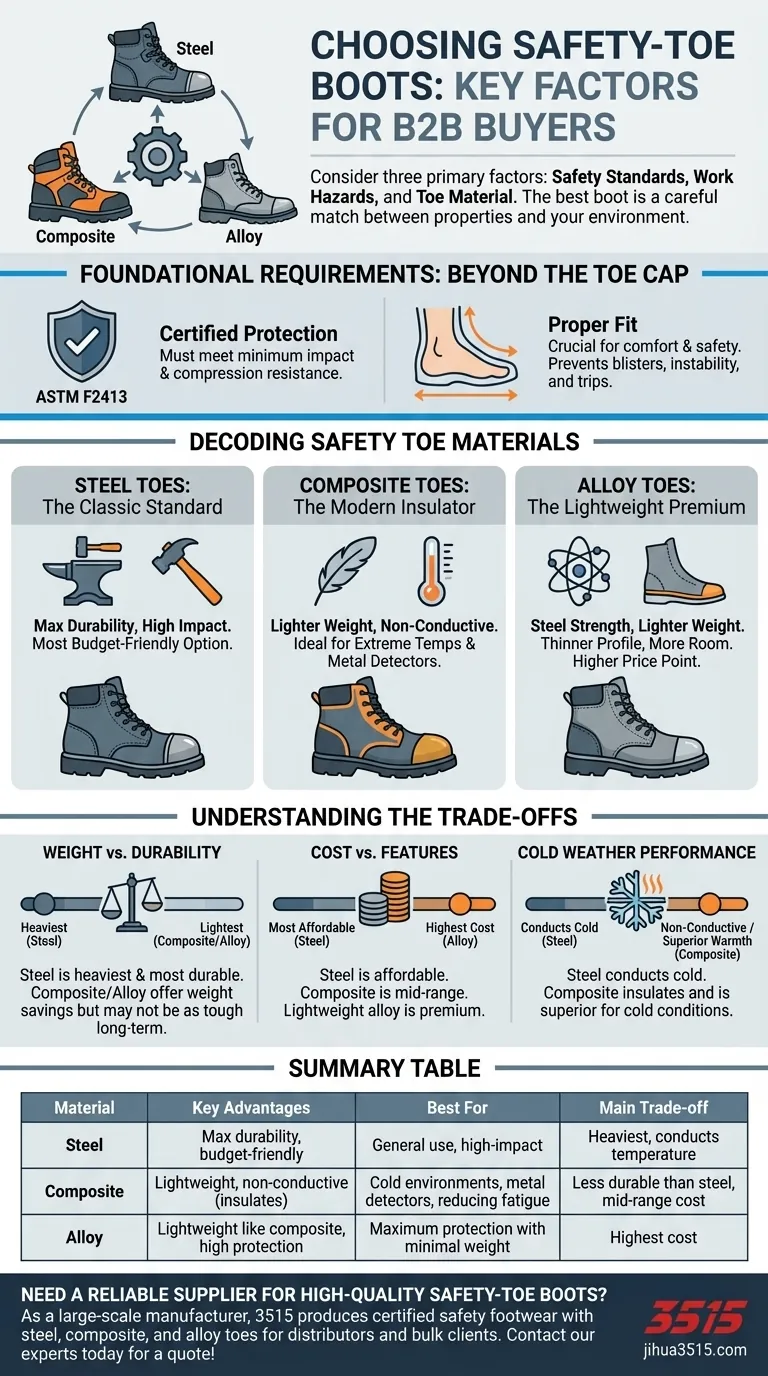

To make the right choice, you must consider three primary factors: the required safety standards for your job (like ASTM F2413), the specific hazards of your work environment, and the material of the safety toe itself. The main toe materials—steel, composite, and alloy—each offer a distinct set of trade-offs in weight, cost, and performance in different conditions.

The best safety-toe boot isn't determined by a single "best" material, but by a careful match between the toe cap's properties and the unique demands of your specific work environment and physical needs.

Foundational Requirements: Beyond the Toe Cap

Before comparing materials, two factors are non-negotiable for any safety boot: certified protection and a proper fit. Getting these wrong undermines any other feature.

Adherence to Safety Standards

Your first check should always be for compliance with safety standards, typically from the American Society for Testing and Materials (ASTM). Look for the ASTM F2413 rating, which confirms the boot meets minimum requirements for impact and compression resistance for the toe area.

The Critical Importance of Proper Fit

An ill-fitting boot is not just uncomfortable; it's a safety hazard. A boot that is too loose can cause blisters and instability, while one that is too tight can cause pain and circulation issues. Proper fit ensures comfort over long shifts and reduces the risk of trips, slips, and falls.

Decoding Safety Toe Materials

The material of the protective toe cap is the core variable that impacts your daily experience. Each has a distinct profile.

Steel Toes: The Classic Standard

Steel is the traditional material for safety toes, known for its exceptional strength and durability. It can withstand very high impacts and compression, often providing the highest level of protection available.

Because steel has been the industry standard for so long, these boots are widely available and are typically the most budget-friendly option.

Composite Toes: The Modern Insulator

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. Their primary advantage is that they are much lighter than steel, reducing foot fatigue over a long day.

Because they contain no metal, composite toes do not conduct cold, heat, or electricity. This makes them the ideal choice for workers in extreme temperatures or those who must pass through metal detectors frequently.

Alloy Toes: The Lightweight Premium

Alloy toes, often made from materials like aluminum or titanium, offer a middle ground. They provide the same level of impact and compression resistance as steel but at a significantly lighter weight.

These toe caps can also be made thinner than steel, resulting in a less bulky boot with more room in the toe box. This premium combination of protection and low weight typically comes at a higher price point.

Understanding the Trade-offs

Choosing a safety toe is a matter of balancing competing priorities. There is no single "best" choice, only the best choice for a specific application.

Weight vs. Durability

Steel is the heaviest but often considered the most durable against wear and tear. Composite and alloy toes offer significant weight savings, which can dramatically reduce fatigue, but may not withstand the same level of worksite abuse over the long term.

Cost vs. Features

There is a clear cost hierarchy. Steel toes are the most affordable, making them an excellent choice for general use or when budget is the main constraint. Composite toes are mid-range, while lightweight alloy toes are typically the most expensive option.

Cold Weather Performance

This is a critical differentiator. Steel readily conducts cold, making it a poor choice for refrigerated or outdoor winter environments without significant insulation. Composite toes are non-conductive, making them vastly superior for maintaining foot warmth in cold conditions.

Making the Right Choice for Your Goal

Select your boot by prioritizing the single most important factor for your work.

- If your primary focus is maximum durability on a strict budget: Choose steel-toe boots for their proven strength and low cost.

- If your primary focus is working in extreme cold, passing through metal detectors, or reducing foot fatigue: Choose composite-toe boots for their lightweight and non-conductive properties.

- If your primary focus is achieving the lightest possible weight without compromising on protection: Choose alloy-toe boots, provided the higher cost fits your budget.

Ultimately, understanding these core trade-offs empowers you to select the precise tool that will keep you safe and productive on the job.

Summary Table:

| Safety Toe Material | Key Advantages | Best For | Main Trade-off |

|---|---|---|---|

| Steel | Maximum durability, budget-friendly | General use, high-impact environments | Heaviest, conducts temperature |

| Composite | Lightweight, non-conductive (insulates) | Cold environments, metal detectors, reducing fatigue | Less durable than steel, mid-range cost |

| Alloy | Lightweight like composite, high protection | Maximum protection with minimal weight | Highest cost |

Need a reliable supplier for high-quality safety-toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We offer boots with steel, composite, and alloy toes to meet any worksite requirement, ensuring your team has the right protection, comfort, and durability.

Contact our experts today to discuss your needs and get a quote!

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- When should steel toe boots be replaced? Protect Your Feet from Costly Workplace Injuries

- What materials are used to make safety toes? Choose the Right Protection for Your Job

- What are the advantages of steel toe boots? Maximum Protection, Lower Cost & Streamlined Design

- What are the pros and cons of steel toe work boots? A Guide to Maximum Protection vs. Comfort

- How can you quickly break in steel toe boots? A Fast, Pain-Free Method for Comfort