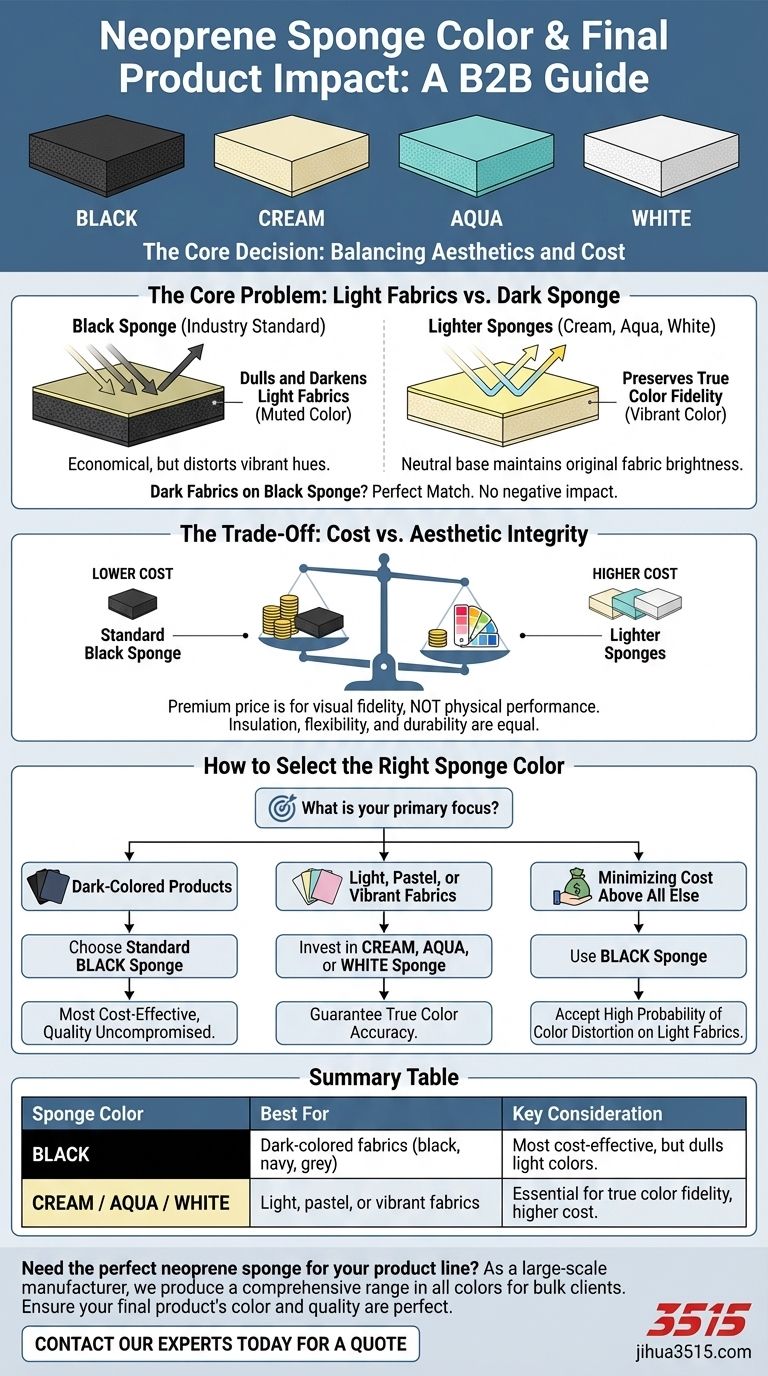

For product designers and material specifiers, understanding the base material is critical. Neoprene sponge is primarily available in four colors: black, cream, aqua, and white. The choice is not merely aesthetic; the color of the inner sponge directly impacts the visual integrity of the final laminated fabric, especially when working with lighter colors.

The core decision comes down to a trade-off: The standard black sponge is cost-effective but can distort light-colored fabrics, while more expensive lighter sponges are essential for preserving true color fidelity.

The Sponge's Role in Color Fidelity

The neoprene sponge forms the core of your final material. While it's covered by fabric, its base color can subtly "show through," influencing the final appearance.

Black Sponge: The Industry Standard

The vast majority of neoprene sponge produced is black. It is the most common and generally the most cost-effective option.

For projects using black, dark grey, navy, or other deep-colored fabrics, the black sponge is a perfect and economical choice. Its dark base will not negatively affect the final look.

The Challenge with Light-Colored Fabrics

Using a black sponge core with a light-colored fabric—such as white, yellow, or pastels—creates a significant problem.

The dark base of the sponge can dull and darken the laminated fabric, making vibrant colors appear muted and whites look greyish. This distortion can compromise the entire design intent of the product.

Lighter Sponges: Preserving True Color

To solve this problem, manufacturers offer sponges in cream, aqua, and white. These options provide a neutral or light-colored base.

When a light fabric is laminated over a cream or white sponge, its original brightness and hue are maintained. This ensures the final product's color is accurate and vibrant, exactly as designed.

Understanding the Trade-offs

Choosing the right sponge color requires balancing visual requirements with budget constraints. The decision is almost entirely driven by the color of your outer fabric.

Cost vs. Aesthetic Integrity

There is a clear cost difference. Lighter-colored sponges like cream, aqua, and white are more expensive to produce than standard black.

This price premium is the trade-off for achieving color accuracy in the final product. For high-end consumer goods where color is a key selling point, this extra cost is a necessary investment.

Performance Implications

It is critical to note that the color of the sponge has no impact on its physical performance.

Insulation, flexibility, and durability are determined by the rubber compound itself, not its pigment. The choice is purely a matter of visual outcome.

How to Select the Right Sponge Color

Your selection should be a direct function of your project's specific design goals and fabric choices.

- If your primary focus is dark-colored products: Choose the standard black sponge to achieve the most cost-effective result without compromising quality.

- If your primary focus is light, pastel, or vibrant fabrics: Invest in a cream, aqua, or white sponge to guarantee the color accuracy of your final product.

- If your primary focus is minimizing cost above all else: You can use black sponge, but you must accept the high probability of color distortion on any light-colored fabrics.

Making an informed choice about your core material is the foundation of a successful final product.

Summary Table:

| Sponge Color | Best For | Key Consideration |

|---|---|---|

| Black | Dark-colored fabrics (black, navy, grey) | Most cost-effective, but dulls light colors |

| Cream / Aqua / White | Light, pastel, or vibrant fabrics | Essential for true color fidelity, higher cost |

Need the perfect neoprene sponge for your product line? As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality neoprene sponge in all colors (black, cream, aqua, white) for distributors, brand owners, and bulk clients. We ensure your final product's color and quality are perfect. Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- What is the purpose of using lightweight synthetic ropes in ankle exoskeletons? Enhancing Torque and User Agility

- How can a footwear manufacturer utilize product variety to enhance competitive barriers? Drive Growth in Digital Trade

- How does a UPS expansion board enhance mobile smart footwear stability? Powering Reliable Wearable Health Monitoring

- How does leg insulation affect foot warmth during winter cycling? Keep Your Feet Warm with Proper Body Heat Management

- What are the strategic considerations for selecting showroom visitors as research subjects in footwear consumer behavior?

- How do ERP and CRM systems coordinate digital transformation in textile and footwear? Boost Your Supply Chain Agility

- What are the differences between regular and wide boot sizes? A Guide to Perfect Fit and Comfort

- How do disposable protective clothing, caps, and shoe covers function as a technical barrier in clinical settings?