized compounds are often used to resist specific hazards. For example, shoes designed for kitchens will use a rubber compound formulated to maintain its grip on greasy and oily floors, a common cause of slips.

Beyond the Sole: Construction, Comfort, and Fit

An effective shoe is one you will actually wear correctly for an entire shift. Comfort and proper fit are not luxuries; they are essential components of safety and productivity.

Ensuring All-Day Comfort

Workers who are on their feet all day experience foot swelling. A shoe with a roomy toe box accommodates this change, preventing pain and discomfort.

Features like high-quality cushioning and proper arch support reduce fatigue, which in turn helps you maintain focus and proper posture, further reducing the risk of accidents.

The Critical Element of Fit

A poorly fitting shoe is a dangerous shoe. If your foot slides inside the shoe, your stability is compromised before the outsole even does its job.

Always measure your feet before purchasing and consult the manufacturer's specific sizing chart. A secure, comfortable fit ensures the shoe works with your foot, not against it.

Durability and Material Choice

A slip-resistant shoe is an investment in your safety. The materials of the upper shoe should be durable and, if necessary, water-resistant to protect your feet from environmental conditions.

Choosing a well-constructed shoe from a reputable source ensures it will hold up to daily wear and tear, providing consistent protection over time.

Understanding Certifications and Trade-offs

Not all slip-resistant shoes are created equal. Understanding what to look for on the label and the inherent compromises in design will help you make a more informed decision.

Decoding Safety Certifications

Look for shoes that meet established safety standards, such as those recognized by the Occupational Safety and Health Administration (OSHA).

Some manufacturers will also cite specific performance tests, like the Mark II test, which measure the shoe's coefficient of friction on various surfaces. These certifications provide objective proof of a shoe's protective capabilities.

The Balance Between Grip and Durability

There is often a trade-off between the softness of the sole and its longevity. A softer rubber compound provides excellent grip but may wear down more quickly.

Consider your environment and how often you are willing to replace your footwear. For extremely hazardous conditions, prioritizing maximum grip over a longer lifespan is the safest choice.

Making the Right Choice for Your Environment

To select the best shoe, match its features directly to your workplace hazards and daily demands.

- If your primary focus is a kitchen or food service environment: Prioritize shoes with outsoles specifically rated for oily and greasy conditions and ensure the uppers are fluid-resistant and easy to clean.

- If your primary focus is a healthcare or medical setting: Look for excellent traction on smooth, wet floors, all-day comfort for long shifts, and uppers that can be easily sanitized.

- If your primary focus is an industrial or factory environment: You must consider compliance with site-specific safety standards, which may require features like a steel toe or chemical-resistant materials in addition to a high-traction outsole.

Investing in the correct, certified footwear is the most reliable way to ensure your safety and stability at work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Outsole | Tread pattern (multi-directional grooves), material (soft rubber, specialized compounds) |

| Comfort & Fit | Roomy toe box, proper arch support, secure fit to prevent foot sliding |

| Durability | Quality of upper materials, resistance to water, oil, or chemicals |

| Certifications | OSHA standards, specific performance tests (e.g., Mark II test) |

| Environment | Match features to specific hazards (e.g., kitchen grease, medical floors, industrial chemicals) |

As a leading manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair is engineered for superior slip-resistance, all-day comfort, and long-lasting durability in your specific work environment.

Let us help you protect your workforce. Contact our team today to discuss your requirements and explore our production capabilities for all types of safety shoes and boots.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now