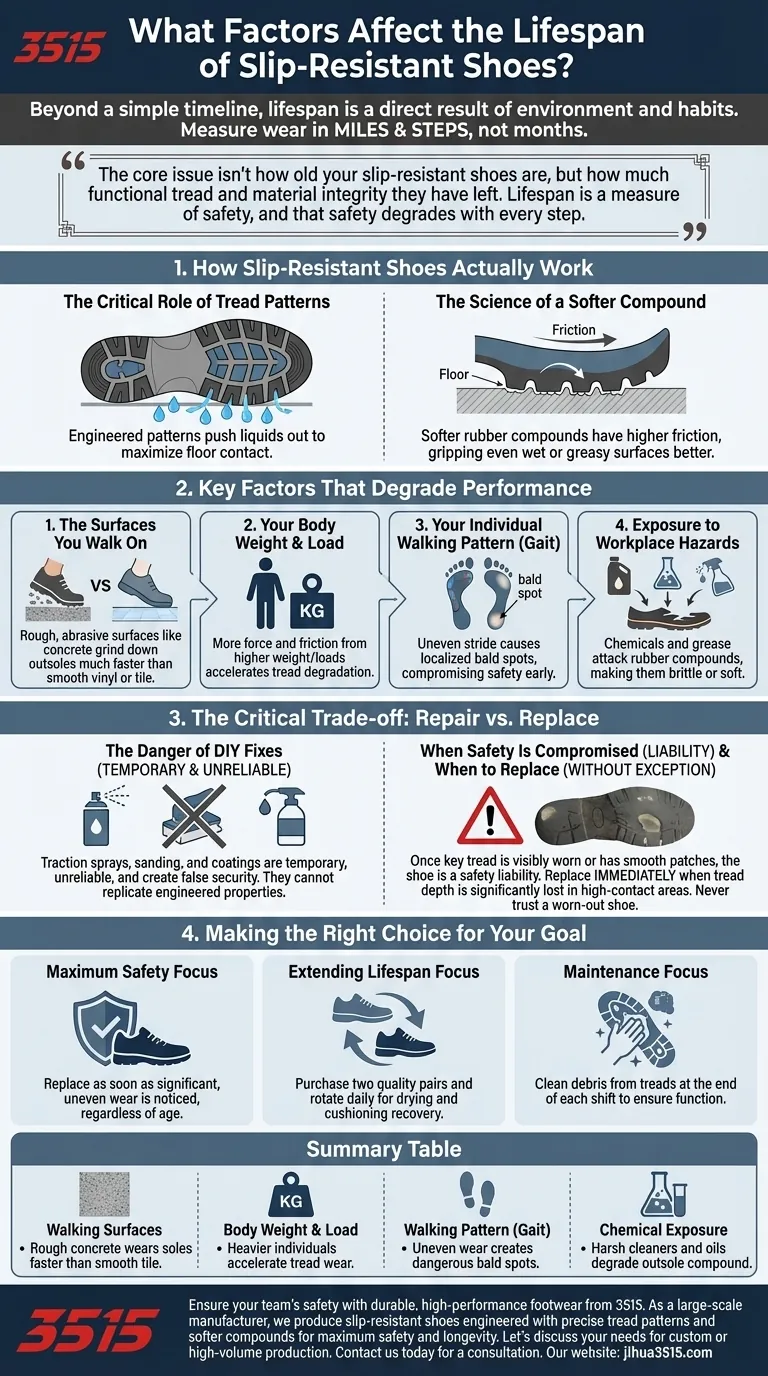

Beyond a simple timeline, the lifespan of a slip-resistant shoe is a direct result of the environment it's used in and the habits of the person wearing it. The most significant factors are the surfaces you walk on, your body weight, and your unique walking pattern, which is why measuring wear in miles or steps is a far more accurate gauge of a shoe's remaining life than counting months.

The core issue isn't how old your slip-resistant shoes are, but how much functional tread and material integrity they have left. Lifespan is a measure of safety, and that safety degrades with every step.

How Slip-Resistant Shoes Actually Work

To understand what wears a shoe out, you first need to understand what makes it effective. The magic is entirely in the outsole, the part that meets the floor.

The Critical Role of Tread Patterns

A slip-resistant outsole features specifically engineered tread patterns. These small grooves and channels are designed to push liquids like water and oil out from under the shoe, maximizing the surface area that makes direct contact with the floor.

The Science of a Softer Compound

Unlike standard shoes, slip-resistant footwear uses softer rubber or synthetic compounds. This softer material has a higher coefficient of friction, allowing it to better grip microscopic imperfections in a floor surface, even when wet or greasy.

Key Factors That Degrade Performance

Every shoe eventually wears out, but the rate of decline for safety footwear is tied directly to its working conditions.

The Surfaces You Walk On

The type of floor has the biggest impact. Walking consistently on rough, abrasive surfaces like concrete or asphalt will grind down the soft outsole material much faster than walking on smooth vinyl or tile floors found in kitchens and hospitals.

Your Body Weight and Load

Physics plays a direct role. A heavier individual exerts more force and friction with every step, leading to faster degradation of the tread. Carrying heavy loads regularly has the same accelerating effect on wear.

Your Individual Walking Pattern (Gait)

Few people have a perfectly balanced stride. Most of us wear down one part of the heel or sole more than others. This uneven wear can create a smooth "bald spot" on a critical area of the outsole, compromising the entire shoe's safety long before the rest of the tread is gone.

Exposure to Workplace Hazards

Chemicals, grease, and cleaning agents can attack the rubber compounds in an outsole. This can cause the material to become brittle or soft, reducing its frictional properties even if the tread pattern appears intact.

The Critical Trade-off: Repair vs. Replace

While it can be tempting to extend the life of a shoe, you must weigh the potential cost savings against the risk of injury.

The Danger of DIY Fixes

Methods like traction sprays, sanding the soles, or applying various coatings are temporary, unreliable fixes. They cannot replicate the engineered properties of the original outsole and can create a false sense of security.

When Safety Is Compromised

A slip-resistant shoe's primary function is safety. Once the key tread patterns are visibly worn down or the sole has smooth patches, the shoe can no longer channel away liquids effectively. At this point, it is a safety liability.

When to Replace, Without Exception

If you can see a significant loss of tread depth, especially in the high-contact areas of the heel and ball of the foot, the shoe must be replaced. Trusting a worn-out shoe is a risk that is never worth taking.

Making the Right Choice for Your Goal

Proactive inspection and care are the best tools for ensuring your footwear keeps you safe.

- If your primary focus is maximum safety: Replace your shoes as soon as you notice significant, uneven wear in the tread, regardless of their age.

- If your primary focus is extending lifespan: Purchase two quality pairs and rotate them daily, allowing each pair 24 hours to fully dry and for the cushioning to decompress.

- If your primary focus is maintenance: Make a habit of cleaning debris from the outsole treads at the end of each shift to ensure they can function as designed.

Ultimately, your safety depends on treating your footwear as critical equipment, not just an accessory.

Summary Table:

| Factor | Impact on Shoe Lifespan |

|---|---|

| Walking Surfaces | Rough concrete wears soles faster than smooth tile. |

| Body Weight & Load | Heavier individuals exert more force, accelerating tread wear. |

| Walking Pattern (Gait) | Uneven wear creates dangerous bald spots, compromising safety. |

| Chemical Exposure | Harsh cleaners and oils can degrade the outsole compound. |

Ensure your team's safety with durable, high-performance footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our footwear is engineered with the precise tread patterns and softer compounds discussed in this article to maximize safety and longevity in demanding environments.

Let's discuss your needs: Whether you require custom designs or high-volume production, our team is ready to provide a solution that protects your workforce and fits your supply chain.

Contact us today for a consultation and see how 3515 can be your trusted safety footwear partner.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.