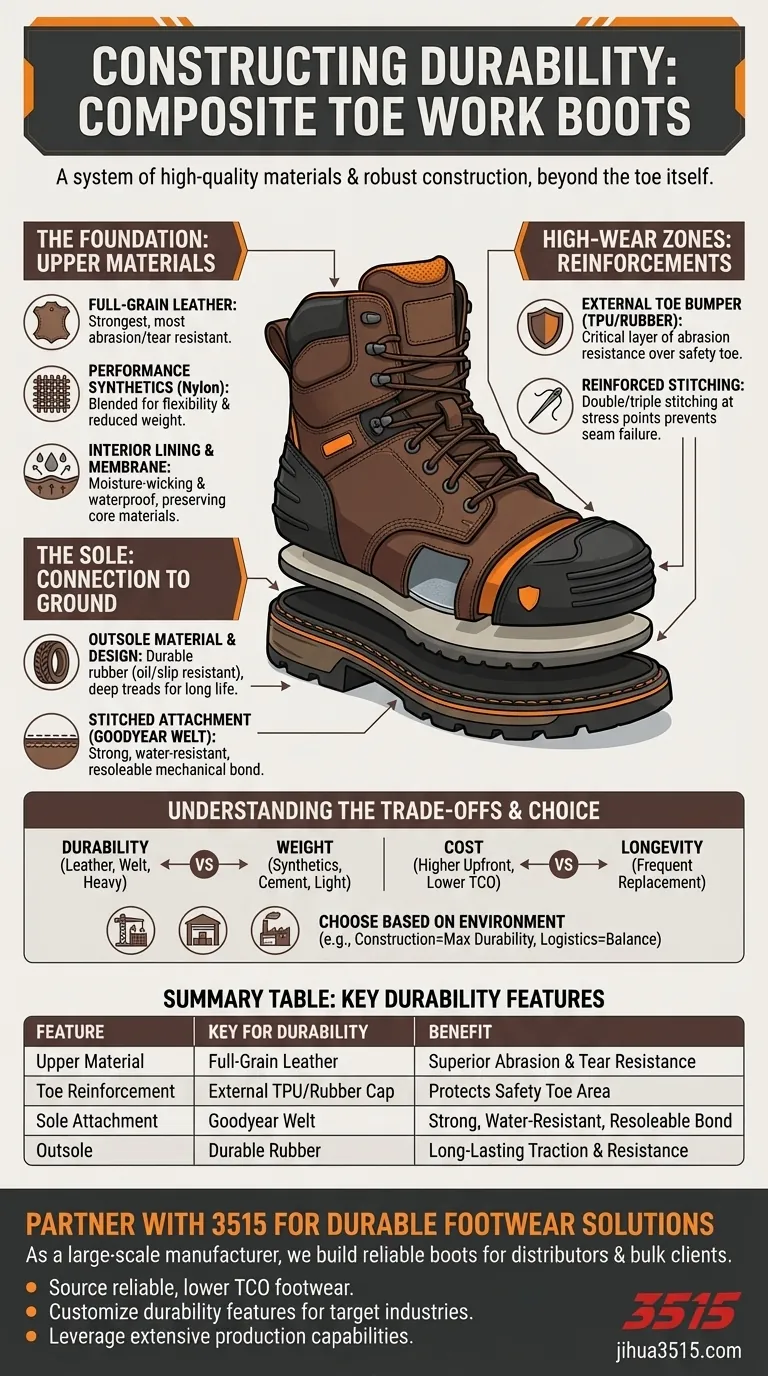

Beyond the composite toe itself, the most durable work boots are defined by the quality of their core materials and the robustness of their construction. True longevity comes from features like full-grain leather uppers, externally reinforced toe caps made of thermoplastic polyurethane (TPU), and rugged rubber outsoles that are both glued and stitched to the boot.

True boot durability isn't found in a single feature, but in a system of high-quality materials and robust construction methods. Focus less on marketing claims and more on the tangible evidence of construction: the type of leather, the reinforcement at wear points, and how the sole is attached.

The Foundation: Upper Materials

The upper is the main body of the boot and represents the first line of defense against wear and tear. Its material composition is a primary indicator of overall durability.

Why Full-Grain Leather is the Standard

Full-grain leather is the highest quality grade, using the strongest and most durable part of the animal hide.

Unlike corrected grains, it hasn't been sanded or buffed, so it retains its dense fiber structure. This makes it exceptionally resistant to abrasion and tearing.

The Role of Synthetic Materials

Modern boots often blend leather with high-performance synthetic fabrics like nylon.

These materials can reduce weight and increase flexibility. In high-wear areas, look for abrasion-resistant textiles that complement the leather without compromising the boot's structural integrity.

Protecting from the Inside Out

A boot's interior lining is also critical for its lifespan. A moisture-wicking lining pulls sweat away from the foot, preventing the internal materials from breaking down due to moisture saturation.

Similarly, a quality waterproof membrane keeps external water out while allowing internal vapor to escape, preserving the integrity of the leather and adhesives.

High-Wear Zones: Reinforcements Where It Counts

A durable boot is intelligently designed, with extra protection applied to the areas that take the most abuse.

External Toe Protection (The "Toe Bumper")

The area over the safety toe is often the first point of failure. Boots featuring an external thermoplastic polyurethane (TPU) or rubber toe cap add a critical layer of abrasion resistance.

This "bumper" protects the leather from being scuffed, cut, and worn through, dramatically extending the boot's usable life.

Reinforced Stitching

Look closely at the seams. High-quality boots use double or even triple stitching in critical stress areas, such as where the different parts of the upper join together. This prevents seams from splitting under heavy strain.

The Sole: Your Connection to the Ground

The outsole and the method used to attach it are arguably the most important factors in a boot's long-term durability and serviceability.

Outsole Material and Design

The best outsoles are made from a durable rubber compound specifically formulated to resist oil, chemicals, and slips.

A rugged design with deep treads or lugs not only provides superior traction but also means there is more material to wear down before the sole's performance is compromised.

The Critical Sole Attachment Method

How the sole is attached is a key differentiator. A basic "cement" construction simply glues the sole on, which is the least durable method.

For maximum durability, look for boots with a stitched construction, such as a Goodyear welt. This method stitches the upper to the sole, creating a mechanical bond that is far stronger and more water-resistant than glue alone. It also allows the boot to be resoled.

Understanding the Trade-offs

Choosing the right boot involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Durability vs. Weight

The most durable materials—full-grain leather, thick rubber outsoles, and welted construction—are also the heaviest. Lighter boots with synthetic uppers and cemented soles offer more flexibility and less fatigue but will almost always have a shorter lifespan.

Cost vs. Longevity

A higher upfront cost for features like a Goodyear welt and premium leather often translates to a lower total cost of ownership. These boots last significantly longer and can often be repaired or resoled, avoiding the need for frequent replacement.

Making the Right Choice for Your Goal

When evaluating a boot, prioritize the features that align with the specific demands of your work environment.

- If your primary focus is maximum longevity in abrasive environments (construction, masonry): Prioritize full-grain leather, a Goodyear welt sole attachment, and an external TPU or rubber toe cap.

- If your primary focus is a balance of mobility and durability (logistics, light industrial): Look for a combination of leather and high-denier nylon with a securely glued and stitched rubber outsole.

- If your primary focus is protection from chemicals (mechanics, manufacturing): Ensure the outsole is explicitly rated for oil and chemical resistance and the upper is made from a material that can be easily cleaned.

A well-constructed boot is an investment in your safety and a tool for your trade; understanding its construction is the key to making a wise one.

Summary Table:

| Feature | Key for Durability | Benefit |

|---|---|---|

| Upper Material | Full-Grain Leather | Superior abrasion and tear resistance. |

| Toe Reinforcement | External TPU/Rubber Cap | Protects the safety toe area from wear. |

| Sole Attachment | Goodyear Welt Construction | Creates a strong, water-resistant, resoleable bond. |

| Outsole | Durable Rubber Compound | Resists oil, chemicals, and provides long-lasting traction. |

Ready to Invest in Durable Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance work boots built to last. We specialize in creating footwear with the exact durability features discussed—from premium full-grain leather uppers to robust, stitched construction—for distributors, brand owners, and bulk clients.

Partner with us to:

- Source reliable footwear that reduces replacement cycles and lowers the total cost of ownership for your customers.

- Customize boots with specific durability features tailored to the unique demands of your target industries (e.g., construction, logistics, manufacturing).

- Leverage our extensive production capabilities across all types of safety shoes and boots.

Let's discuss how we can build a durable footwear solution for your business. Contact our team today for a consultation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene