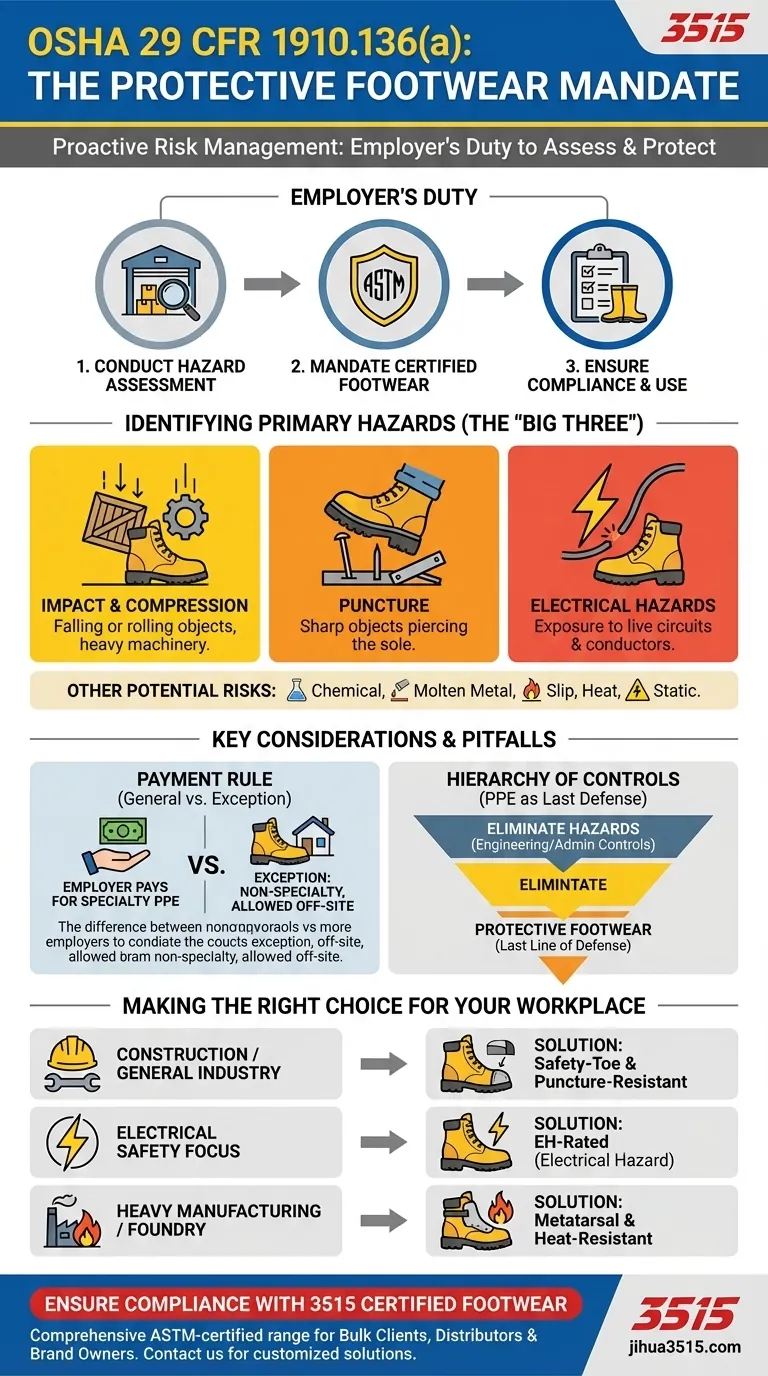

At its core, OSHA standard 29 CFR 1910.136(a) is a mandate for proactive risk management. This regulation requires employers to ensure their employees use protective footwear when working in any area where there is a danger of foot injuries. The standard specifically identifies risks from falling or rolling objects, objects that could pierce the sole of the shoe, and exposure to electrical hazards.

The standard places the responsibility squarely on the employer to first conduct a thorough hazard assessment of the workplace. Based on that assessment, the employer must then mandate and ensure the use of appropriate protective footwear designed to mitigate the identified risks.

The Employer's Duty: From Hazard Assessment to Implementation

Compliance with 29 CFR 1910.136(a) goes beyond simply telling employees to wear boots. It requires a systematic approach to identifying and neutralizing potential dangers to employees' feet.

Identifying the Core Hazards

The standard is built around three primary categories of risk. Your hazard assessment must look for evidence of:

- Impact and Compression: This involves the danger of heavy objects falling or rolling onto the foot. Think of warehouse environments, construction sites, or manufacturing floors where heavy materials or machinery are present.

- Puncture: This risk comes from sharp objects that could pierce the sole of a shoe, such as nails, scrap metal, or rebar on a job site.

- Electrical Hazards: This applies to work environments where employees could come into contact with live circuits or conductors, requiring footwear that can insulate against electric shock.

Beyond the "Big Three"

While the standard names three core hazards, a comprehensive assessment should also consider other potential dangers. OSHA recommends evaluating risks from corrosive materials, molten metal splashes, static electricity, and unusually hot or slippery surfaces.

Mandating Certified Footwear

The term "protective footwear" is not subjective. For footwear to be compliant, it must meet established industry standards, such as those set by ASTM International (formerly the American Society for Testing and Materials). This certification ensures the footwear has been tested and is proven to protect against specific hazards.

Common Pitfalls and Key Considerations

Simply providing footwear is not enough. True compliance involves understanding the nuances of the standard, particularly regarding financial responsibility and the hierarchy of controls.

The Question of Payment

One of the most common points of confusion is who pays for the footwear. While employers are generally required to pay for Personal Protective Equipment (PPE), OSHA provides a specific exception for certain types of safety-toe shoes.

An employer is not required to pay for non-specialty, safety-toe protective footwear if the employer permits those shoes to be worn off the job site. This typically applies to basic steel-toe boots that are not designed for a specialized work function.

Footwear as a Last Line of Defense

Protective footwear is a form of PPE, which is considered the last line of defense in workplace safety. The standard implies that employers must first try to eliminate or reduce foot hazards through engineering or administrative controls. When those dangers still remain, protective footwear becomes mandatory.

Making the Right Choice for Your Workplace

Your approach to compliance should be dictated by the specific, documented risks your employees face.

- If your primary focus is general industry or construction: Mandate footwear with certified safety-toes and puncture-resistant soles to guard against the most common impact and puncture hazards.

- If your primary focus is electrical safety: Require employees to use footwear specifically rated for Electrical Hazard (EH) protection to insulate against accidental shock.

- If your primary focus is heavy manufacturing or foundry work: Your hazard assessment will likely demand specialized footwear, such as metatarsal guards for top-of-foot protection or heat-resistant soles.

- If your primary focus is policy and compliance: Conduct and document a thorough hazard assessment to define exactly what protection is required and establish a clear, written policy on payment for non-specialty vs. specialty footwear.

A proactive and well-documented protective footwear program is the most effective way to protect your employees and ensure full compliance.

Summary Table:

| Key Aspect | OSHA 29 CFR 1910.136(a) Requirement |

|---|---|

| Core Mandate | Employers must ensure protective footwear is used where foot injury dangers exist. |

| Primary Hazards | Falling/rolling objects, sole punctures, and electrical hazards. |

| Employer Duty | Conduct a hazard assessment and provide certified protective footwear. |

| Footwear Standard | Must meet ASTM or equivalent certification for specific hazards. |

| Payment Rule | Employers generally pay for PPE, with exceptions for non-specialty safety-toe shoes worn off-site. |

Protect your workforce and ensure OSHA compliance with 3515's certified safety footwear. As a large-scale manufacturer, we produce a comprehensive range of ASTM-certified safety shoes and boots—including styles with safety toes, puncture-resistant soles, and EH ratings—for distributors, brand owners, and bulk clients. Our production capabilities cover all types of protective footwear tailored to your hazard assessment needs.

Contact us today to discuss your requirements and receive a customized solution that keeps your team safe and compliant.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- Why is safety footwear critical in power station construction? Compare Professional Protection vs. Regular Shoes

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry